Patents

Literature

30results about How to "Consistent output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moon cake stuffing machine

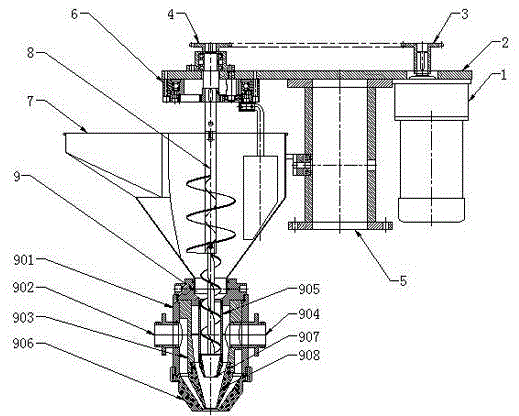

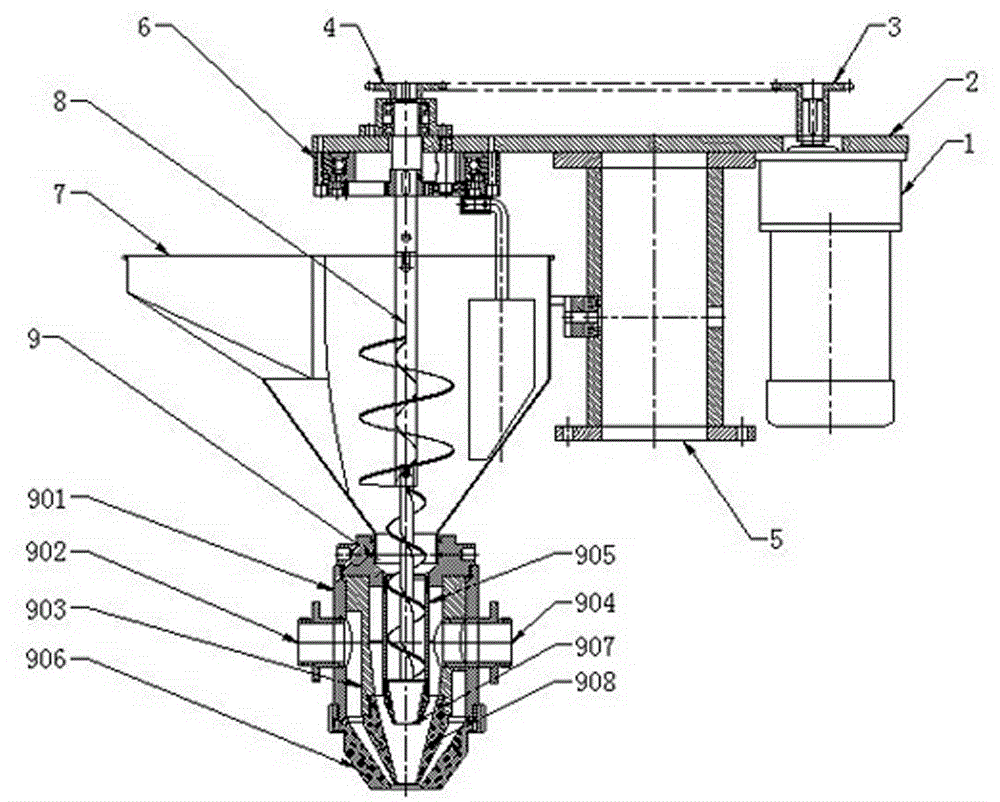

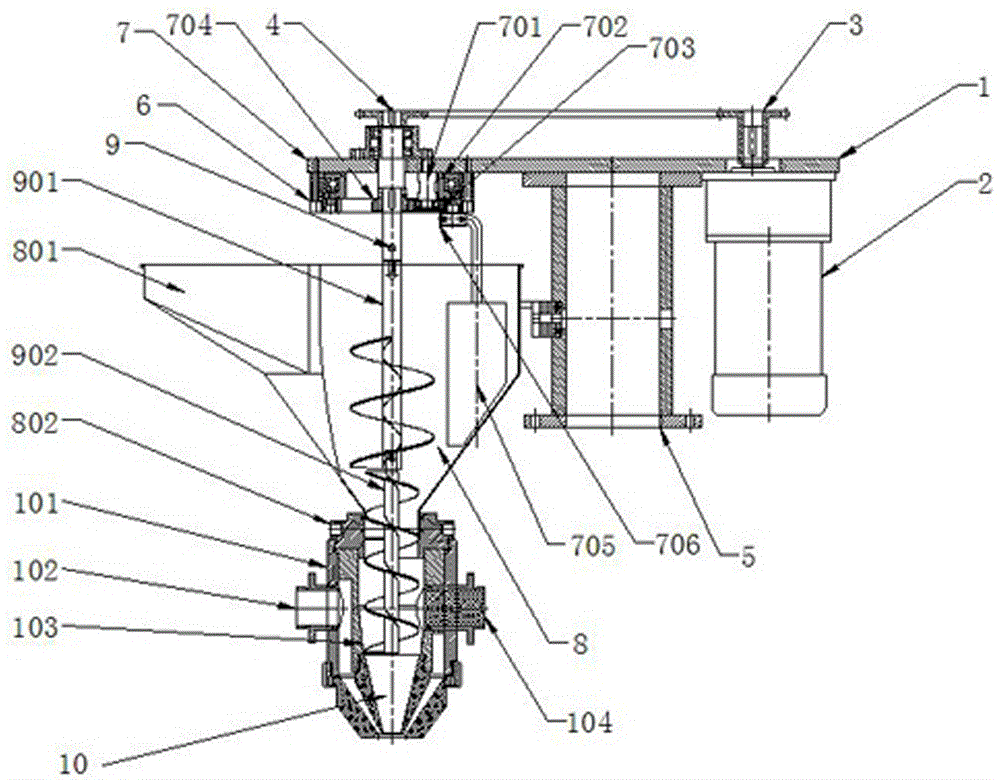

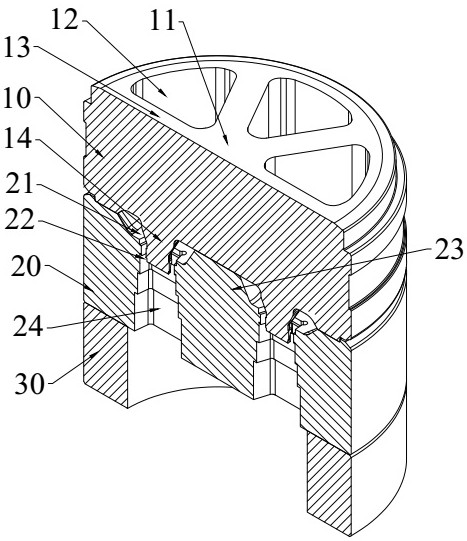

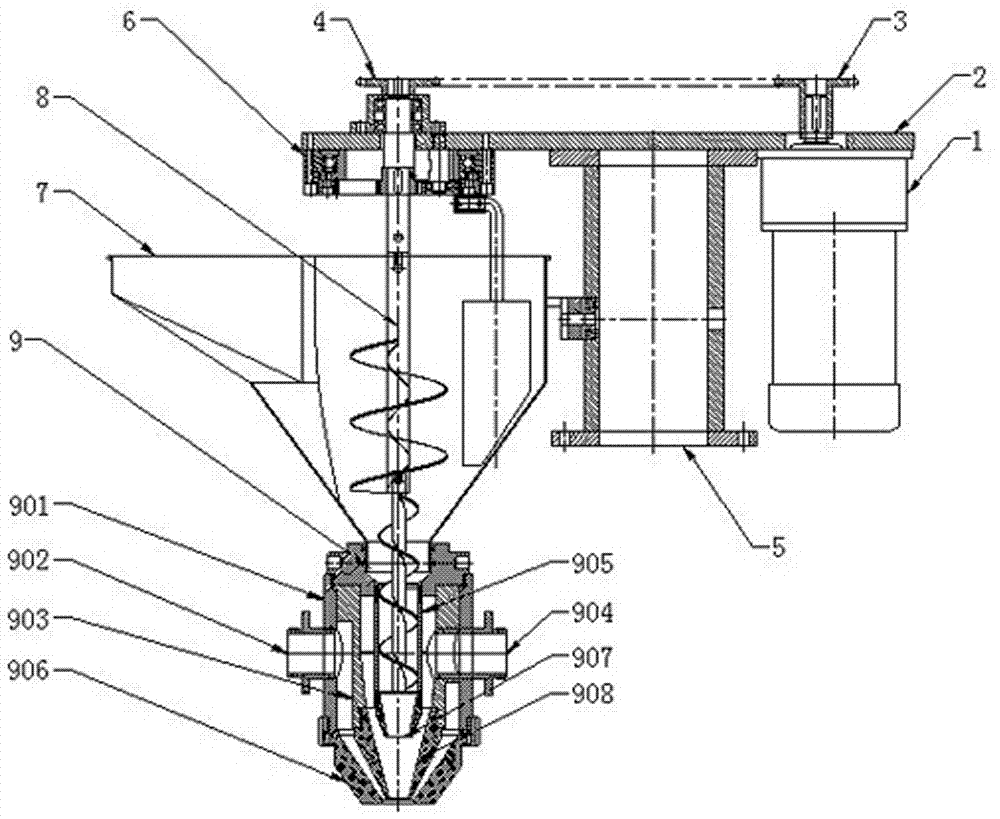

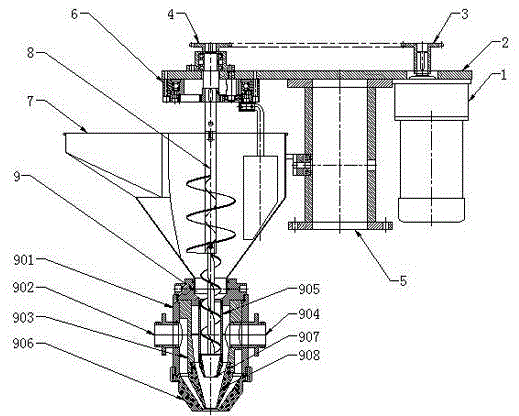

The invention discloses a moon cake stuffing machine and relates to the field of food processing machinery. The moon cake stuffing machine is characterized by comprising a motor, a support plate, a driving chain wheel, a driven chain wheel, a support seat, an inner gear bearing block, a material stirring assembly, a hopper assembly, a packing auger assembly and a wrapper / stuffing assembly, wherein the motor is arranged below one end of the support plate; the driving chain wheel is arranged above one end of the support plate; the support seat is arranged below the middle part of the support plate; the inner gear bearing block is arranged below the other end of the support plate; the material stirring assembly is arranged above the inner gear bearing block; the driven chain wheel is arranged above the material stirring assembly; the hopper assembly and the packing auger assembly are arranged below the inner gear bearing block; and the wrapper / stuffing assembly is arranged below the packing auger assembly. According to the moon cake stuffing machine, stuffing with five kernels can be evenly injected into a moon cake wrapper; the conditions of moon cake stuffing blockage, discontinuously feeding and a great error in the moon cake size are not generated; the stuffing with five kernels is injected into the wrapper from top to bottom; and the condition of turning of the stuffing is avoided.

