Production management and control system

A control system and product technology, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of time-consuming and laborious replacement of paper process cards, disordered versions, high costs, etc., to improve the utilization rate of man-hours and production efficiency , to achieve effectiveness, to make up for abnormal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and implementation process of the present invention, further describe in detail:

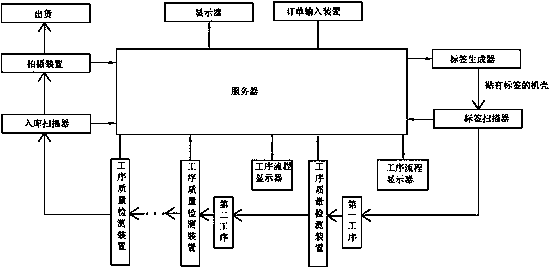

[0017] like figure 1 As shown, the label takes a one-dimensional barcode as an example, and the information such as the product type and product quantity of the order is input to the server through the order input device; the server generates a one-dimensional barcode corresponding to the product type and product quantity through the label generator, and the one-dimensional barcode is pasted On the product casing; when the casing is transmitted to the label scanner and scanned by it, the process flow display of each process on the production line displays the production process corresponding to the process, and at the same time the process flow display can also change the assembly process by playing Pay attention to the video or picture, which greatly improves the accuracy of the process assembly; the casing is transmitted to the first proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com