Plastic profile extrusion die head allowing material flow speed at single arm parts to be adjusted

A technology for extrusion dies and profiled materials, which is applied in the field of extrusion dies for plastic profiled materials, which can solve problems such as uneven discharge and unqualified single-arm molding, so as to prolong the service life, prolong the production cycle, and realize speed control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

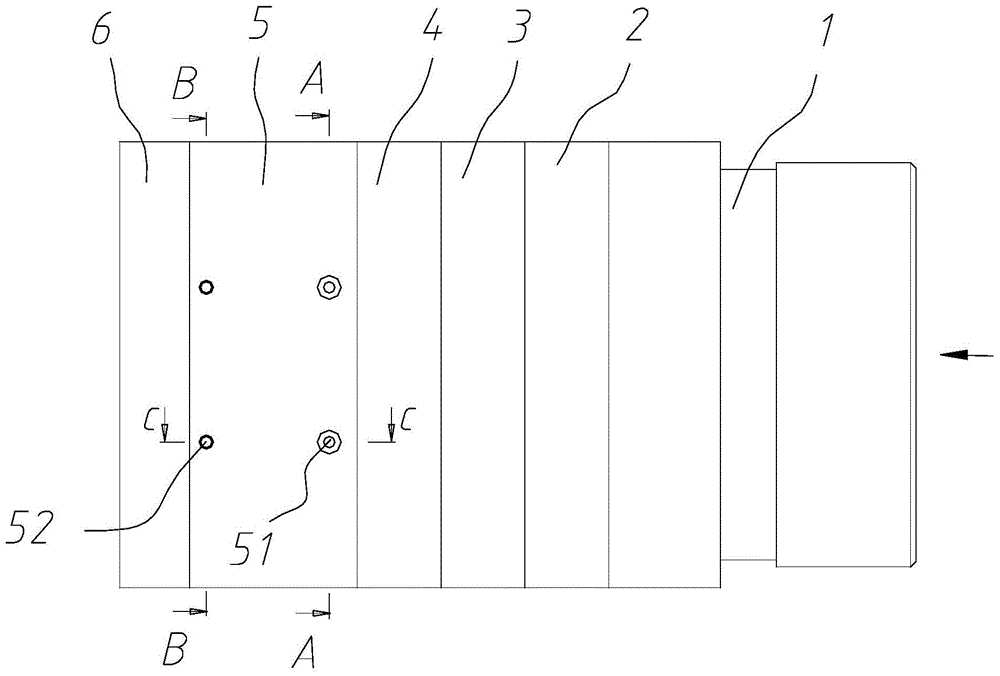

[0026] Such as figure 1 As shown, the extrusion die head of the present invention includes a machine neck 1, a support plate 2, a support plate 2 3, a compression plate 4, a preformed plate 5 and a forming plate 6, and a core 7 is fixed on the support plate 2 3.

