Hot upsetting die and upper die thereof

A mold and hot upsetting technology, applied in the field of hot upsetting molds and their upper molds, can solve problems affecting normal demoulding, etc., achieve the effects of reducing spring costs, improving stamping accuracy, and avoiding shaking or misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

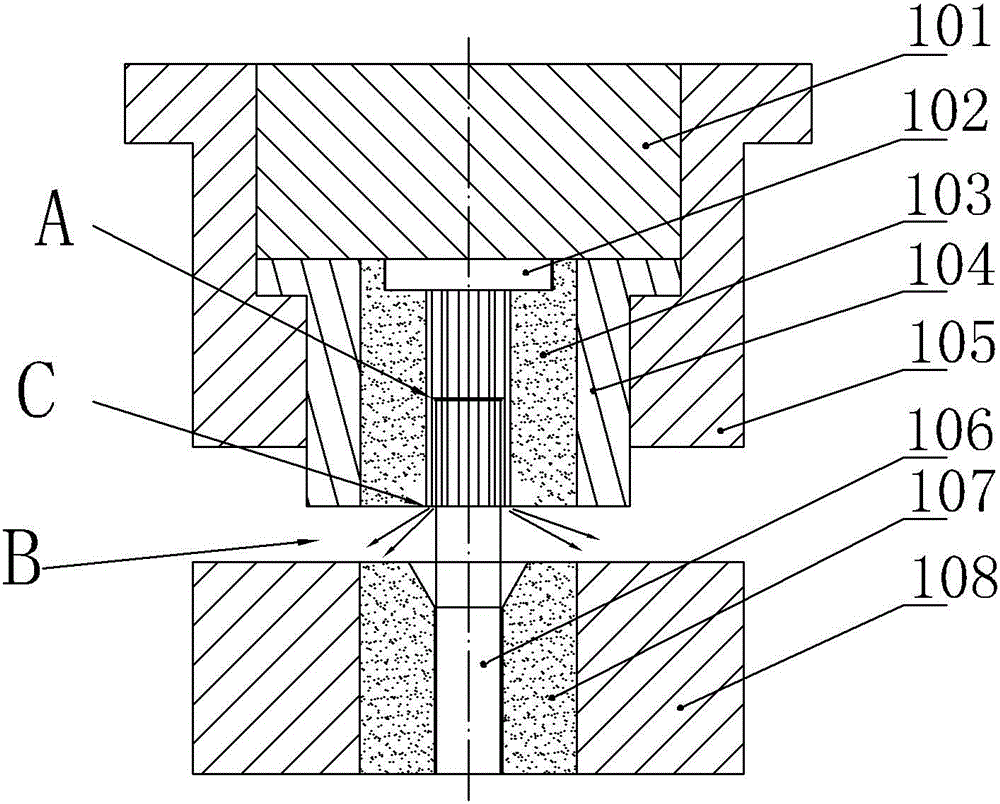

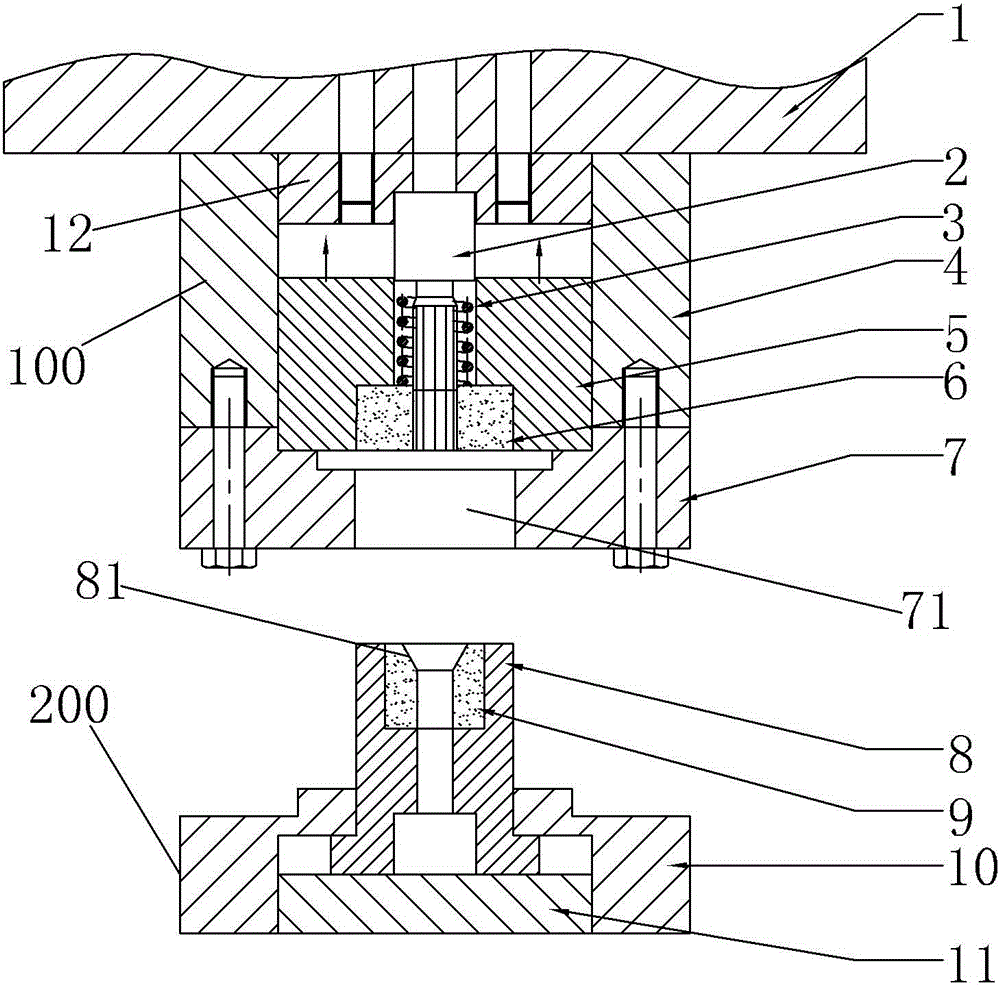

[0026] Such as image 3 , Figure 4 Shown is an embodiment of a hot upsetting mold in which the upper and lower molds are formed simultaneously. The hot upsetting mold in this embodiment includes an upper mold 100 and a lower mold 200 for connecting up and down.

[0027]Lower mold 200 comprises lower mold base 11, lower mold core assembly and lower mold cover 10, and lower mold core assembly is fixedly assembled on the lower mold base 11 by lower mold cover 10, and lower mold core assembly here comprises lower mold core 9 and lower mold cover 10. The mold core cover 8 is correspondingly provided with a perforation for the upper end of the lower mold core assembly to pass upwards on the lower mold cover 10. The upper end surface of the lower mold core 9 is flush with the upper end surface of the lower mold core cover 8. A lower forming groove 81 is arranged on the upper end surface, and the lower forming groove 81 is correspondingly arranged at the upper end opening position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com