Rotary ash removal filter

A filter and dust removal technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of incomplete pulse dust removal, large area occupied by cloth bags, and insufficient strength, etc., to improve dust removal Efficiency, maintenance cost reduction, and the effect of increasing the active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

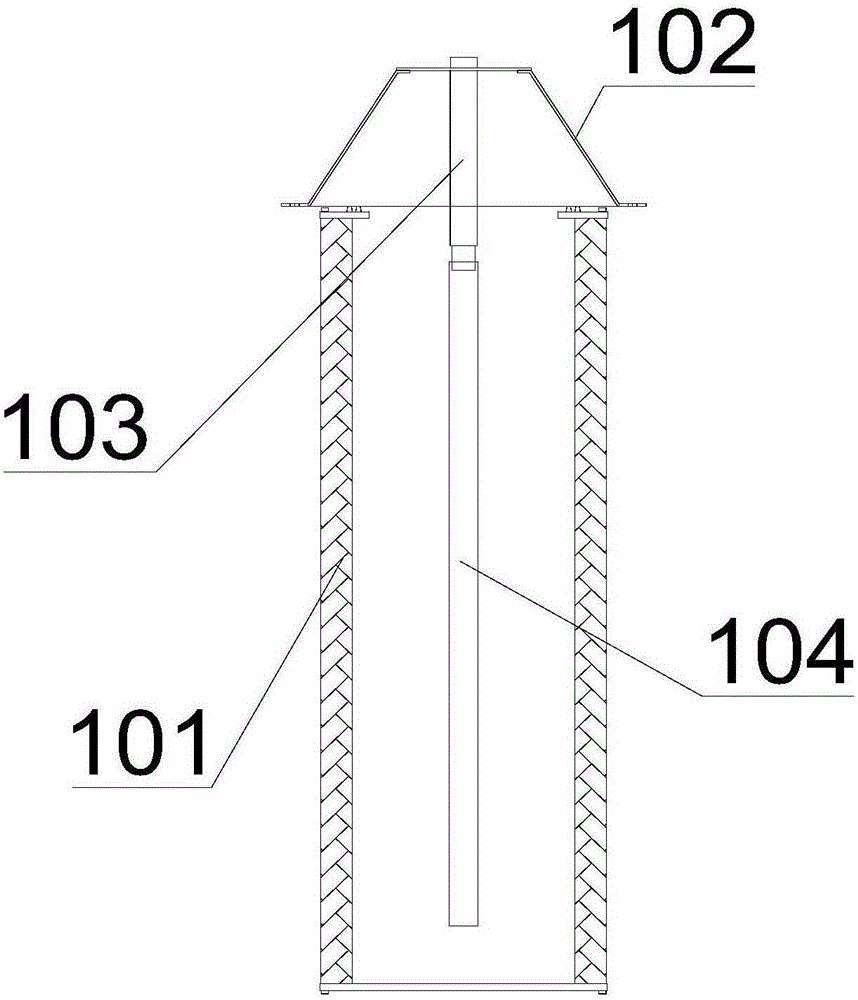

[0031] refer to figure 1 , this embodiment provides a rotary soot removal filter for filtering gas, and at the same time, it can also use gas for cleaning, so that the rotary soot removal filter has self-cleaning ability, and the rotary soot removal filter The service life is greatly improved.

[0032] The rotary dust removal filter includes: a support frame 102 , a cylindrical multi-fold filter element 101 , an air inlet pipe 103 and a blowpipe 104 for conveying gas. Wherein, one end of the multi-fold filter core 101 is provided with a ventilation opening, the blowpipe 104 is positioned in the multi-fold filter core 101, and one end of the multi-fold filter core 101 provided with a ventilation opening is connected with the support frame 102, and the other end of the multi-fold filter core 101 is far away from the support frame, One end of the air pipe 103 is located in the support frame, and the other end of the air inlet pipe 103 is located in the multi-fold filter element ...

