LED display calibration method

A technology of LED display screen and calibration method, which is applied to static indicators, instruments, etc., can solve the problems of low calibration efficiency and long time required, and achieve the effects of improving calibration efficiency, shortening calibration time, and reducing the number of image acquisitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

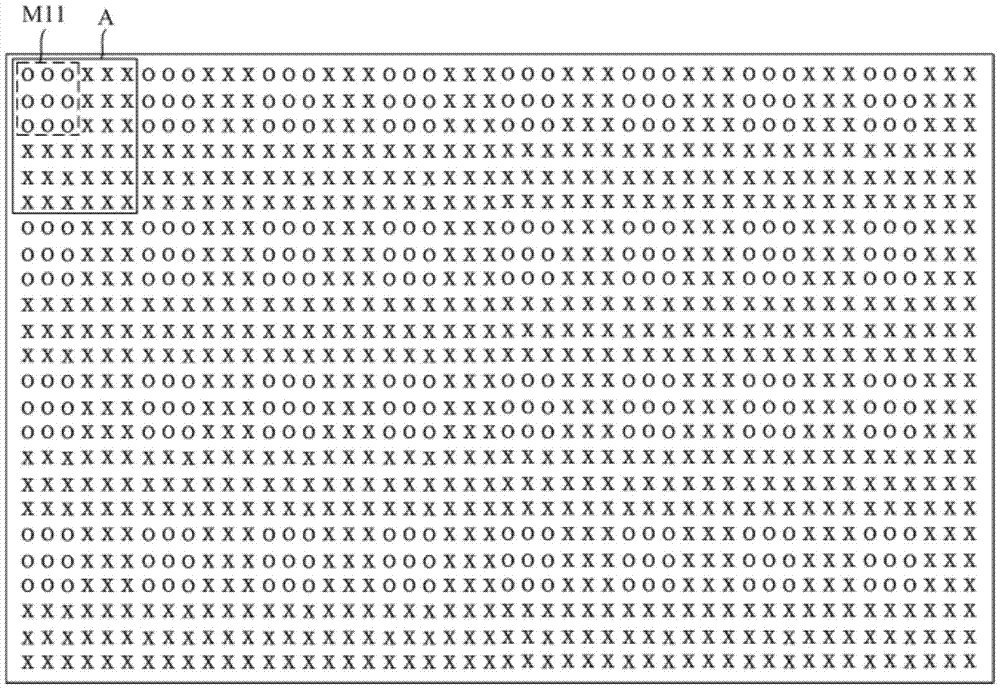

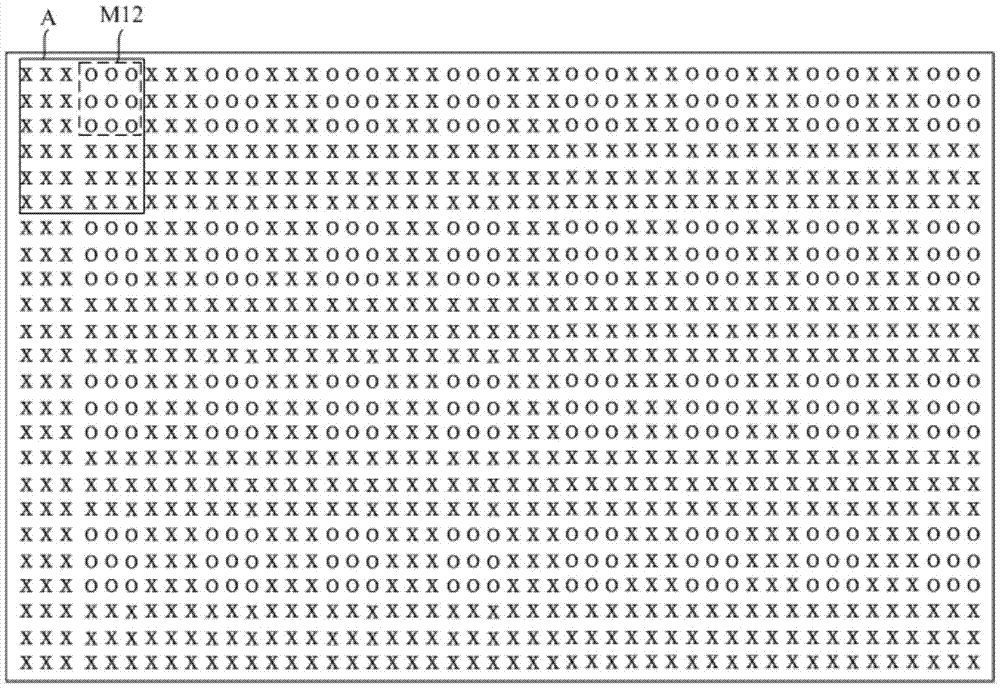

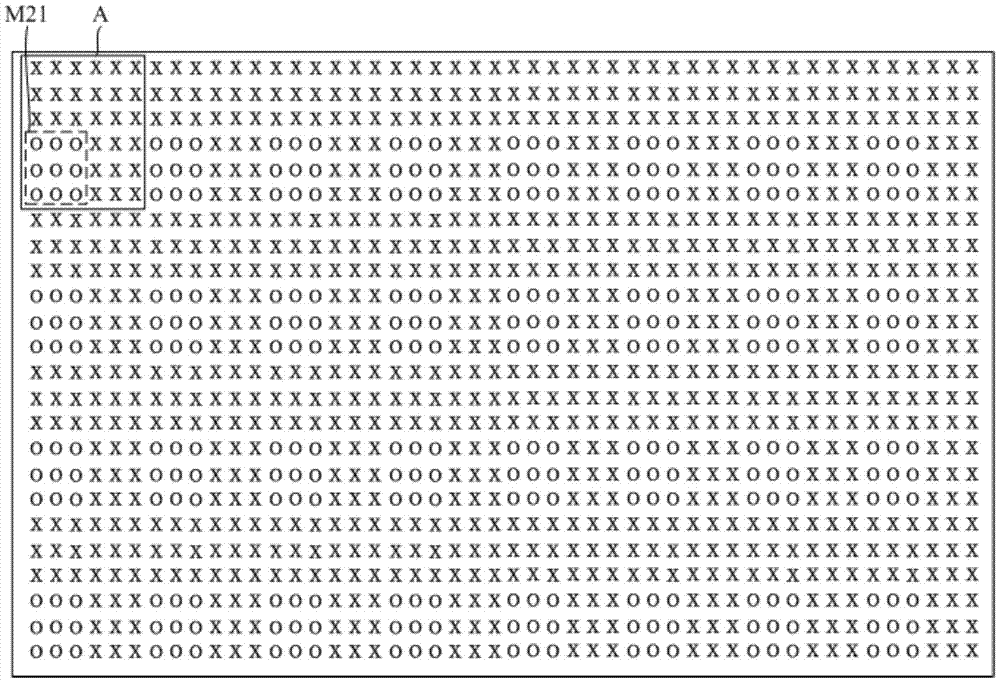

[0019] In order to shorten the correction time and improve the correction efficiency, the embodiment of the present invention proposes a method for correcting LED display screens based on the collection of partition modules, which is a method of increasing the number of LED light points in a single collection and reducing the number of image collection times, as follows :

[0020] First of all, according to the resolution of the LED display screen and the on-site conditions of the image acquisition equipment such as the shooting distance of the CCD camera, as well as the user's demand for the accuracy of the corrected effect, determine the corresponding calibration module size and module acquisition mode, such as 2K resolution LED For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com