Damping device of crusher

A technology of shock absorbing device and crusher, which is applied in non-rotational vibration suppression, grain processing and other directions, can solve the problems of complicated structure, high installation requirements and inconvenient installation of shock absorbing device, achieve simple structure, improve shock absorbing effect, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments.

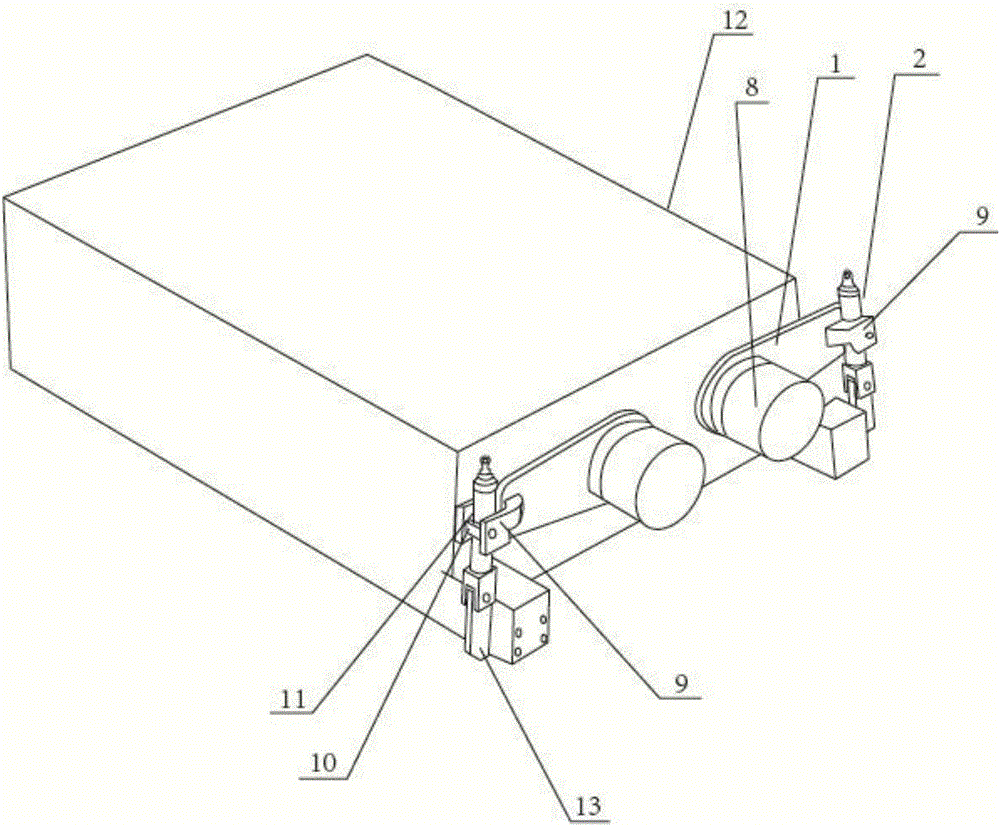

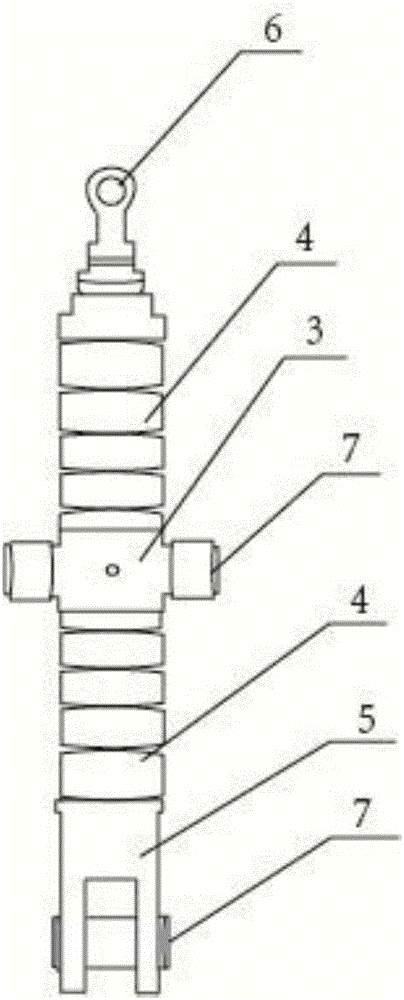

[0019] Such as figure 1 , 2 As shown, a shock-absorbing device for a crusher includes a shock-absorbing arm 1 and a shock-absorbing column 2, and the shock-absorbing column 2 includes a middle fixed column 3, a spring 4, a tail fixed column 5, and a hand ring 6. The spring 4 is arranged between the handle ring 6, the middle fixed column 3, and the tail fixed column 5. The middle fixed column 3 and the tail fixed column 5 are provided with transparent support holes, and connecting bolts 7 can be inserted into the support holes. One end of the shock absorbing force arm 1 is sleeved on the crushing shaft 8, and both sides of the other end of the shock absorbing force arm 1 are provided with arc-shaped splints 9. Preferably, the arc-shaped splints 9 are welded to the The shock-absorbing force arm 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com