Embodiment 2

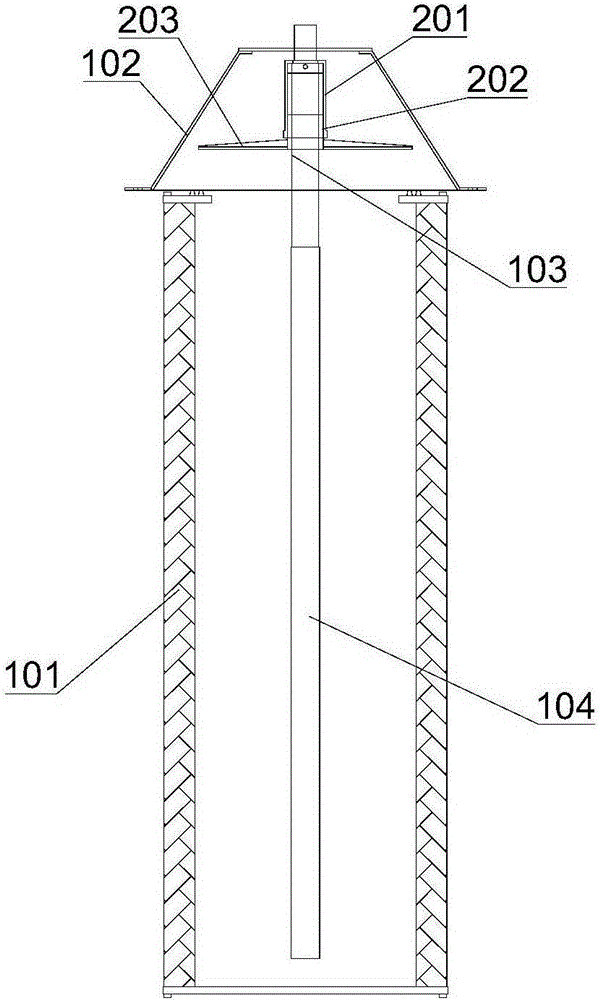

[0037] refer to figure 2 , this embodiment provides a rotary soot cleaning filter, which includes: a support frame 102 , a cylindrical multi-fold filter element 101 , an air inlet pipe 103 for conveying gas, and a blowpipe 104 . Wherein, one end of the multi-fold filter core 101 is provided with a ventilation opening, the blowpipe 104 is positioned in the multi-fold filter core 101, and one end of the multi-fold filter core 101 provided with a ventilation opening is connected with the support frame 102, and the other end of the multi-fold filter core 101 is far away from the support frame, One end of the air pipe 103 is located in the support frame, and the other end of the air inlet pipe 103 is located in the multi-fold filter element 101 and is rotatably connected with the blowpipe 104 .

[0038] Preferably, the rotary soot cleaning filter also includes a one-way closing valve, which can close the ventilation opening when gas is input from the intake pipe 103 . The setting...

Embodiment 3

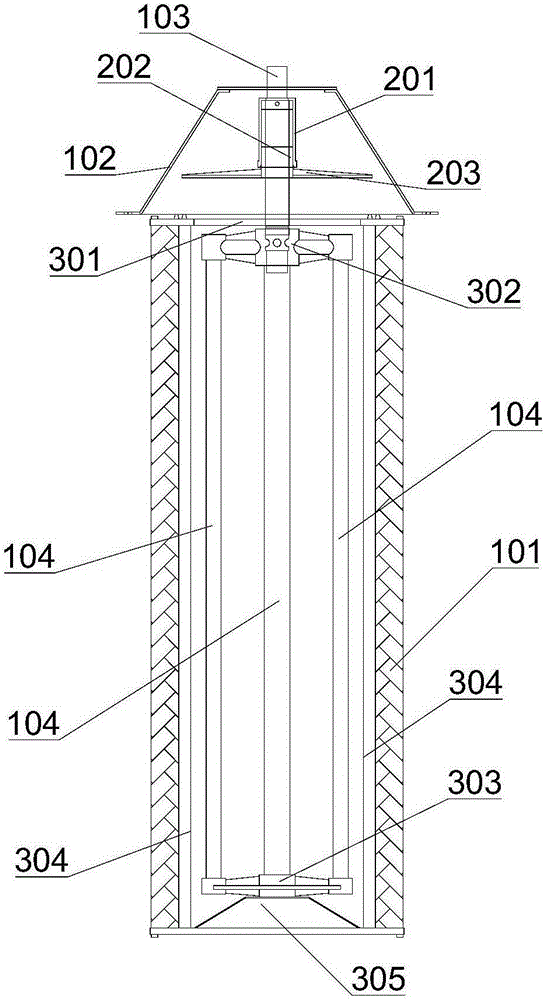

[0041] refer to image 3 , this embodiment provides a rotary soot cleaning filter, which includes: a support frame 102 , a cylindrical multi-fold filter element 101 , an air inlet pipe 103 for conveying gas, and a blowpipe 104 . Wherein, one end of the multi-fold filter core 101 is provided with a ventilation opening, the blowpipe 104 is positioned in the multi-fold filter core 101, and one end of the multi-fold filter core 101 provided with a ventilation opening is connected with the support frame 102, and the other end of the multi-fold filter core 101 is far away from the support frame, One end of the air pipe 103 is located in the support frame, and the other end of the air inlet pipe 103 is located in the multi-fold filter element 101 and is rotatably connected with the blowpipe 104 . The blowpipe 104 and the air inlet pipe 103 can be connected by bearings, so that the rotation resistance of the blowpipe 104 is small, and the rotation of the blowpipe 104 is faster.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com