Photovoltaic solar cell module ribbon

A technology for solar cells and welding strips, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as reducing the conductivity of the welding surface, increasing the manufacturing cost and difficulty of welding strips, and prone to false welding, and improving the power of components. , Improve welding contact and reduce the effect of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Picture 1-1 As shown, the photovoltaic solar cell module ribbon includes a ribbon body 1, and the front and back surfaces of the ribbon body 1 are both plane.

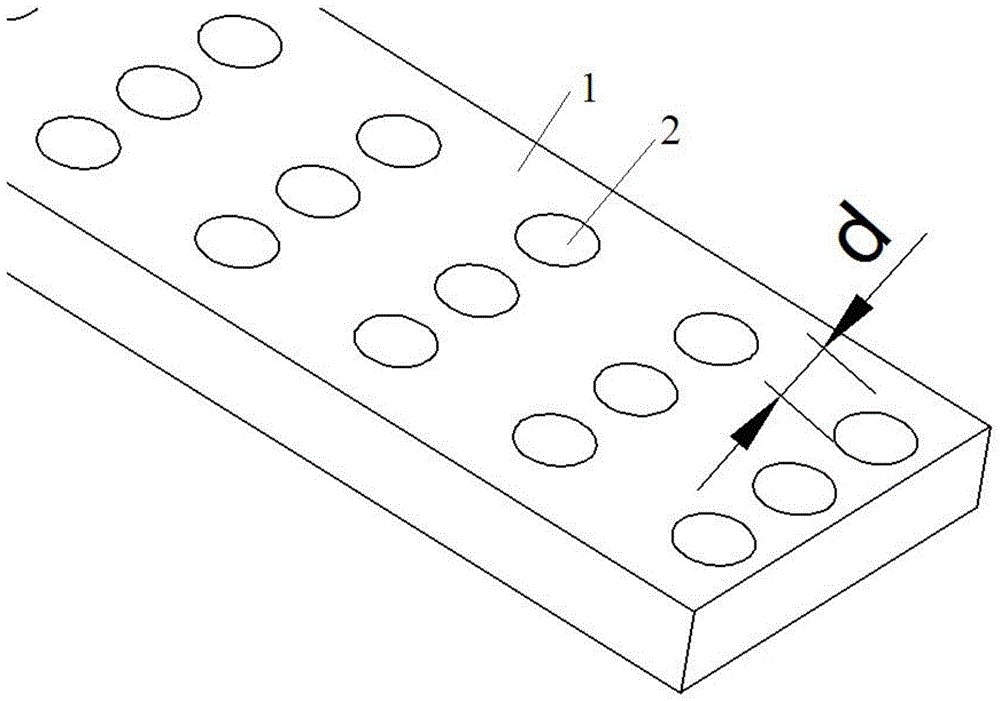

[0032] Such as Figure 1-2 As shown, through-holes 2 of various sizes and shapes can also be processed on the welding ribbon body 1 by rolling or stamping, and the through-holes 2 are arranged side by side in the width direction of the welding ribbon body 1. The diameter d of the through hole 2 is 0.1-0.5mm.

Embodiment 2

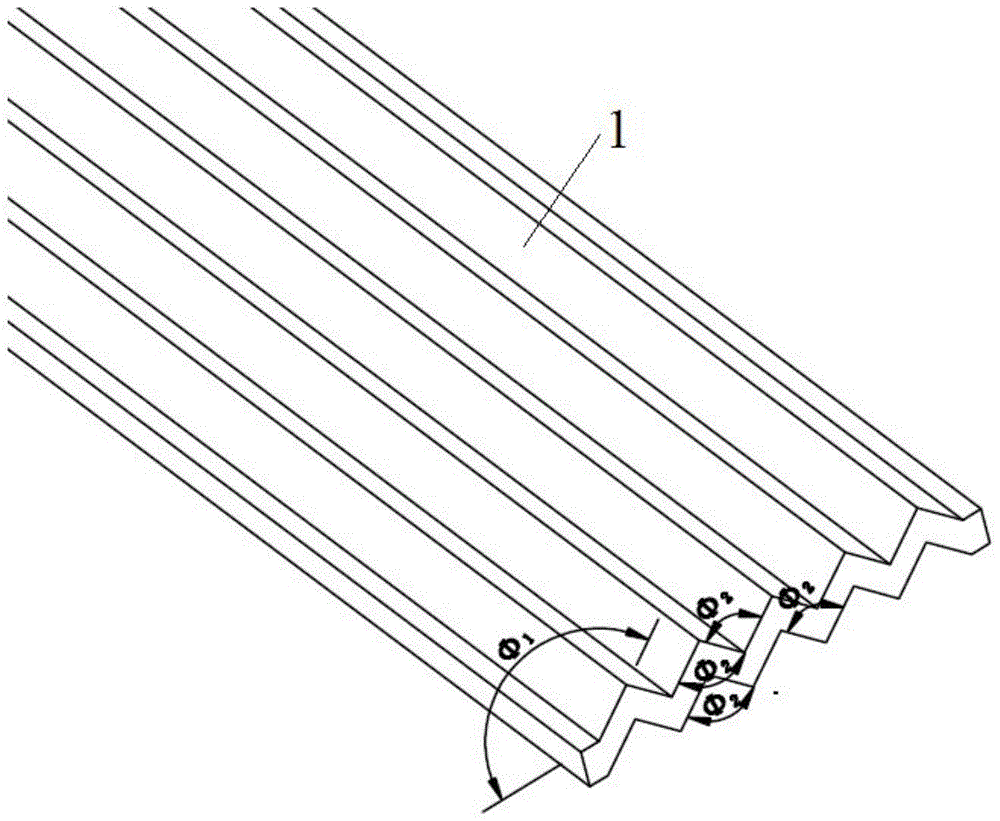

[0034] Such as figure 2 As shown, the photovoltaic solar cell module welding ribbon includes a ribbon body 1, and the front and back sides of the ribbon body 1 are sawtooth surfaces with the same shape and size; The number of saw teeth is 5-12, the saw tooth depth is 0.1-0.3mm, the included angle Φ1 between the saw tooth surface and the surface of the ribbon body 1=140°~170°, the sawtooth angle Φ2 of the front and back of the ribbon body 1 =110°~130°.

Embodiment 3

[0036] Such as image 3 As shown, through holes 2 of various sizes and shapes are processed on the ribbon body 1 described in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com