A production management system and its control method

A technology of production management system and control method, which is applied in the direction of program control, comprehensive factory control, electrical program control, etc. It can solve the problems of time-consuming and laborious replacement of paper process cards, low-quality products, and disordered versions, etc., and improve the utilization of man-hours The effect of efficiency and production efficiency, standardization of production process flow, and improvement of production process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

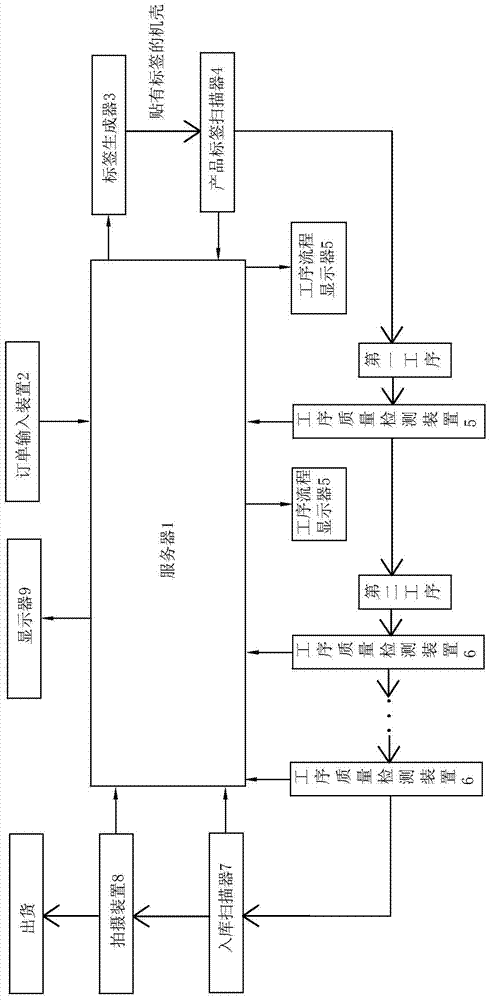

[0029] Such as figure 1 As shown, a production management system is characterized in that it includes a server 1, the server 1 is connected to an order input device 2 for inputting product type information and quantity information, and is used to generate corresponding product labels according to product type information and quantity information A label generator 3, a product label scanner 4 for scanning the label information and reading the product process of the server 1 according to the label information, a plurality of process flow displays 5 arranged in each process and used to display the production of the corresponding process, and a plurality of The process quality inspection device 6 that is arranged in each process and is used to detect the product quality of each process, is used to read the statistical information of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com