Owner:合肥市开平食品贸易有限责任公司

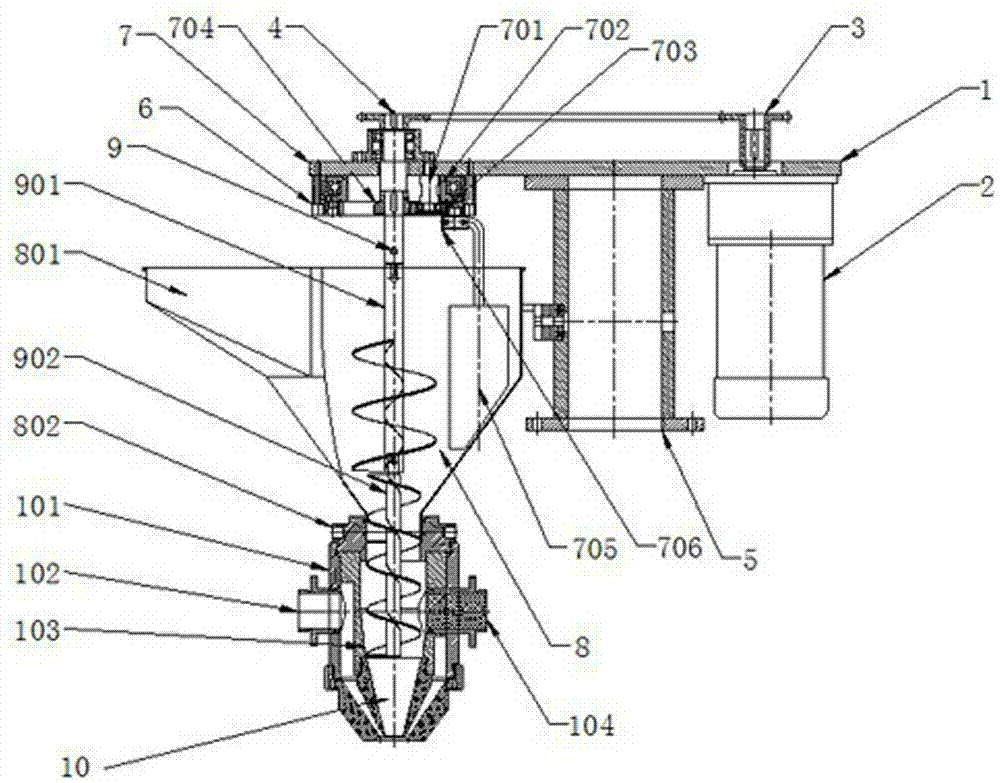

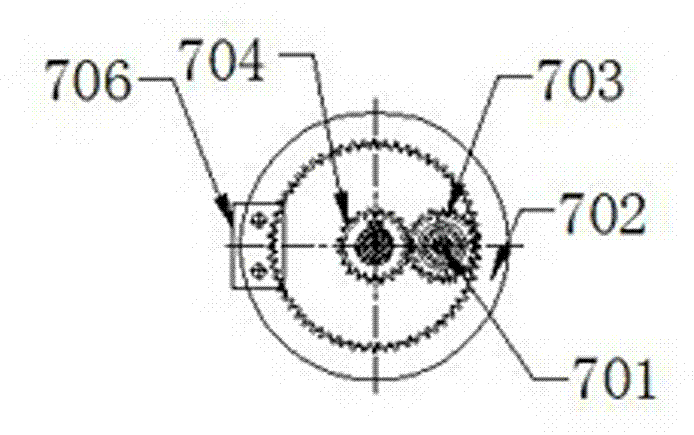

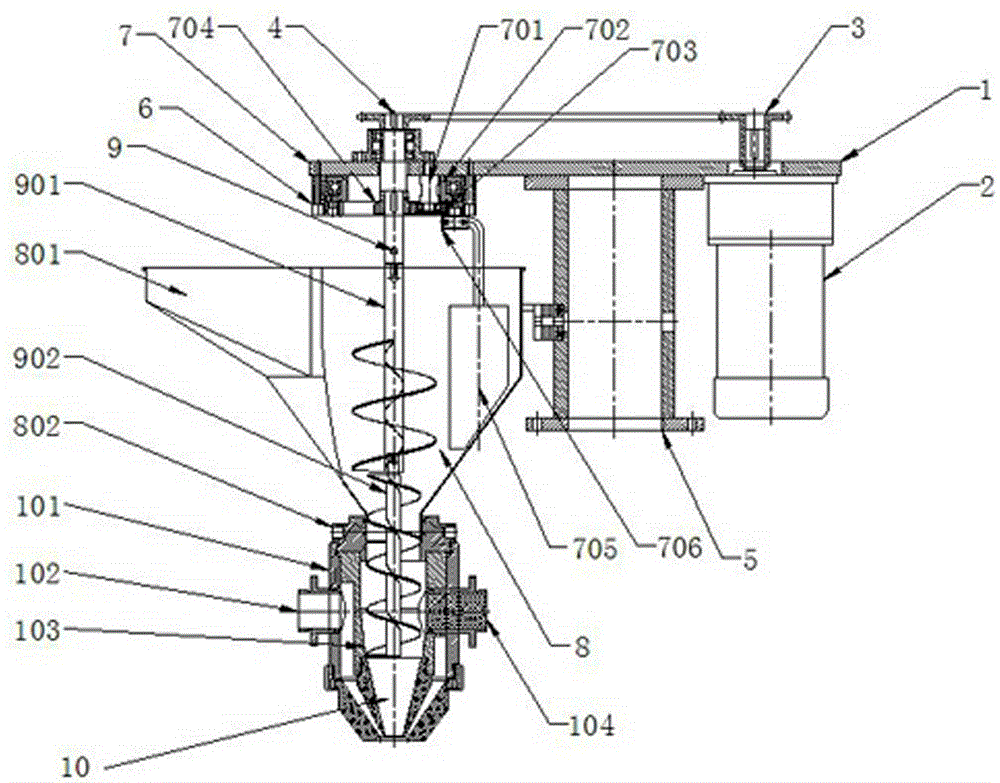

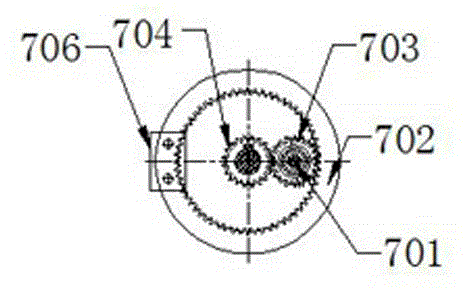

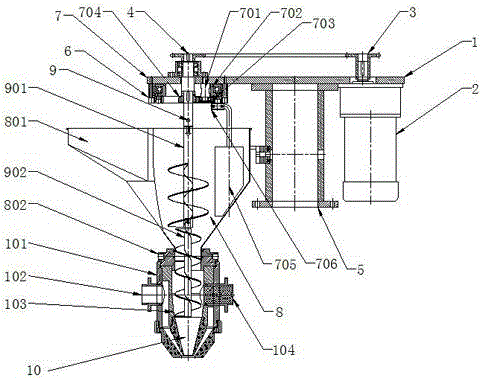

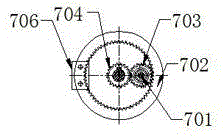

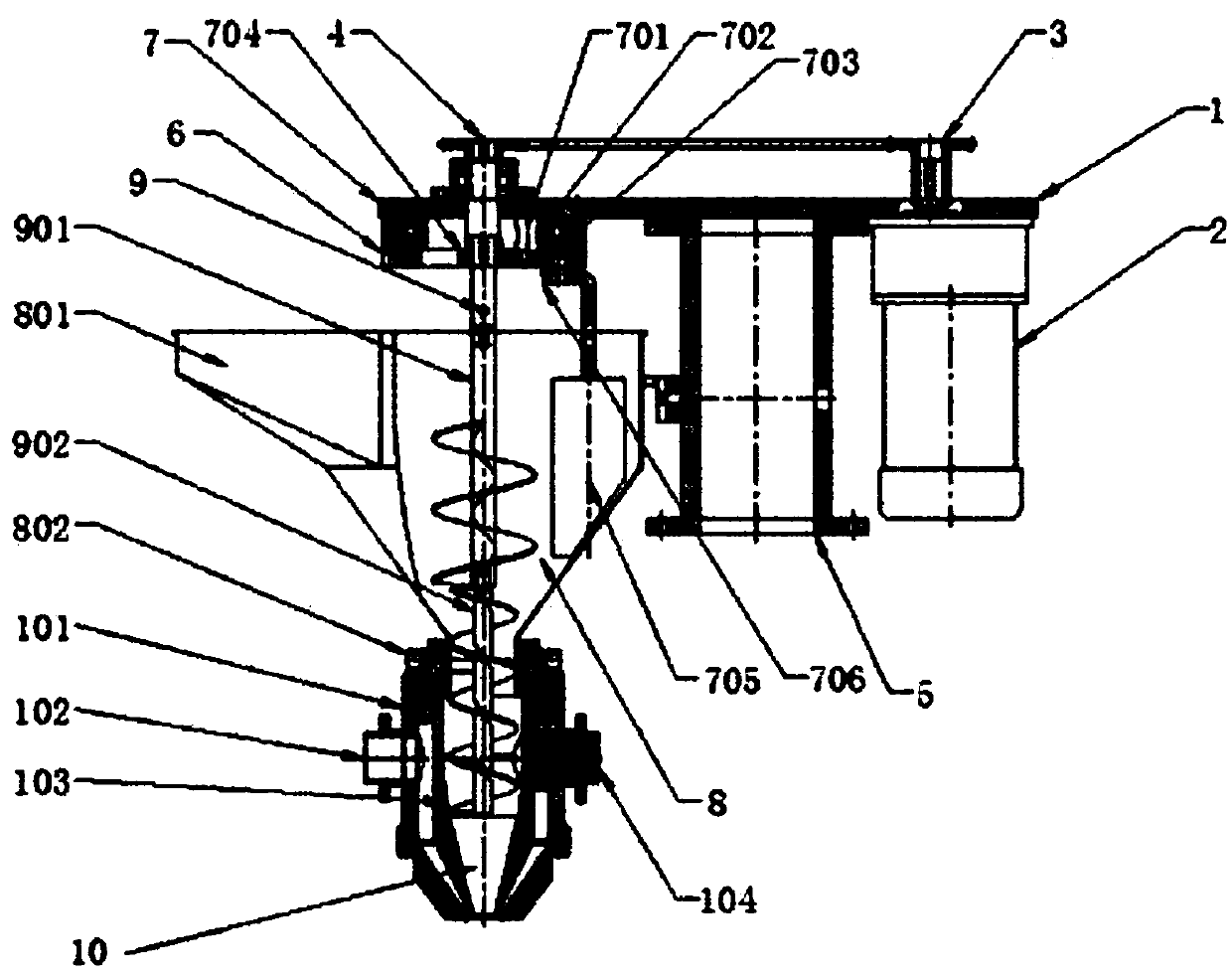

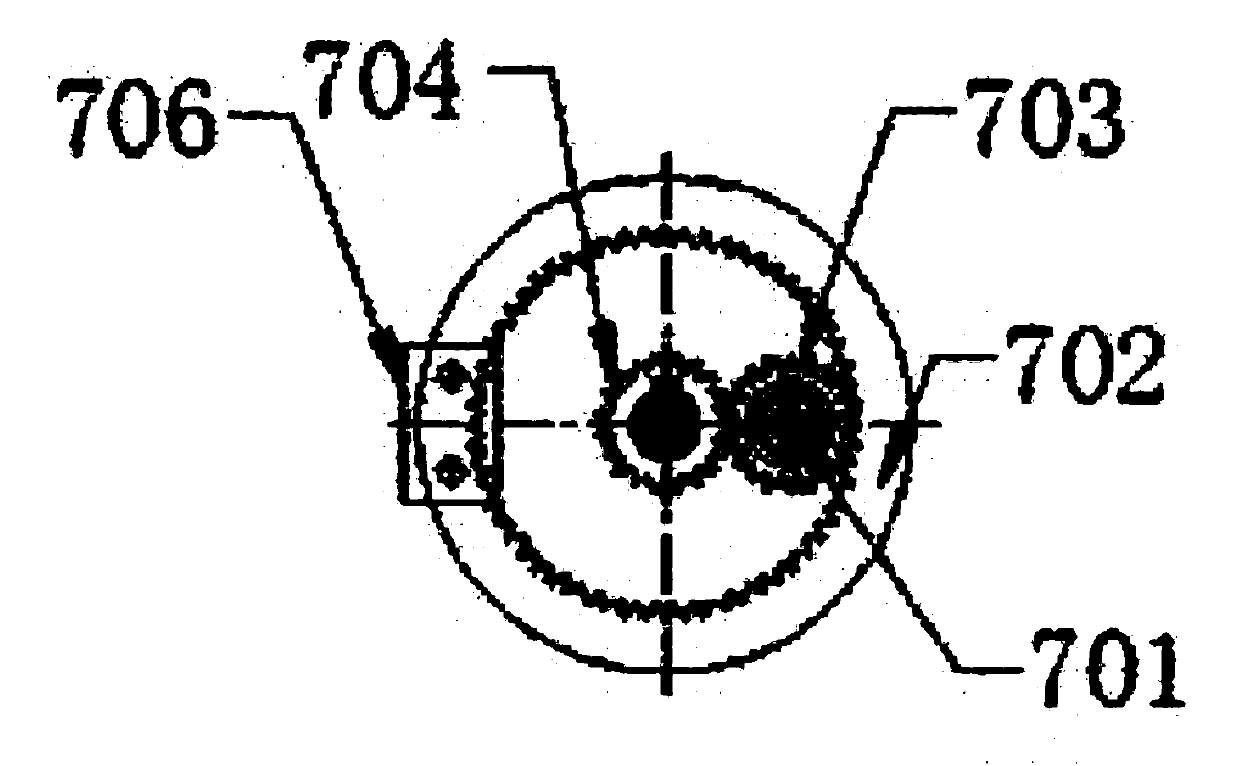

Automatic encrusting device

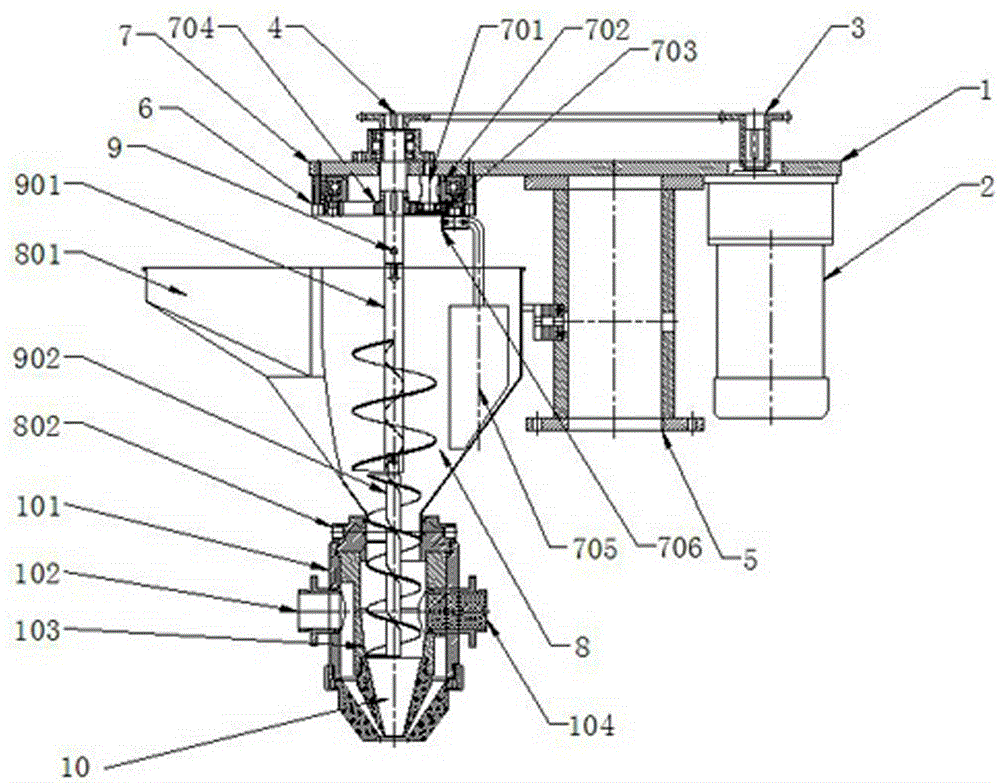

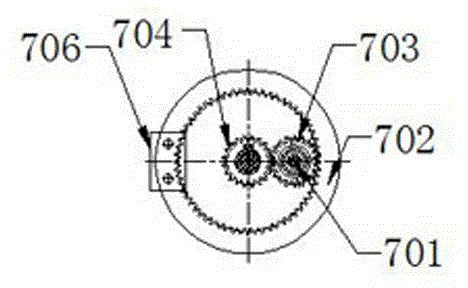

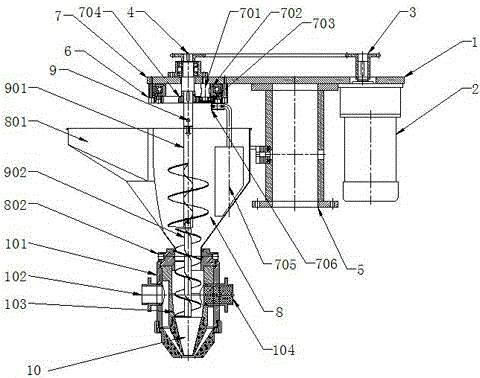

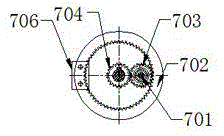

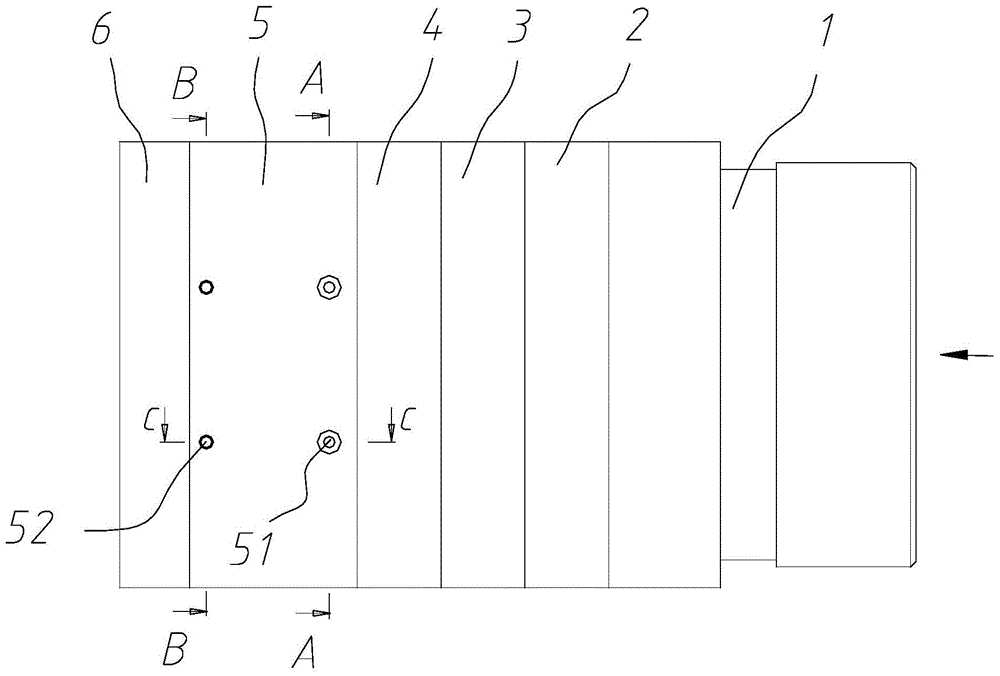

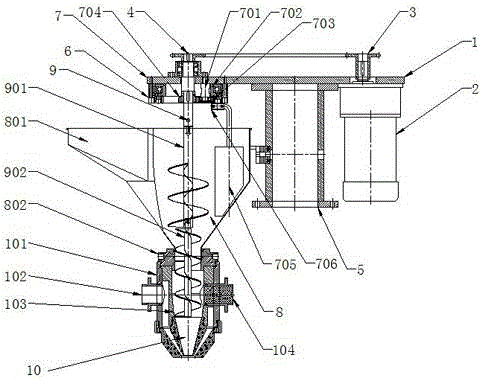

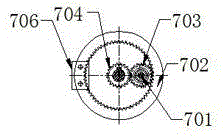

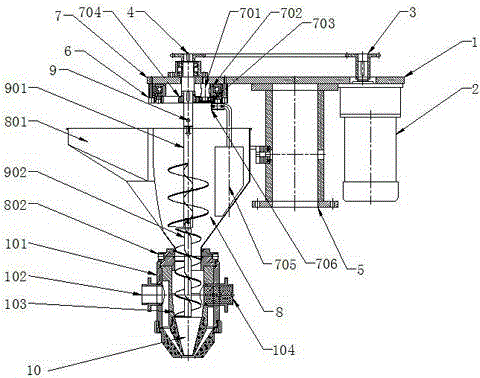

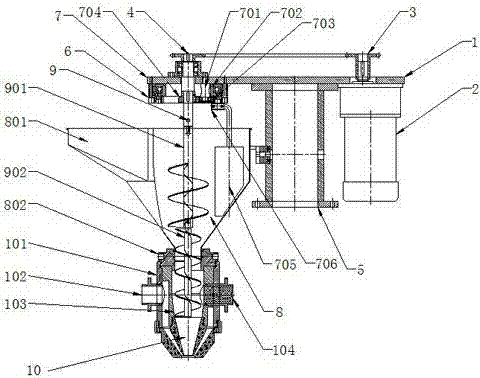

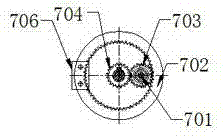

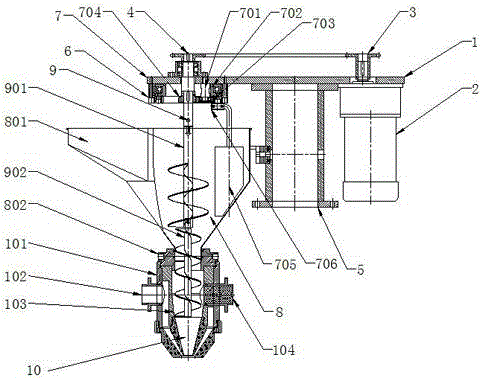

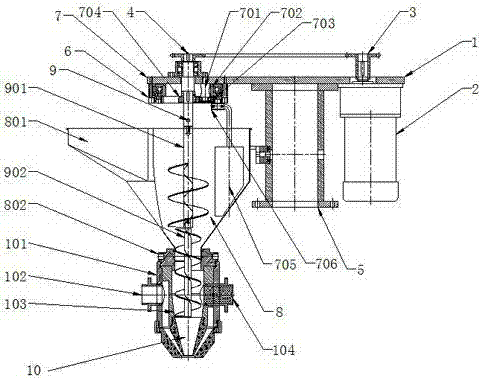

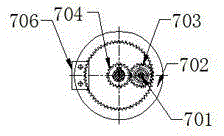

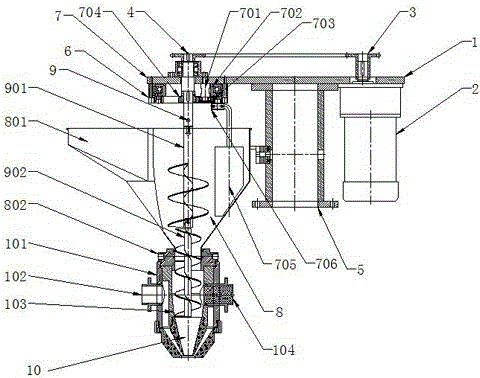

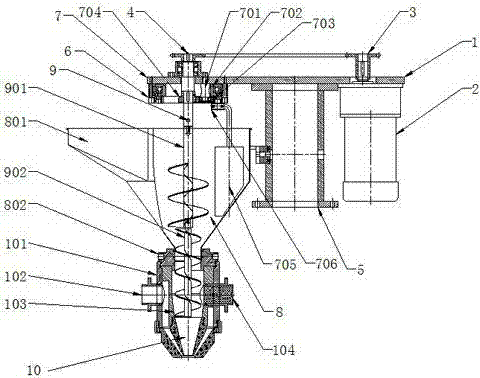

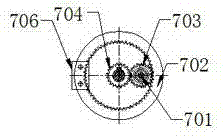

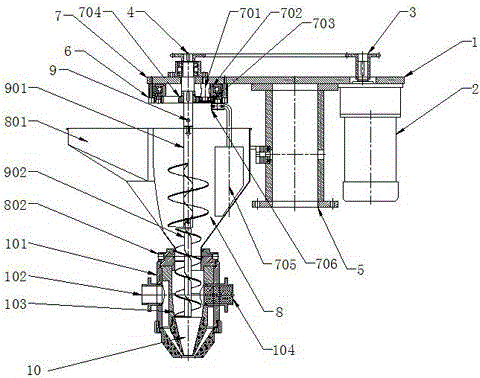

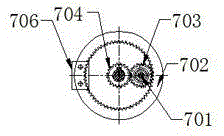

