Array substrate and production method thereof, as well as display device

A technology of an array substrate and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problem that the shading area cannot be effectively used, and achieve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

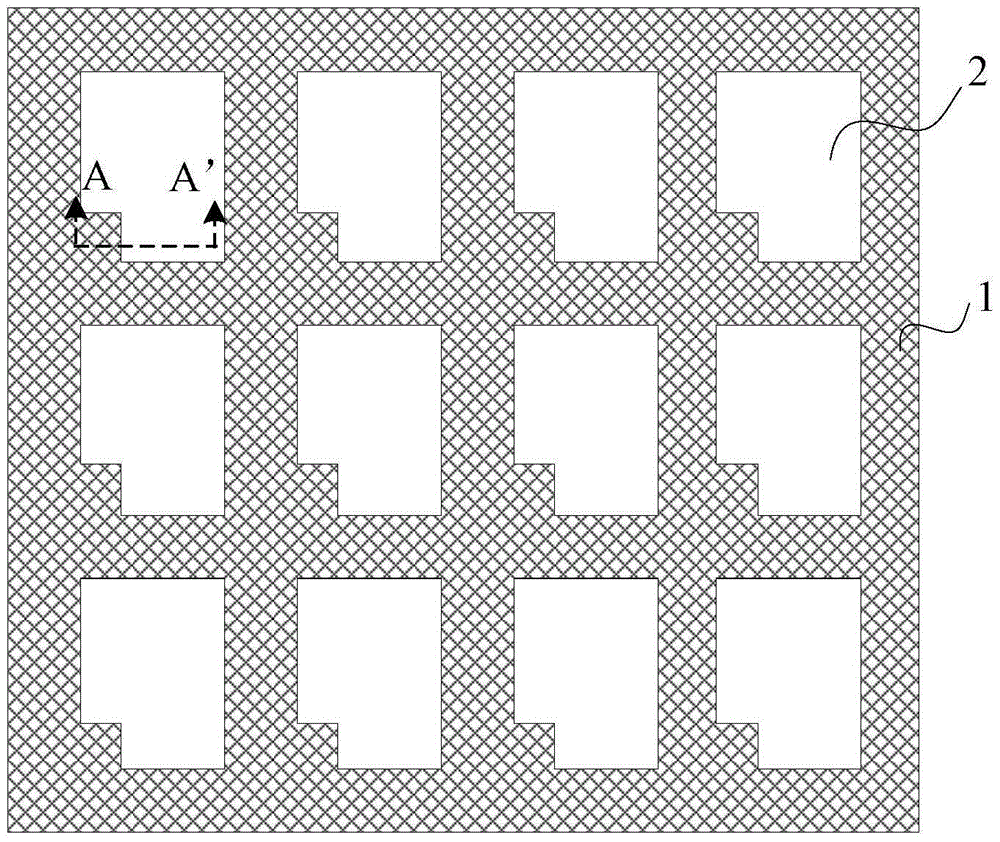

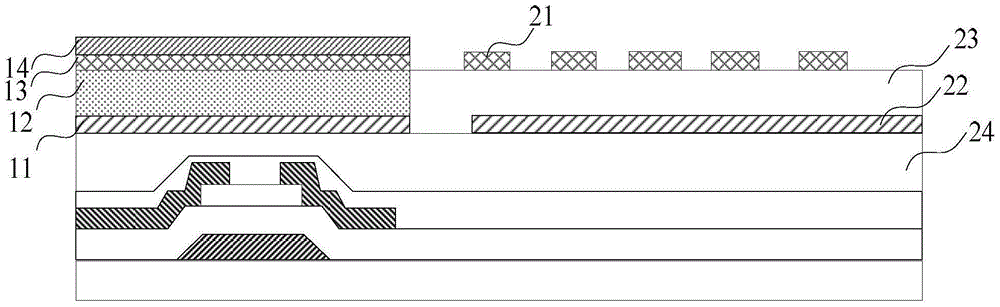

[0026] Embodiments of the present invention provide an array substrate, such as figure 1 and figure 2 As shown, the array substrate includes a plurality of light-transmitting regions 2, and a light-shielding region 1 surrounding each light-transmitting region 2. The light-shielding region 1 includes a first electrode 11, a photoelectric conversion film 12, and a second electrode 13 stacked in sequence. , the first electrode 11, the photoelectric conversion film 12 and the second electrode 13 constitute a photoelectric conversion unit, wherein the first electrode 11 is a transparent electrode.

[0027] It should be noted that the photoelectric conversion film 12 includes an N-type semiconductor film and a P-type semiconductor film, and the N-type semiconductor film and the P-type semiconductor film form a PN junction; in addition, the photoelectric conversion film 12 can also include an N-type semiconductor film and a P-type The I-type semiconductor film between the semicondu...