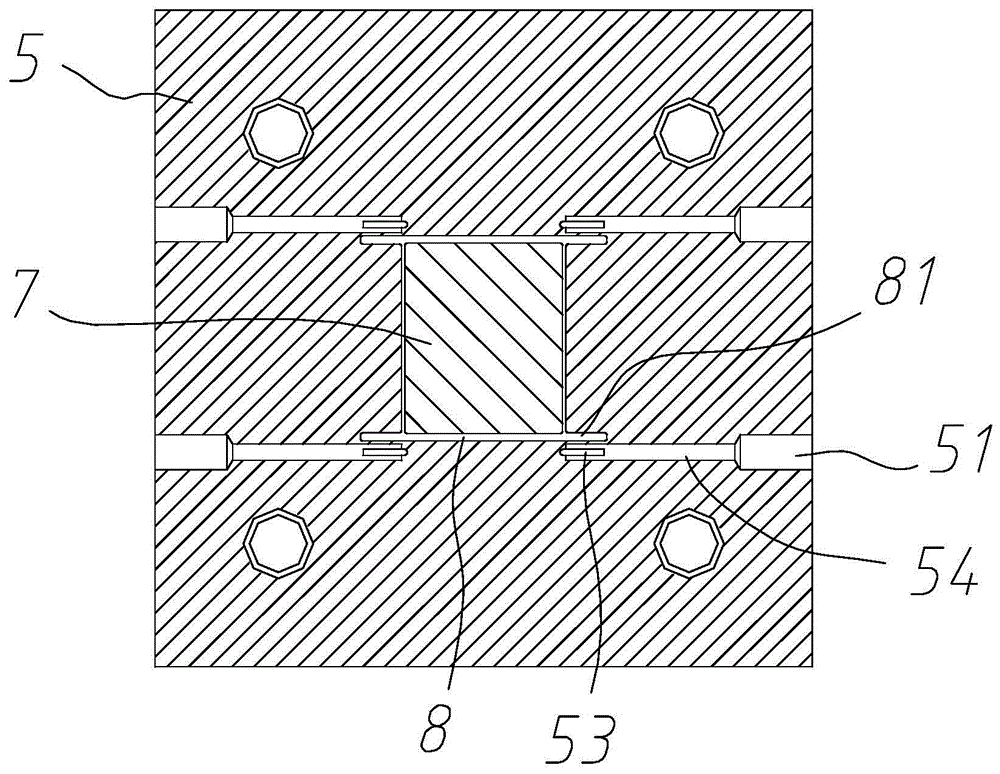

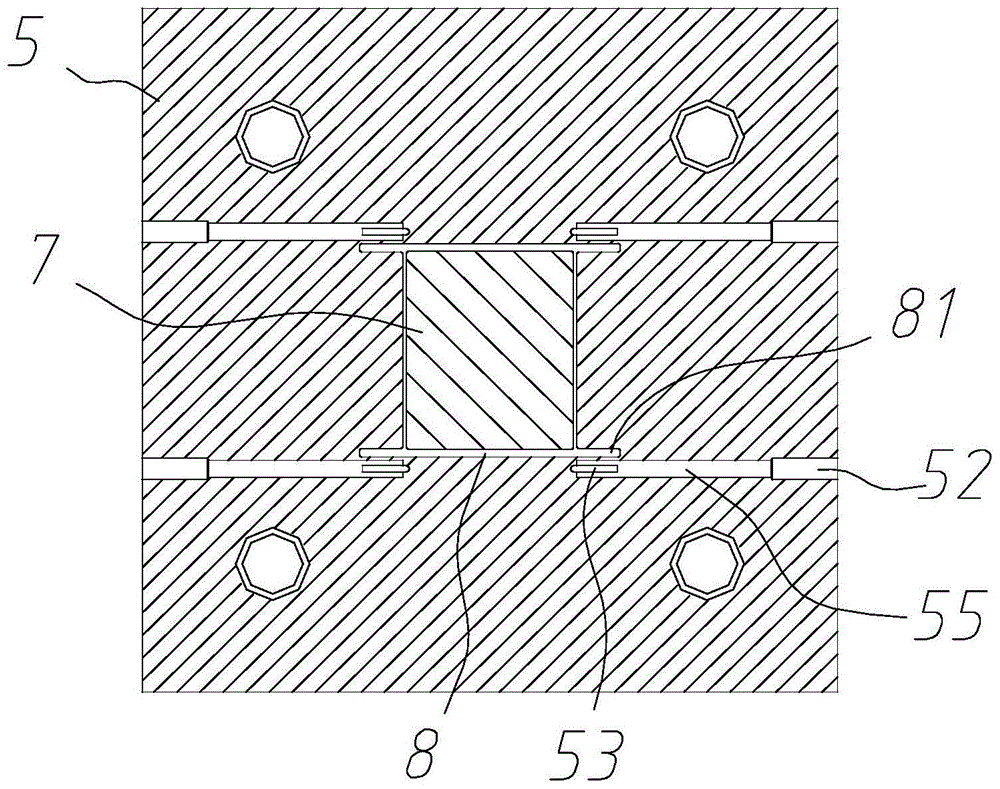

[0027] Such as Figure 2 to Figure 4 As shown, the gap between the preformed plate 5 and the core 7 in the middle is the cavity 8 , and the four corners of the cavity 8 have protruding parts extending outwards which are single-arm parts 81 of the cavity. The preformed plate 5 is provided with an air flow channel 53 distributed along the flow direction of the parison inside the cavity wall corresponding to the single arm portion 81 of each cavity. The intake and exhaust ports 51, 52 and the intake and exhaust channels 54, 55 are distributed sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com