Clamping device for easily detachable spindle base

A technology of clamping device and sub-spindle, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of waste, high labor intensity, low production efficiency, etc., and achieve the effect of reducing production costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

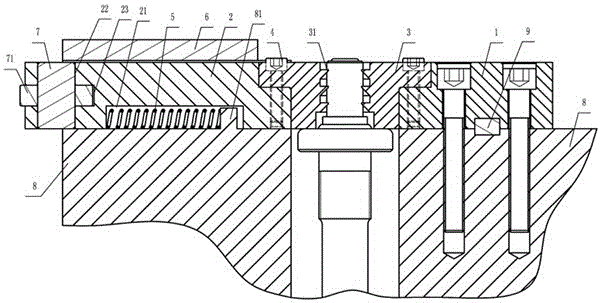

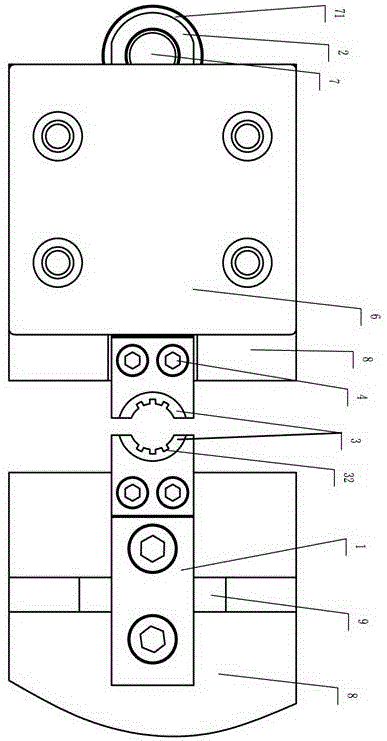

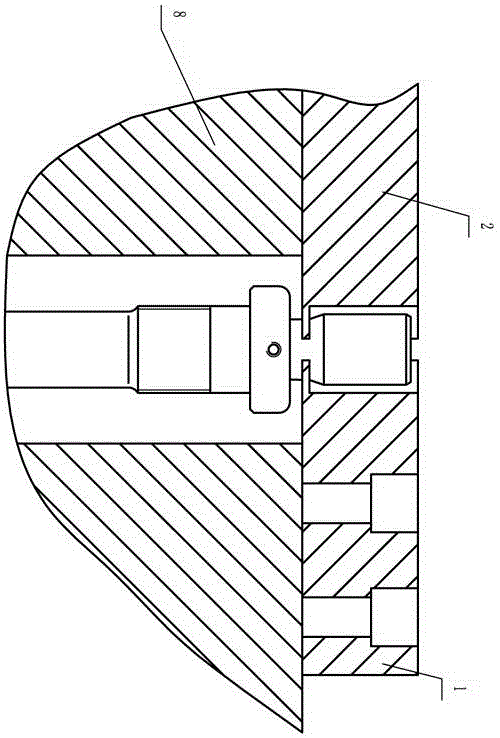

[0033] Such as figure 1 , figure 2 As shown, a clamping device for an easy-to-split spindle base, which includes a right base 1, a left base 2 and a jacket, the right base 1 and the left base 2 are rectangular parallelepiped and symmetrically arranged, and the right base 1 is fixed on the base of the press 8; the jacket includes two symmetrically arranged semi-circular jacket blocks 3, the jacket blocks 3 are symmetrically fixed on the right base 1 and the left base 2 respectively by bolts 4, when the two jacket blocks 3 are closed, it forms The inner hole of the inner hole can clamp the bearing seat of the ingot liner. The inner surface of the jacket block 3 is axially provided with three radial ring teeth 31 with a trapezoidal cross section. The front end of the trapezoidal teeth is thin and the rear end is thick, so that the ring teeth can bite into On the outer circle of the bearing housing, the radial annular teeth 31 are provided with axial grooves 32 to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com