Lateral drive shaft of drive train of motor vehicle comprising internal combustion engine and transducer

A powertrain, lateral drive technology used in vehicle components, transport and packaging, controls, etc. to address issues such as comfort impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

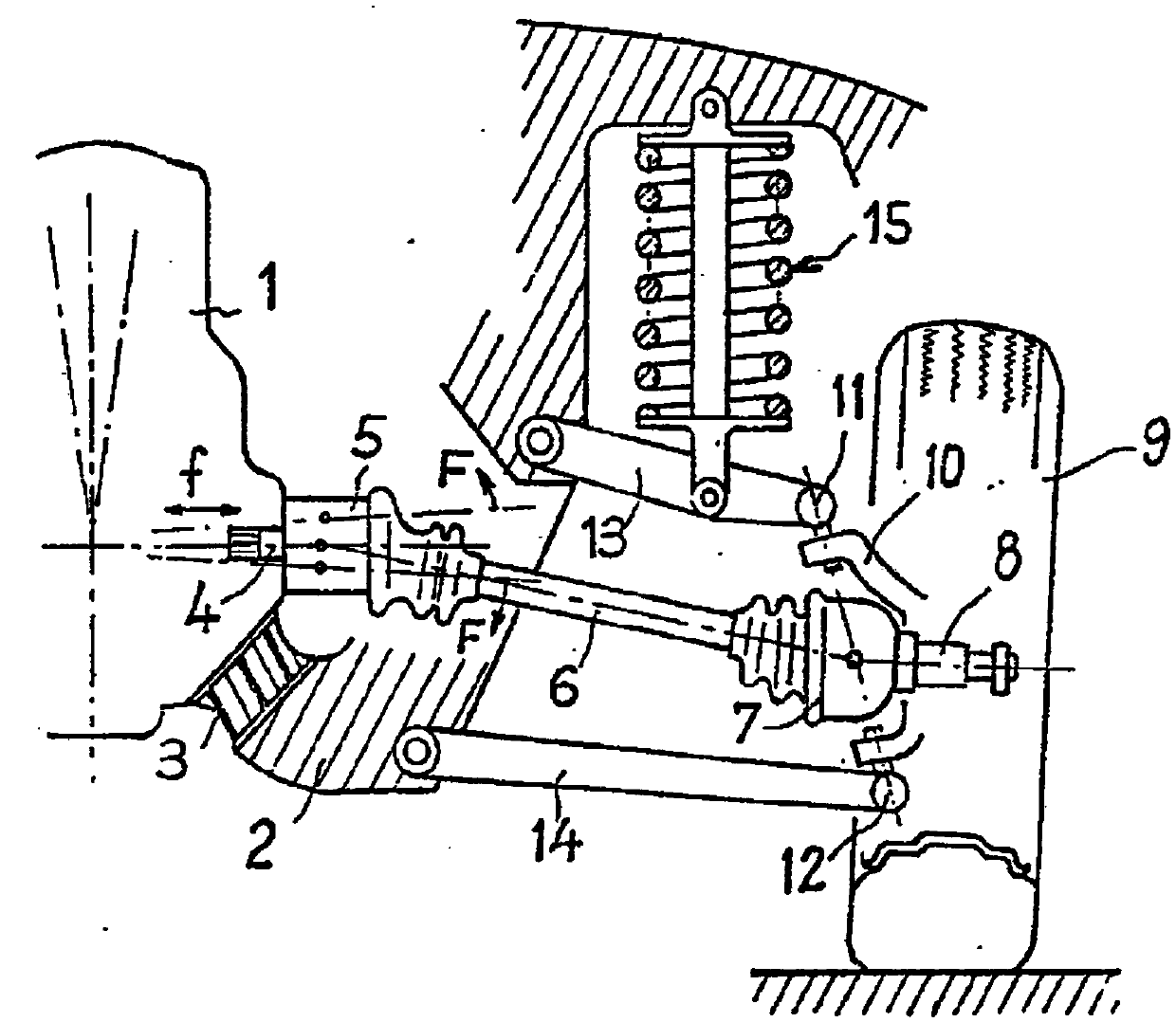

[0060] has been described in conjunction with discussions of the prior art figure 1 , so reference is made at this point to the corresponding expression.

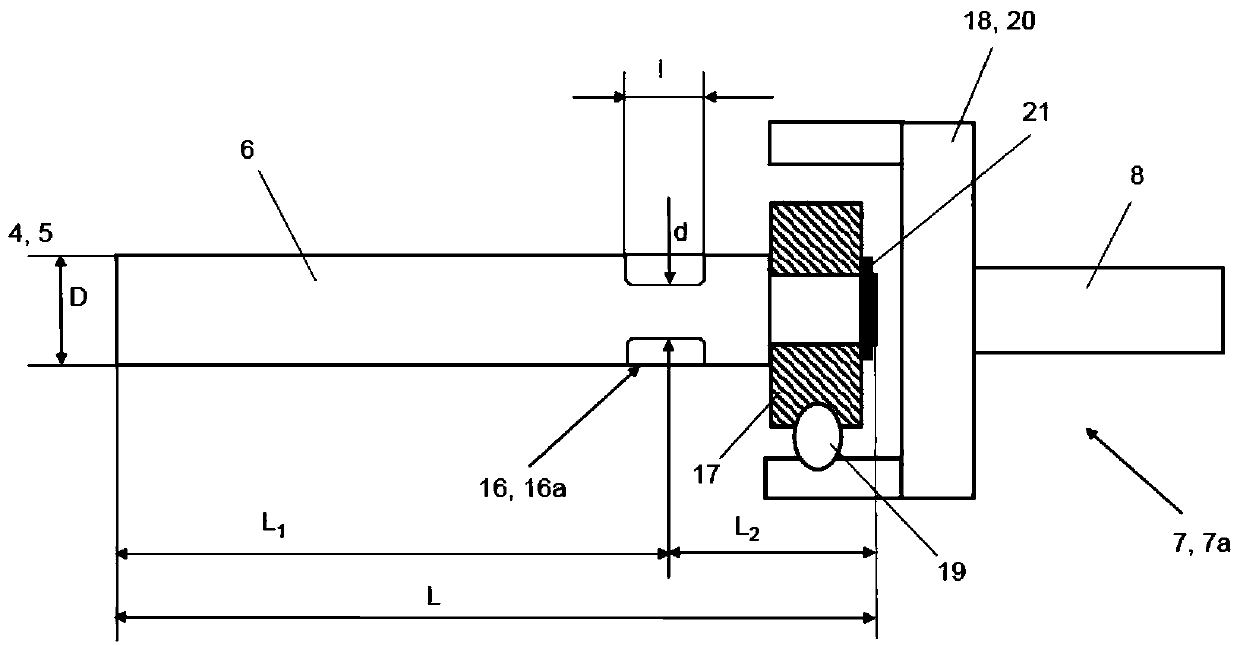

[0061] figure 2 A first embodiment of a transverse drive shaft 6 of a drive train together with an outboard constant velocity joint 7 and a shaft head 8 is schematically shown. only to indicate that relative to figure 1 Additional features of , therefore, additionally refer to figure 1 and related descriptions. The same reference names have been used for the same parts.

[0062] In the installed position, the transverse drive shaft 6 is connected to the transmission output shaft 4 of the drive unit via the inboard constant velocity joint 5 and can be set in rotation via the transmission output shaft 4 .

[0063] The drive shaft 6 is connected via an outboard constant velocity joint 7 to a steerable wheel, which is received by an axle head 8 .

[0064] In the present case, the outer constant velocity joint 7 is a cage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com