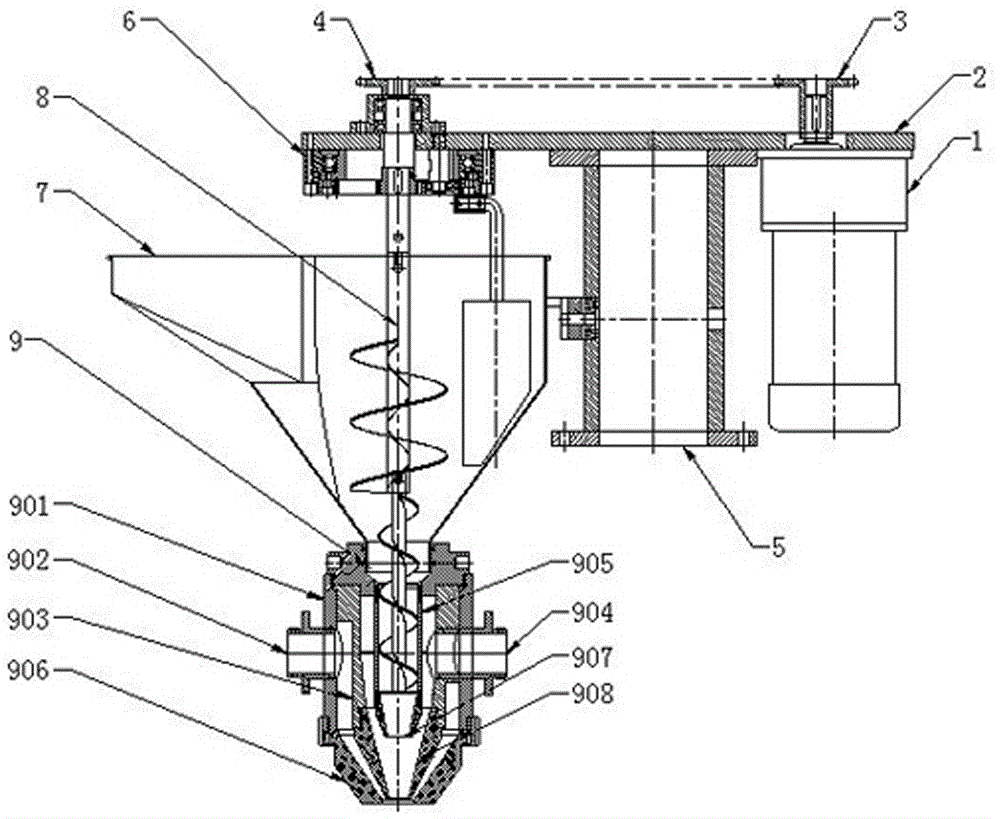

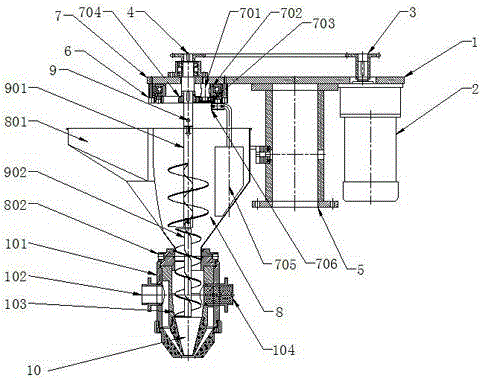

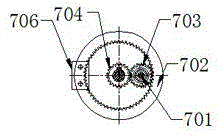

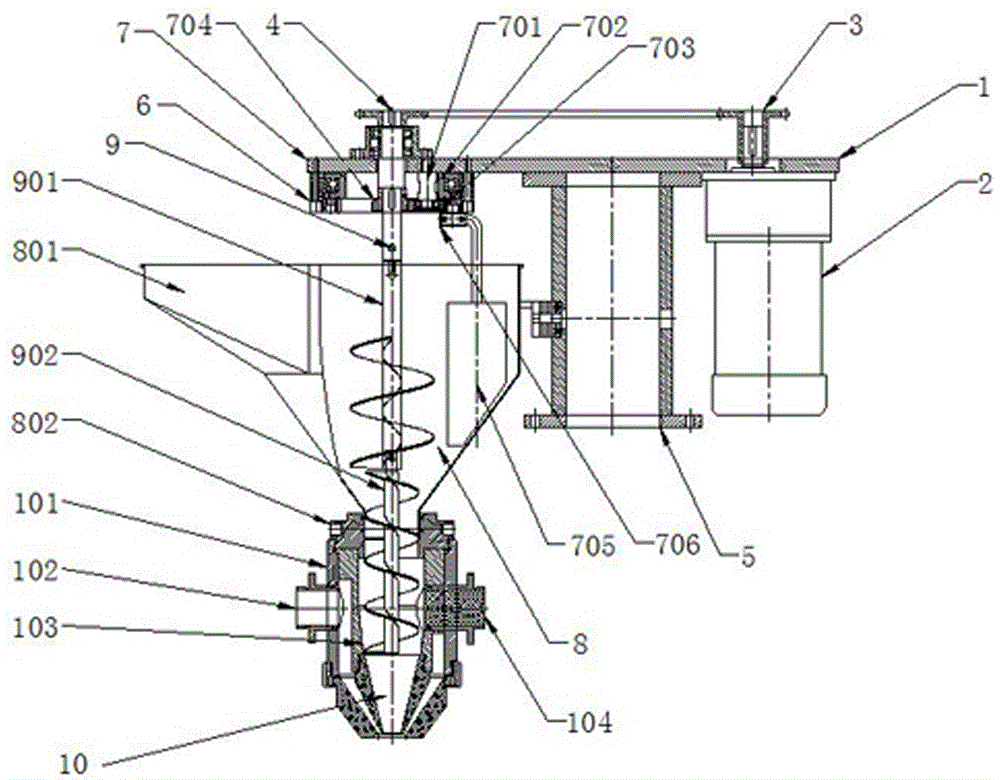

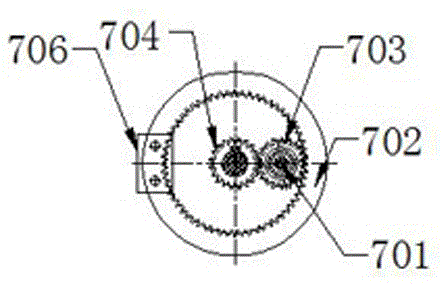

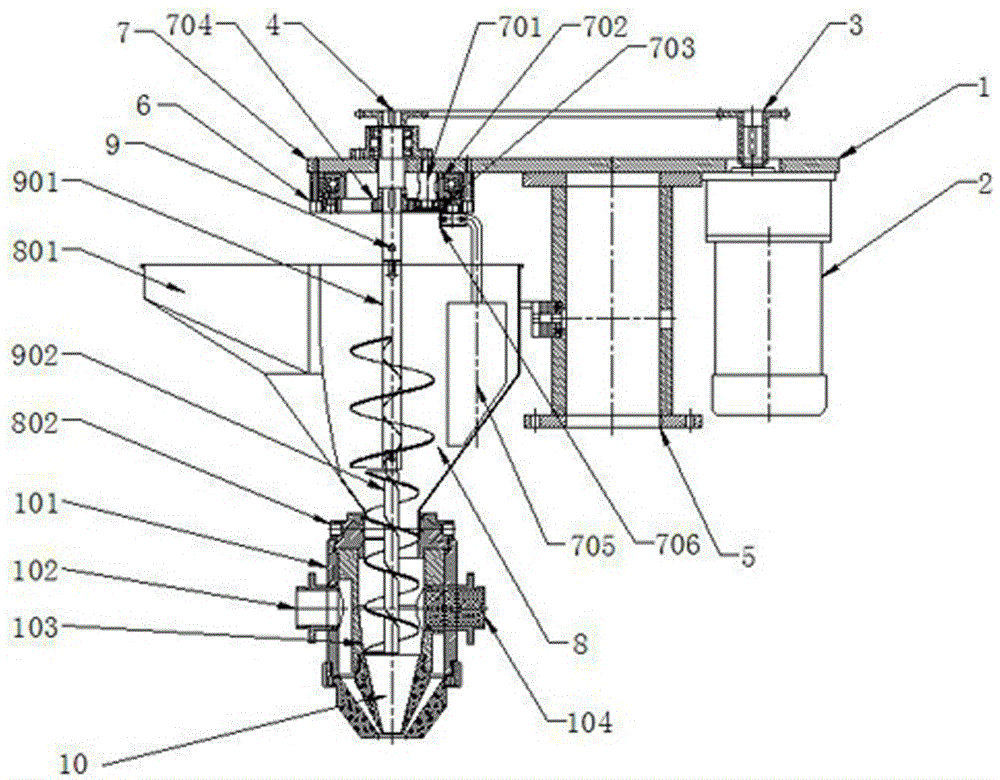

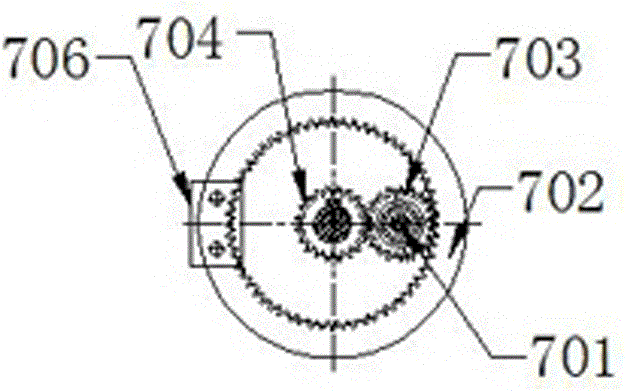

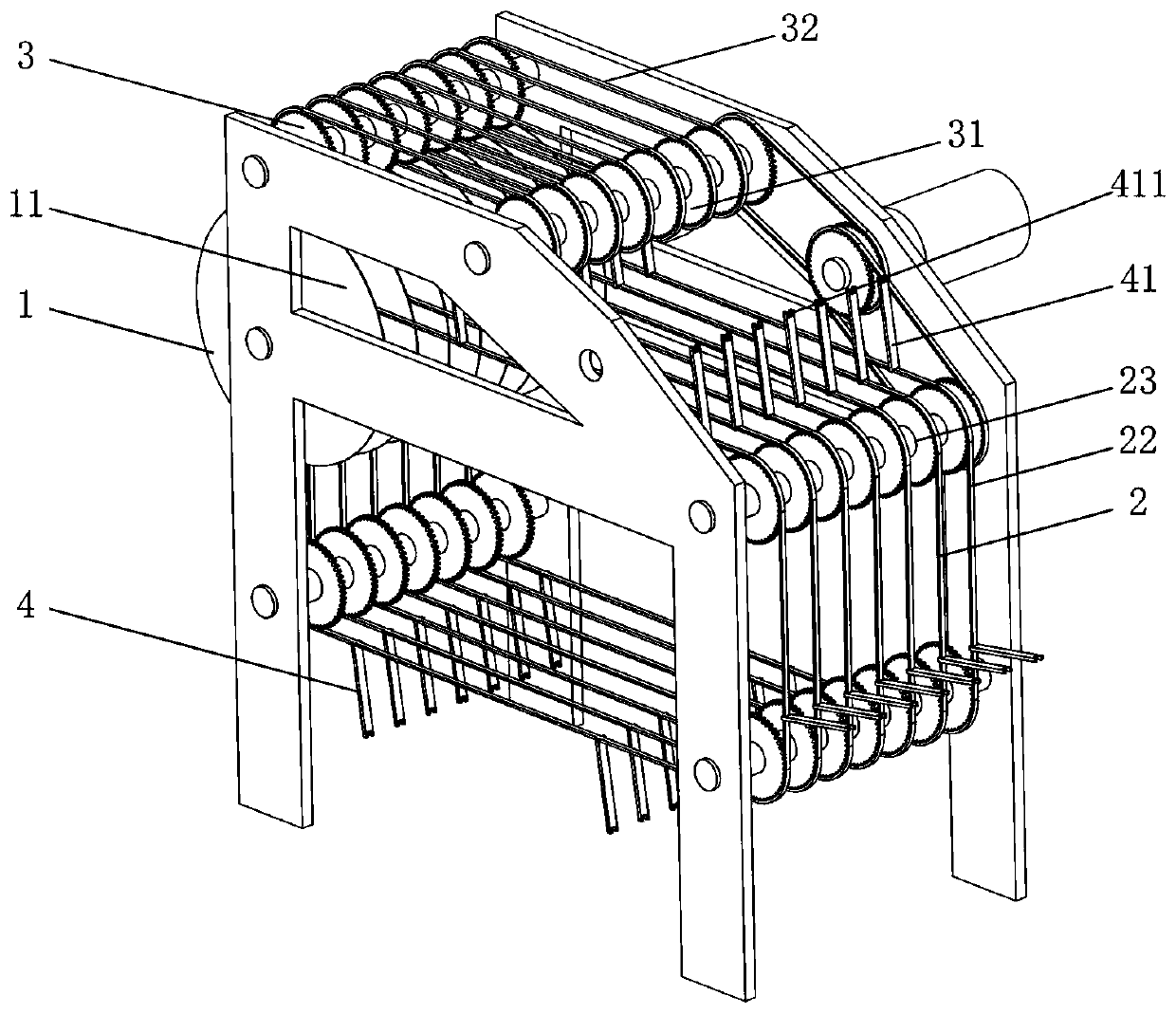

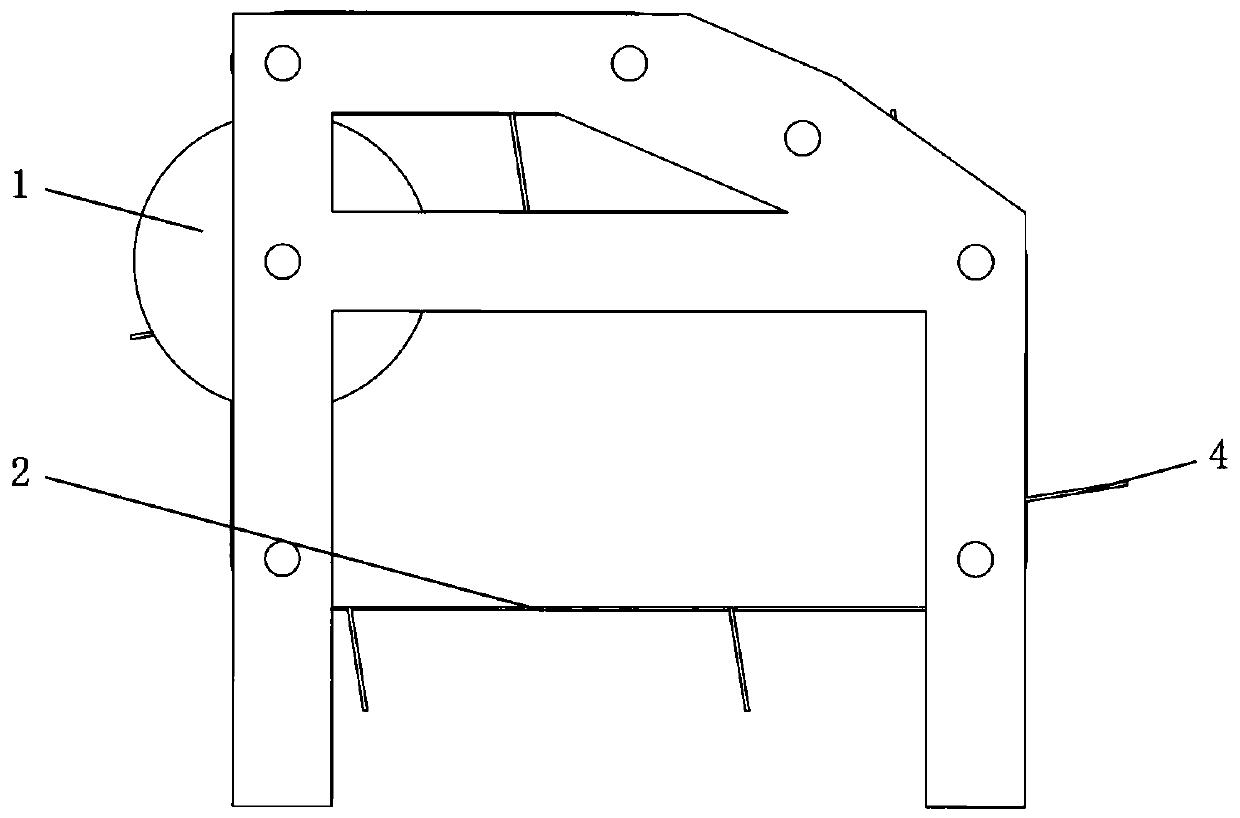

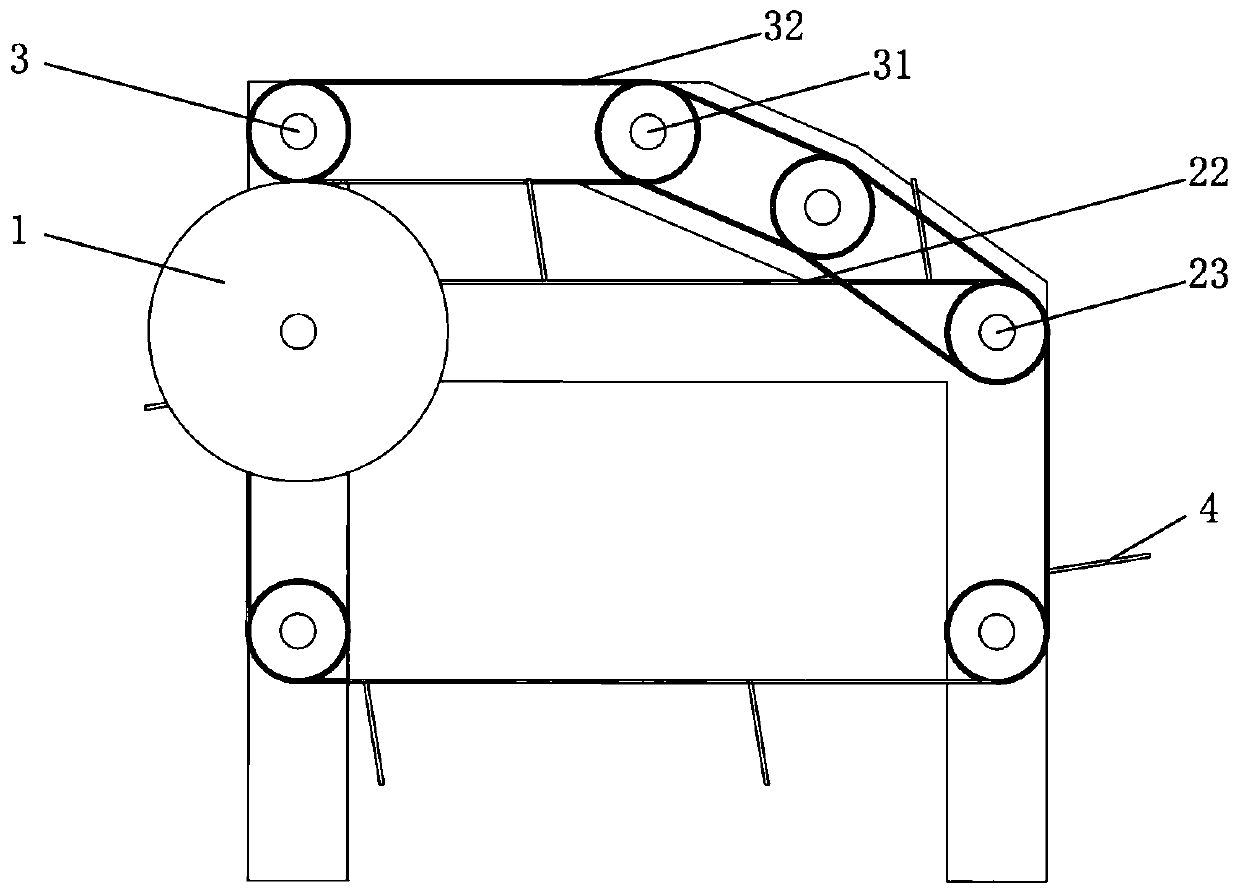

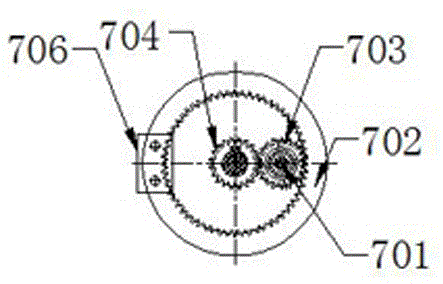

InactiveCN104814070AConsistent output speedTo achieve the purpose of stuffingDough processingSprocketLarge size

The invention relates to an automatic encrusting device, and relates to the field of food processing machines. The automatic encrusting device is characterized by comprising a motor, a support plate, a driving sprocket, a driven sprocket, a supporting seat, an inner gear bearing seat, a material shifting assembly, a hopper assembly, a packing auger assembly and a skin-stuffing assembly, wherein the motor is arranged below one end of the support plate, and the driving sprocket is arranged above one end of the support plate; the supporting seat is arranged below the middle of the