A Vibration Damping Device for Underground Petroleum Pipeline Joints

A vibration damping device, oil pipeline technology, applied in the direction of shock absorber, pipe/pipe joint/pipe fitting, pipe element, etc., can solve the problem of easy transmission of vibration load, and achieve the effect of absorbing kinetic energy, facilitating installation and fixing, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

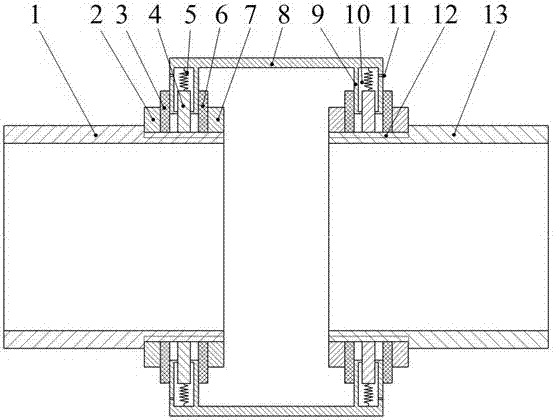

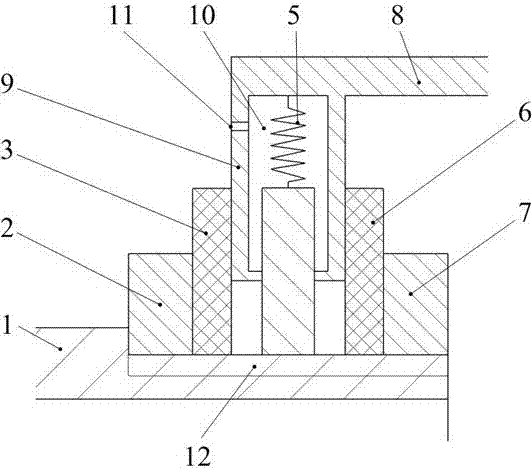

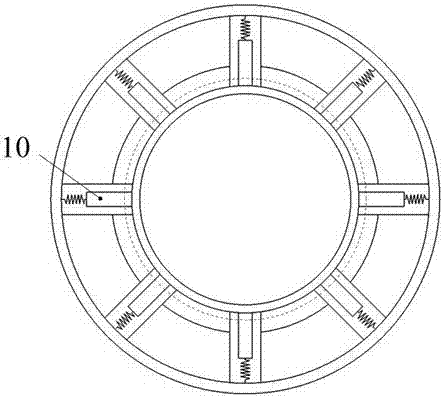

[0018] like figure 1 As shown, a kind of damping device for underground petroleum pipeline interface of the present invention mainly includes pipeline, lock nut, sealing ring, shock absorber 10 and connecting pipe 8, and pipeline is divided into pipeline A 1 and pipeline B 13, The lock nut is divided into lock nut A 2 and lock nut B 7, and the seal ring is divided into seal ring A 3 and seal ring B 6, lock nut A 2, seal ring A 3, shock absorber 10, seal ring B 6. The lock nut B 7 is sequentially installed on the threaded connection area 12 of the pipe A 1 and the pipe B 13 , and the shock absorber 10 is welded on the connecting pipe 8 . The interface between pipe A and pipe B is provided with external threads, and lock nut A and lock nut B, sealing ring A and sealing ring B are provided with internal threads. This structural design has the following functions: First, it is easy to install and fix, such as It can be installed by simply rotating the sealing ring A 3 on the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com