Magnetic shielding device for shaft-diameter-cut multi-directional evacuation flux leakage at the end of turbogenerator

A technology of turbo generator and shielding device, which is applied in the direction of shielding electromagnetic fields, etc., and can solve the problems that the effective dispersion of magnetic flux leakage at the end of the generator cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

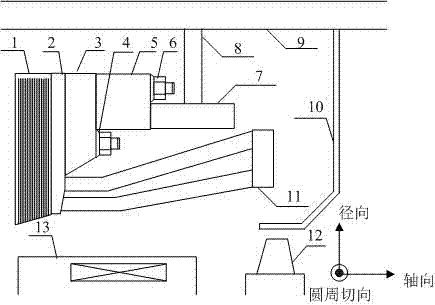

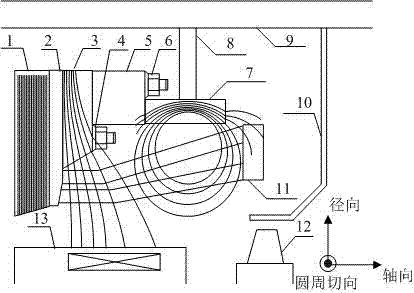

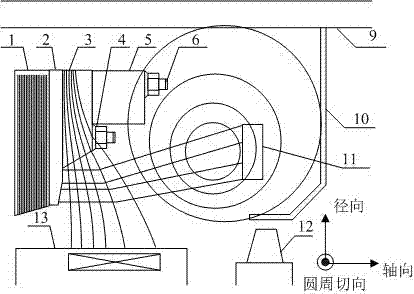

[0017] Specific implementation mode one: combine Figure 1-8 Describe this embodiment, the shaft-diameter-cut multi-directional cooperative magnetic shielding device for evacuating magnetic flux leakage at the end of the turbogenerator in this embodiment needs to add an axial-radial magnetic shielding device (7) at the end of the generator , realize the integration of the axial-radial magnetic shielding device (7) and the traditional radial-tangential magnetic shielding device (3), and evacuate the generator magnetic flux leakage from multiple directions, so as to prevent the iron core (1) at the end of the stator And the stator casing (9) and the end baffle cover (10) are disturbed by the end parasitic magnetic flux leakage.

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1-3 Describe this embodiment, the shielding device (3) of radial-tangential magnetization at the end of the generator described in this embodiment mainly absorbs the path from the rotor side (13) in the end area to the core (1) at the end of the stator The leakage flux on the generator end shaft-radial magnetic shielding device (7) is used to absorb the annular magnetic flux leakage generated by the stator end winding (11) in the end space when the generator is running; the end shaft - The shielding device (7) for radial magnetic conduction is arranged on the outer side of the stator end winding (11), at a certain distance from the stator casing (9) and the end baffle cover (10). The axial-radial magnetically conductive shielding device (7) guides the annular magnetic flux leakage generated by the stator end winding (11), and also plays a role in evacuating the radial-tangential magnetically conductive shielding devi...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 2 , 4 5. Describe this embodiment. The axial-radial magnetically permeable shielding device (7) added at the end of the generator described in this embodiment is formed by stacking rectangular cold-rolled silicon steel sheets (14) along the circle. There is a rectangular hole (19) in the middle of the punched sheet of the rolled silicon steel sheet (14), and through the rectangular hole (19), the rectangular cold-rolled silicon steel sheet (14) is inserted one by one along the circumferential direction into the ring rod (15) with a certain gap. ), after the set is completed, seal the gaps at both ends of the ring rod (15) with sleeves, and each rectangular cold-rolled silicon steel sheet (14) has a binding opening (20) at the corner, through which the binding opening (20) Insert metal binding strips to compress each stacked segment, and then install the axial-radial magnetic shielding device (7) on the outer side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com