support plate, and the inner gear bearing seat is arranged below the other end; the material shifting assembly is arranged above the inner gear bearing seat; the driven sprocket is arranged above the material shifting assembly; the hopper assembly and the packing auger assembly are arranged below the inner gear bearing seat; and the skin-stuffing assembly is arranged below the packing auger assembly. The automatic encrusting device disclosed by the invention can be used for uniformly filling Wu Ren stuffing into a skin material of a moon cake without generating the conditions of blockage and discontinuity of moon cake stuffing and great large size error of the moon cake, thereby uniformly filling the Wu Ren stuffing into the skin material from top to bottom without generating the condition of stuffing turning.

Owner:合肥市开平食品贸易有限责任公司

Automatic stuffing wrapping machine

The invention relates to the field of food processing machinery, in particular to an automatic stuffing wrapping machine. The automatic stuffing wrapping machine is characterized by being composed of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing seat, a stirring component, a hopper component, a winch component and a skin stuffing component, the motor is arranged below one end of the supporting plate, the driving chain wheel is arranged above one end of the supporting plate, the supporting seat is arranged below the middle of the supporting plate, the inner gear bearing seat is arranged below the other end of the supporting plate, the stirring component is arranged above the inner gear bearing seat, the driven chain wheel is arranged above the stirring component, the hopper component and the winch component are arranged below the inner gear bearing seat, and the skin stuffing component is arranged below the winch component. By the automatic stuffing wrapping machine, five-kernel stuffing can be uniformly injected into mooncake skin from top to bottom without causing blockage and discontinuity of mooncake stuffing, great mooncake size error and turning of the stuffing.

Owner:合肥市开平食品贸易有限责任公司

Automatic encrusting device

The invention provides an automatic encrusting device, and relates to the field of food processing machinery. The automatic encrusting device is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing block, a shifting subassembly, a hopper subassembly, an auger subassembly and a wrapper and filling subassembly, wherein the motor is arranged below one end of the supporting plate; the driving chain wheel is arranged above one end of the supporting plate; the supporting seat is arranged below the middle of the supporting plate; the inner gear bearing block is arranged below the other end of the supporting plate; the shifting subassembly is arranged above the inner gear bearing block; the driven chain wheel is arranged above the shifting subassembly; the hopper subassembly and the auger subassembly are arranged below the inner gear bearing block; and the wrapper and filling subassembly is arranged below the auger subassembly. By the automatic encrusting device, fillings with five kernels can be uniformly injected in wrappers of moon cakes, circumstances that fillings of the moon cakes are blocked and intermittent, and difference of sizes of the moon cakes is large are avoided, the fillings with the five kernels can be uniformly injected into the wrappers from top to bottom, and turning of the fillings is avoided.