Embodiment 2

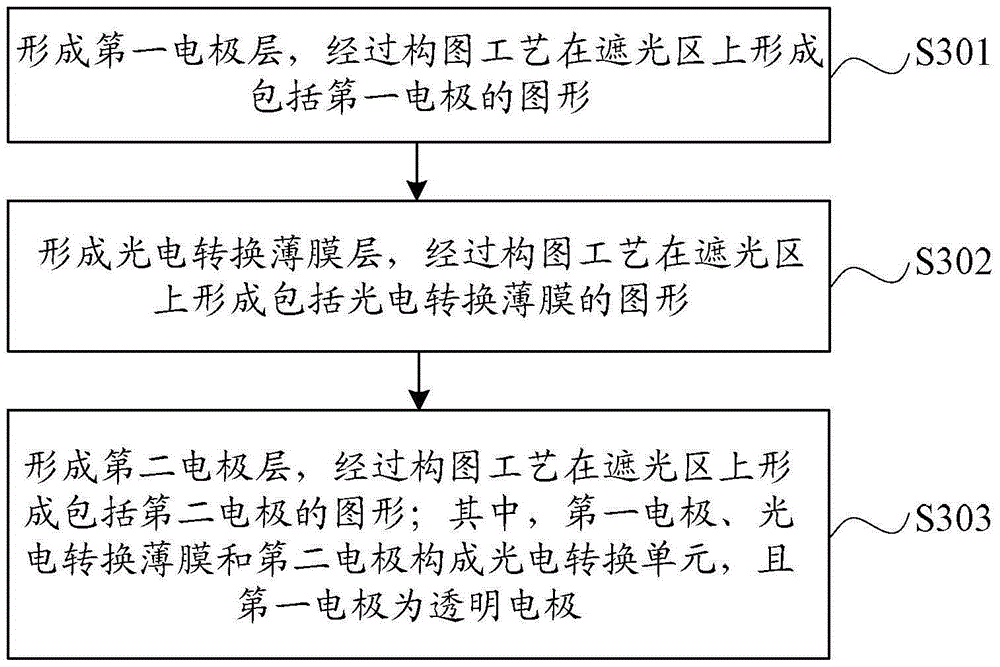

[0044] An embodiment of the present invention provides a method for fabricating an array substrate. The array substrate includes a plurality of light-transmitting regions and a light-shielding region surrounding each light-transmitting region, such as image 3 As shown, the method includes:

[0045] Step S301, forming a first electrode layer, and forming a pattern including the first electrode on the light-shielding region through a patterning process. Exemplarily, a first electrode layer is formed by methods such as plasma-enhanced chemical vapor deposition, sputtering or thermal evaporation, a photoresist is coated on the first electrode layer, and a mask plate having a pattern of the first electrode is used to cover The first electrode layer coated with photoresist is subjected to exposure, development, etching and other steps to form a pattern including the first electrode on the light-shielding area.

[0046] Step S302, forming a photoelectric conversion thin film layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com