Collapsible reel mechanism

A technology of expansion and contraction reel and expansion and contraction, which is applied in the field of steel strip uncoiler equipment, can solve the problems of low sensitivity of mechanism action, influence on the effect of expansion and contraction uncoiling, insufficient stretching force, etc. production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

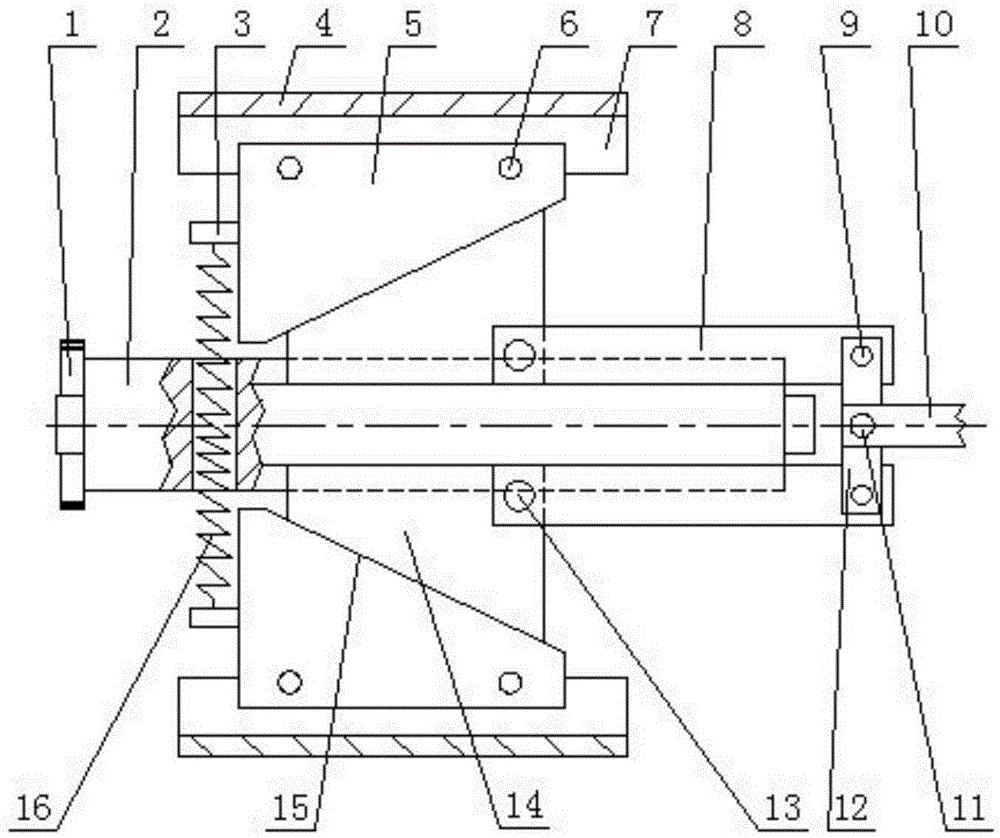

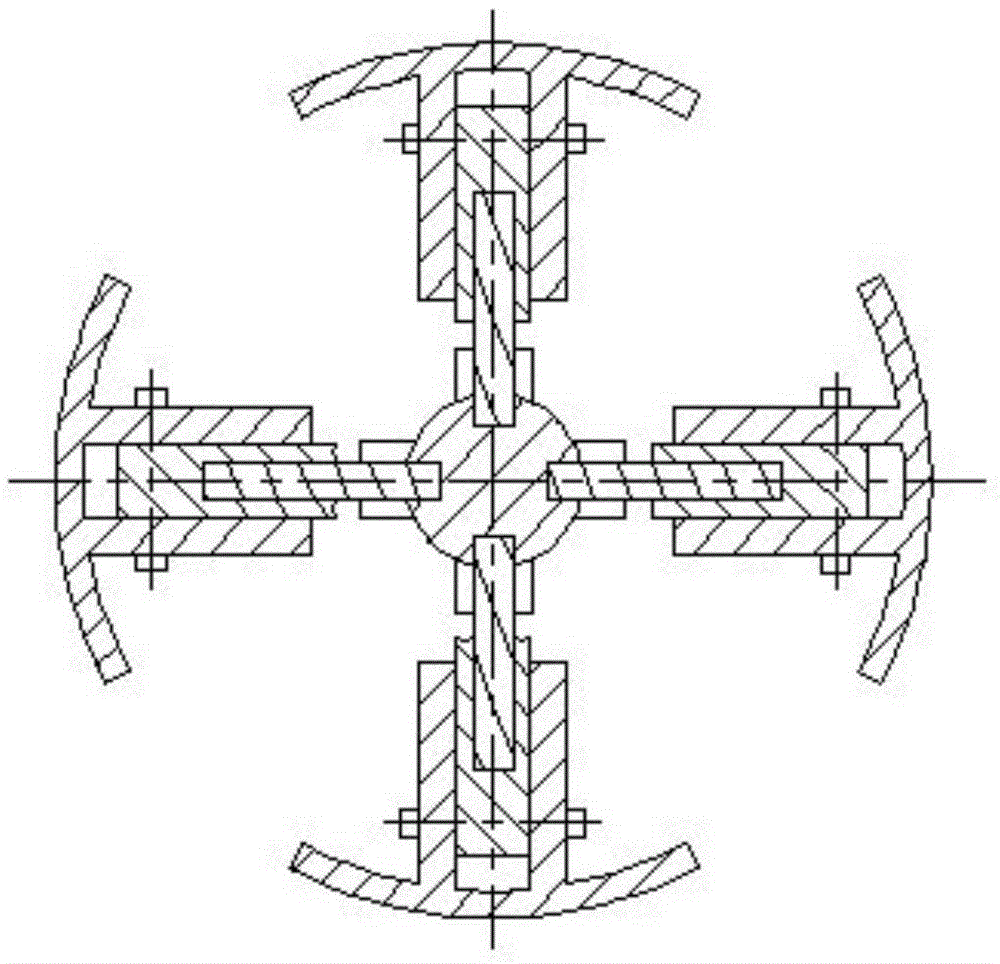

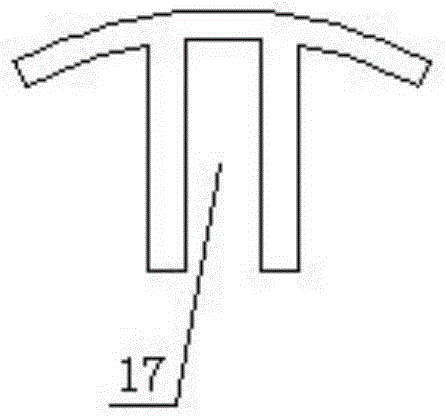

[0013] A kind of expansion and contraction reel mechanism, see attached Figure 1-Figure 4 , which is characterized in that: it includes a main shaft 2, an expansion and contraction reel 4, a spring device 16 and an expansion and contraction transmission mechanism; there are at least three slide grooves 18 on the outer circumference of the main shaft; the expansion and contraction reel 4 is composed of at least three It is composed of two separate reels that are independent of each other, and are set on the outside of the main shaft 2. Each reel has the same central angle and radius, and the inner side of the reel is provided with a connecting seat 7, and each reel can expand with each other. The shrinking block 5 moves radially; the expansion and contraction transmission mechanism includes an expansion and contraction power device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com