Owner:合肥市三强调味品厂

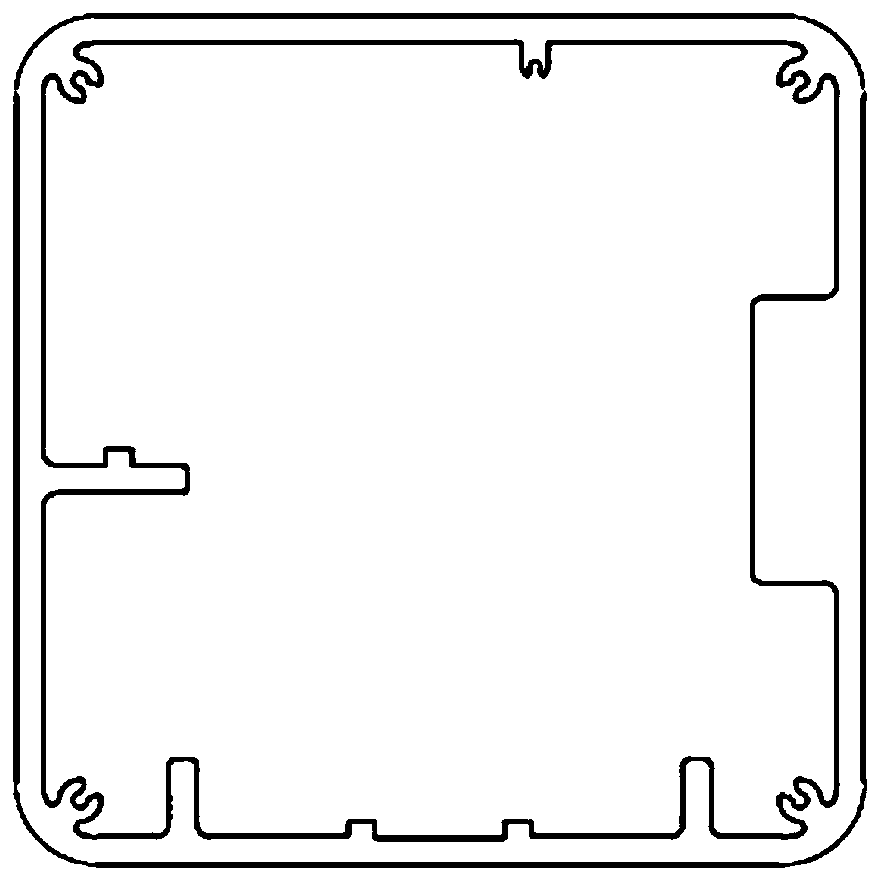

Plastic profile extrusion die head allowing material flow speed at single arm parts to be adjusted

The invention discloses a plastic profile extrusion die head allowing a material flow speed at single arm parts to be adjusted. The plastic profile extrusion die head comprises a neck adapter, a support plate I, a support plate II, a compressing plate, a preforming plate and a forming plate, wherein a gas flow channel distributed in the parison flowing direction is arranged in the position, corresponding to a cavity wall, of each cavity single arm part, of the compressing plate or the preforming plate, and a gas inlet channel and a gas exhaust channel which are communicated with two ends of the gas flow channel are formed in the side wall of the compressing plate or the preforming plate and distributed sequentially in the parison flowing direction; high-temperature and high-pressure gas is guided into the gas flow channel, the cavity single arm parts are locally heated, the flowability can be improved, the temperature or pressure of input gas is adjusted, the temperature of a corresponding area of the preforming plate can be controlled, and speed control of material flow is realized.

Owner:TONGLING GREAT EXTRUSION TECH

Stuffing wrapping machine for moon cakes

The invention discloses a stuffing wrapping machine for moon cakes, and relates to the field of food processing machinery. The stuffing wrapping machine is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing seat, a material poking assembly, a hopper assembly, an auger assembly and a wrapper and stuffing assembly; the motor is arranged below one end of the supporting plate, and the driving chain wheel is arranged above the end of the supporting plate; the supporting seat is arranged below the middle of the supporting plate; the inner gear bearing seat is arranged below the other end of the supporting plate; the material poking assembly is arranged above the inner gear bearing seat; the driven chain wheel is arranged above the material poking assembly; the hopper assembly and the auger assembly are arranged below the inner gear bearing seat; and the wrapper and stuffing assembly is arranged below the auger assembly. According to the stuffing wrapping machine for the moon cakes, a five-kernel stuffing can be uniformly injected into wrappers of the moon cakes, so that conditions that the stuffing of the moon cakes is blocked and intermitted and the size error of the moon cakes is extremely large are not caused; the five-kernel stuffing is uniformly injected into the wrappers from top to bottom, so that the condition that the stuffing is inflected does not exist.

Owner:HEFEI HUAJUN FOOD CO LTD

Automatic encrusting machine

The invention provides an automatic encrusting machine, and relates to the field of food processing machinery. The automatic encrusting machine is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing block, a shifting assembly, a hopper assembly, an auger assembly and a wrapper and stuffing assembly; the motor is arranged below one end of the supporting plate; the driving chain wheel is arranged above one end of the supporting plate; the supporting seat is arranged below the middle of the supporting plate; the inner gear bearing block is arranged below the other end of the supporting plate; the shifting assembly is arranged above the inner gear bearing block; the driven chain wheel is arranged above the shifting assembly; the hopper assembly and the auger assembly are arranged below the inner gear bearing block; the wrapper and stuffing assembly is arranged below the auger assembly. According to the automatic encrusting machine, stuffings with five kernels can be uniformly injected in wrappers of moon cakes, conditions that stuffings of the moon cakes are blocked and intermittent, and difference of sizes of the moon cakes is extremely large are avoided, the stuffings with the five kernels can be uniformly injected into the wrappers from top to bottom, and turning of the stuffings is avoided.

