Transverse driving shaft of power transmission system of motor vehicle including internal combustion engine and transmission

A power transmission system and lateral drive technology, applied in vehicle components, transportation and packaging, control devices, etc., can solve problems such as the impact of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

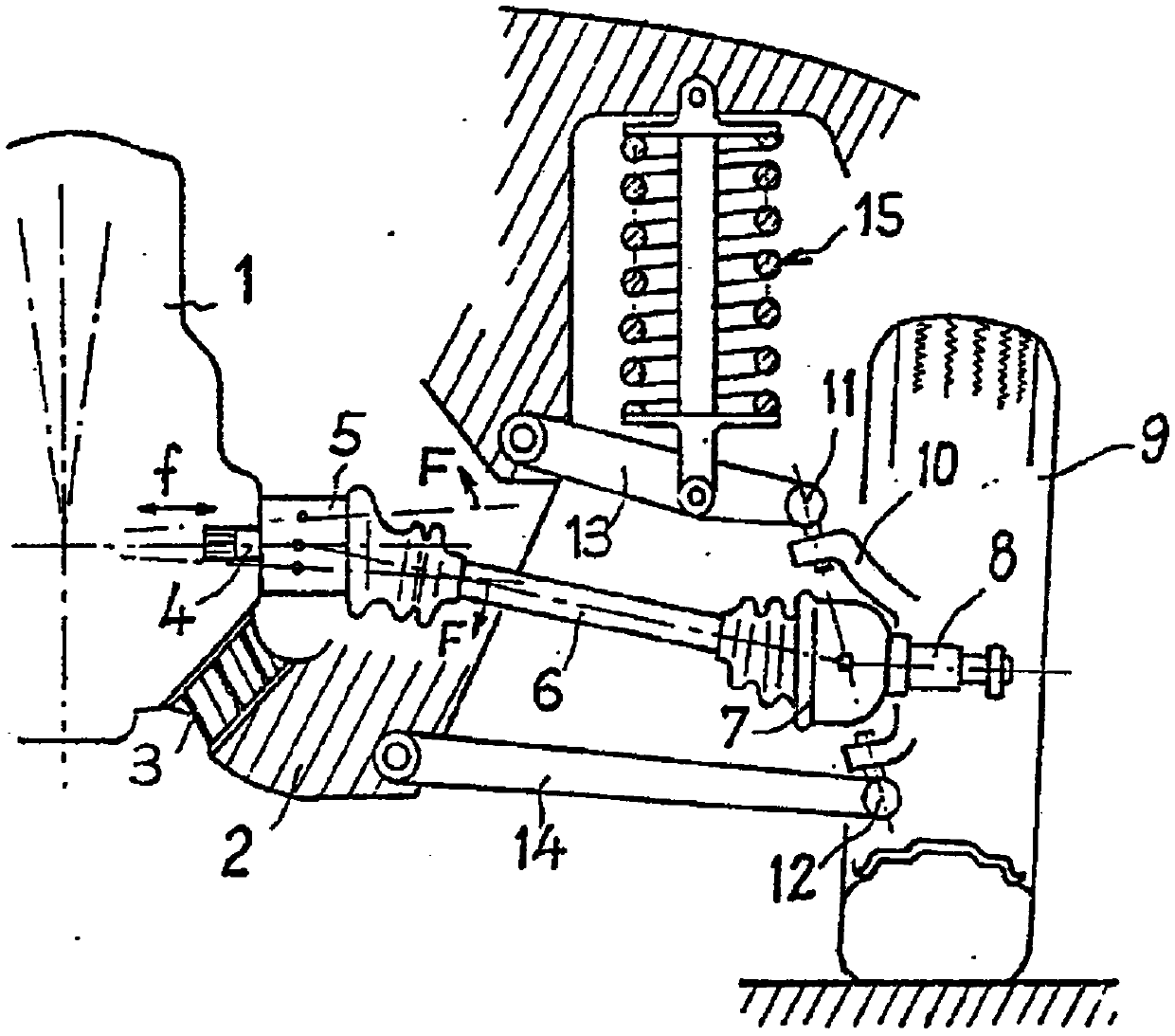

[0053] Has been described in conjunction with the discussion of the existing technology figure 1 , So refer to the corresponding statement at this time.

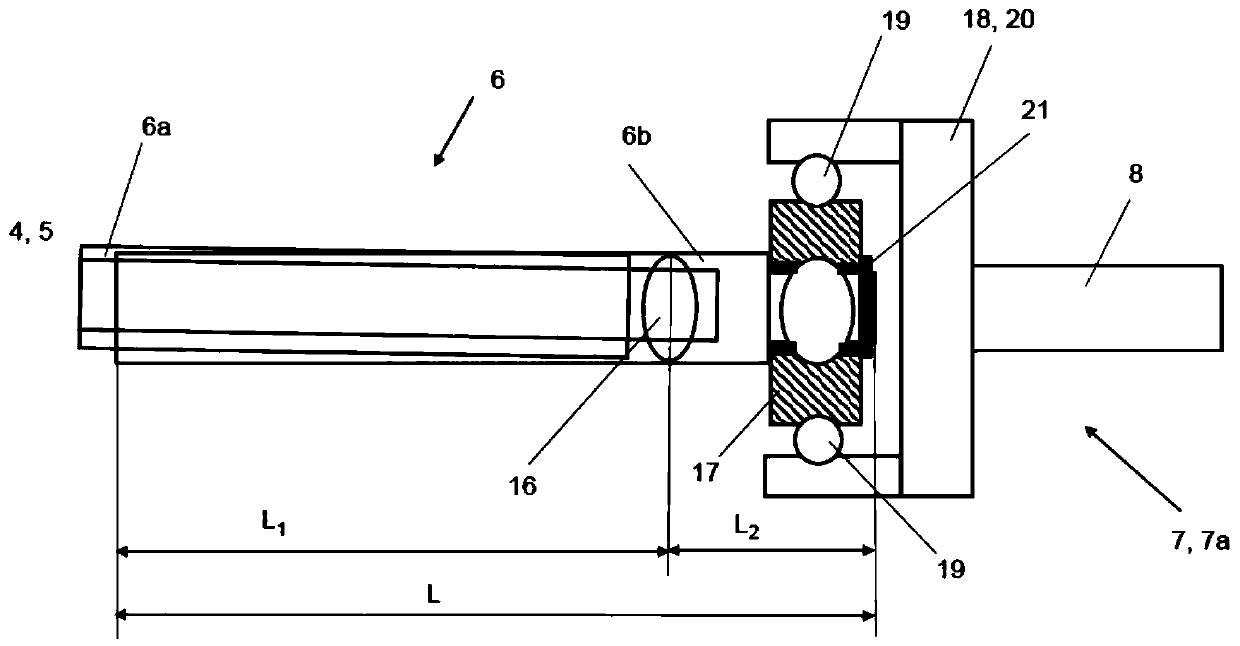

[0054] figure 2 The first embodiment of the transverse drive shaft 6 of the power transmission system together with the outer constant velocity universal joint 7 and the shaft head 8 is schematically shown. Only stated relative to figure 1 Additional features, therefore, additionally refer to figure 1 And related description. The same reference name has been used for the same part.

[0055] In the installation position, the transverse drive shaft 6 is connected to the transmission output shaft 4 of the drive unit through the inner constant velocity universal joint 5 and can be set to rotate through the transmission output shaft 4.

[0056] The drive shaft 6 is connected to a steerable wheel via an outer constant velocity universal joint 7 which is received by the axle head 8.

[0057] In the current situation, the outer constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com