Device and method for producing a spring made of fiber composite material

A technology for fiber composite materials, equipment, processing devices for laminated bundles, springs. In the field of molding, it can solve the problems of molding mold pollution, long downtime, high cleaning costs, etc., and achieve the effect of accelerating the molding process, reducing the saving, saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

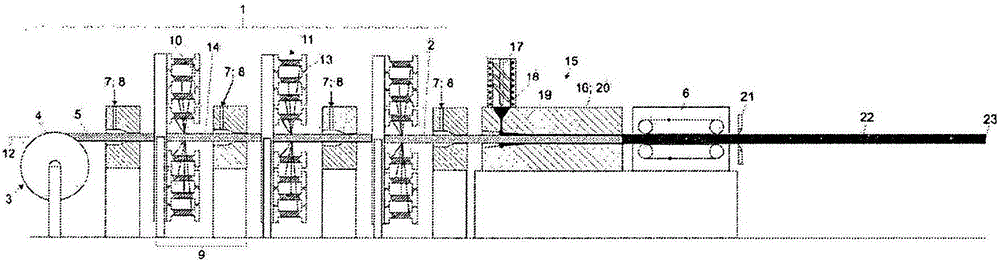

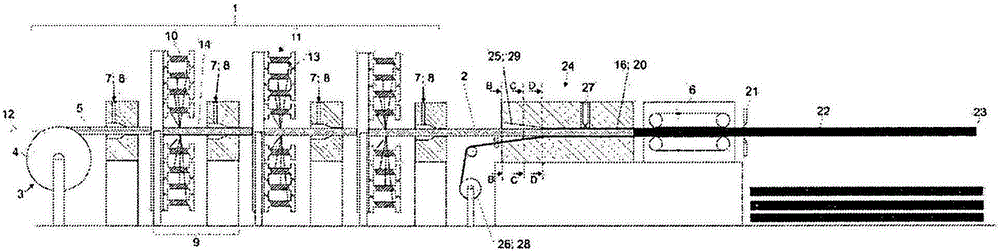

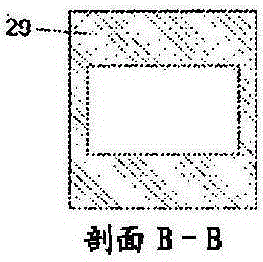

[0069] figure 1 A first section of the device according to the invention for producing a spring 34 from fiber composite material according to a first exemplary embodiment is shown.

[0070] The first section of the plant comprises a wet winding device 1 as a processing device 1 for preparing an impregnated fiber bundle 2 (lamination bundle), a coating unit 15 for forming a protective sheath 16, a push lamination Conveyor unit 6 and slitting device for bundle 2.

[0071] The processing device 1 for producing laminated bundles 2 comprises a draw-off unit 3 with a storage roller 4 equipped with a flexible bundle-shaped spring core or core element 5, from which a conveying unit 6 continuously draws Take out the spring core. The bundle-shaped spring core 5 is made of plastic in the present exemplary embodiment and has a circular cross section.

[0072] The drawn flexible spring core 5 is wetted with the matrix material 8 by means of the first impregnation system 7 .

[0073] It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com