Owner:HEFEI HUAJUN FOOD CO LTD

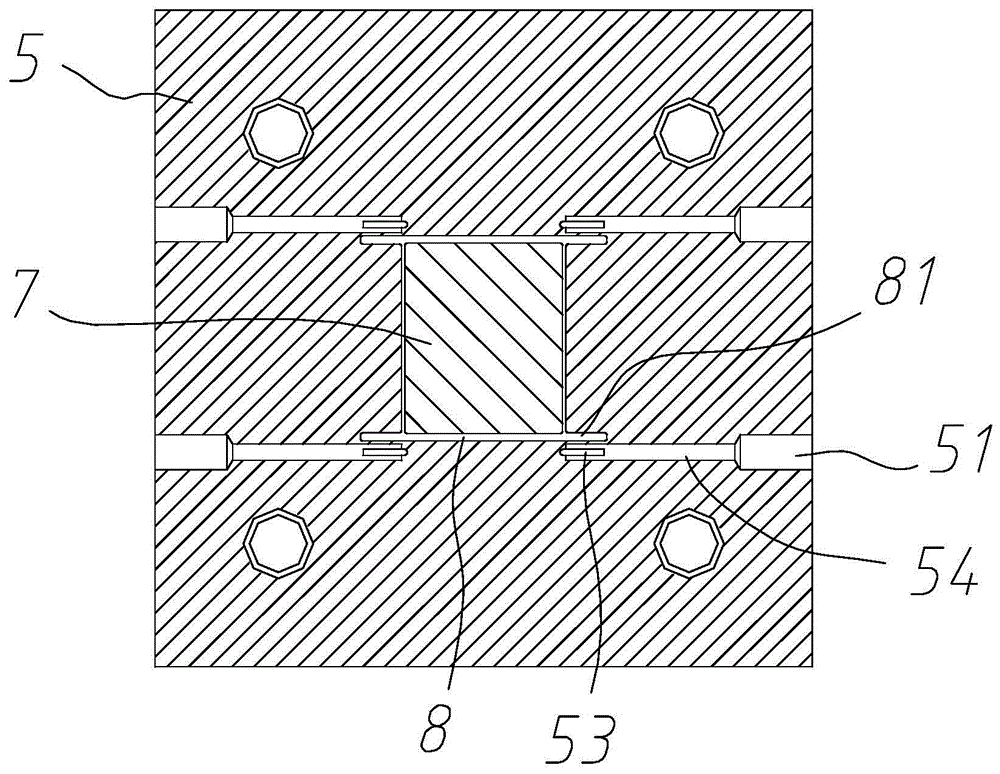

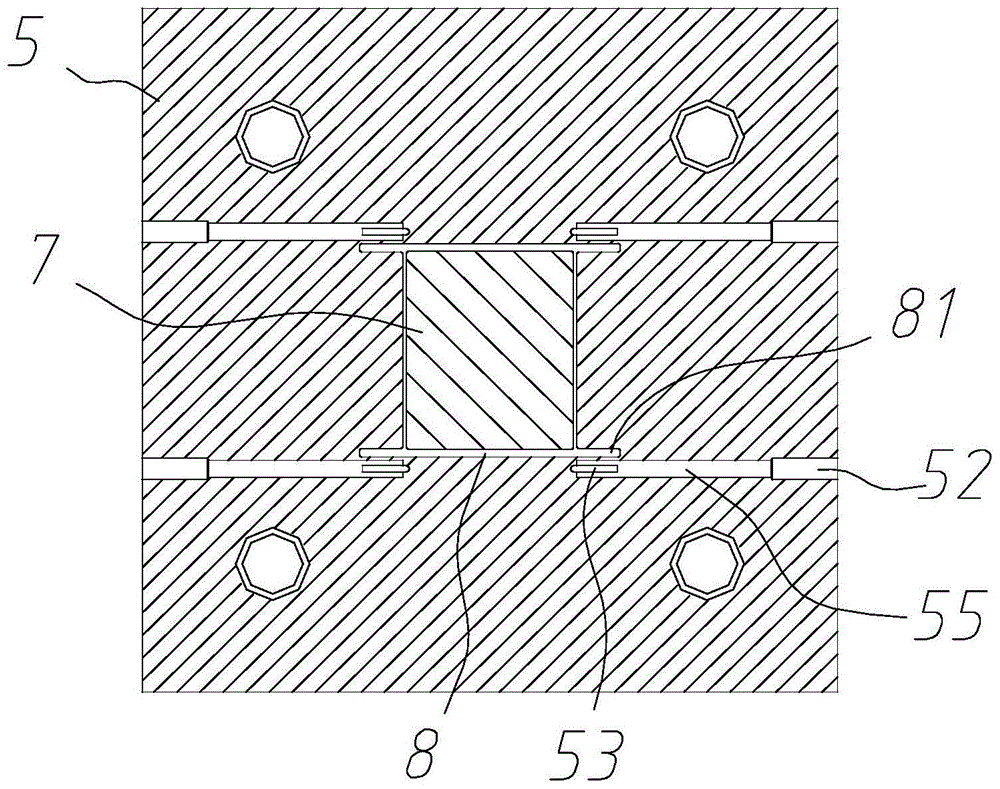

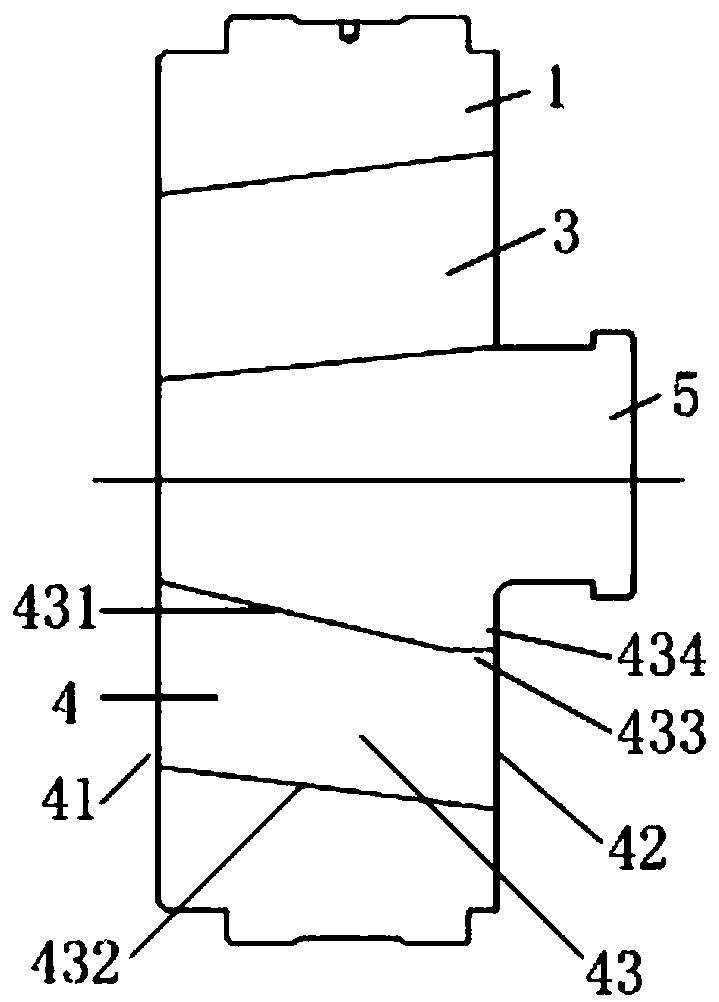

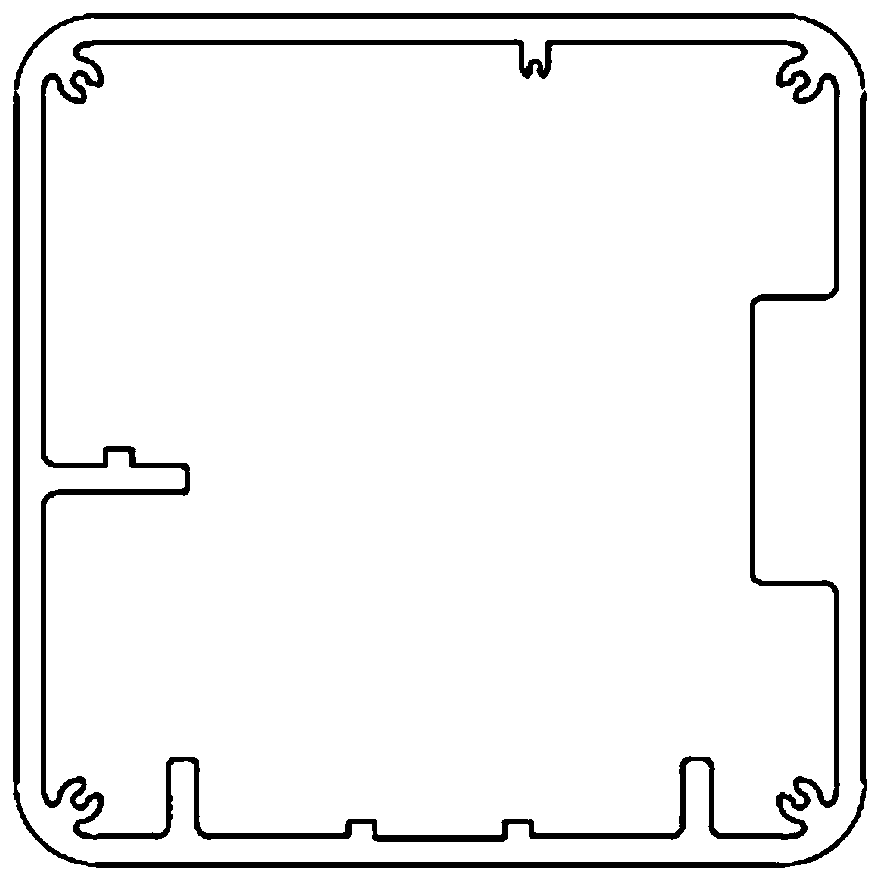

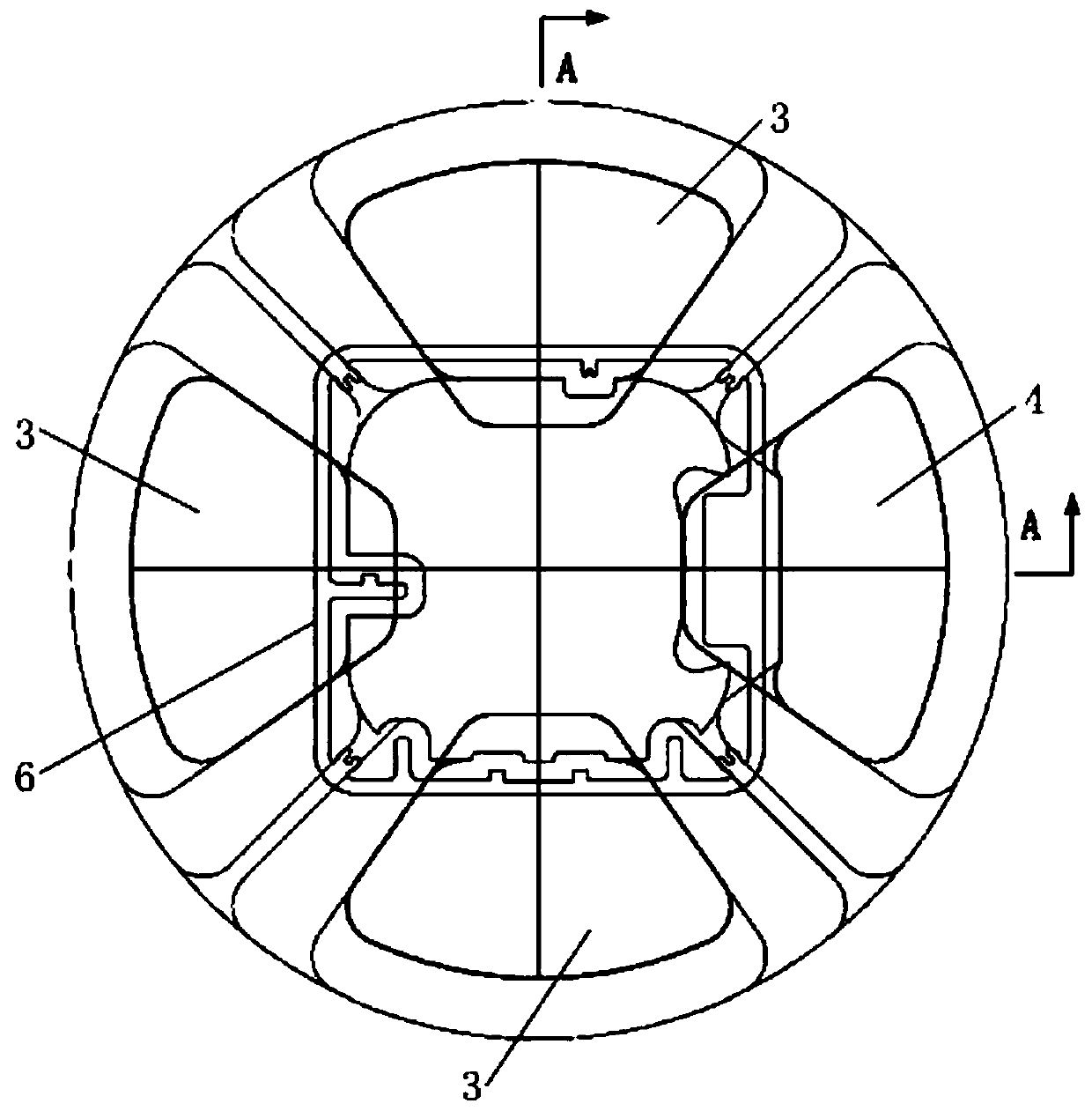

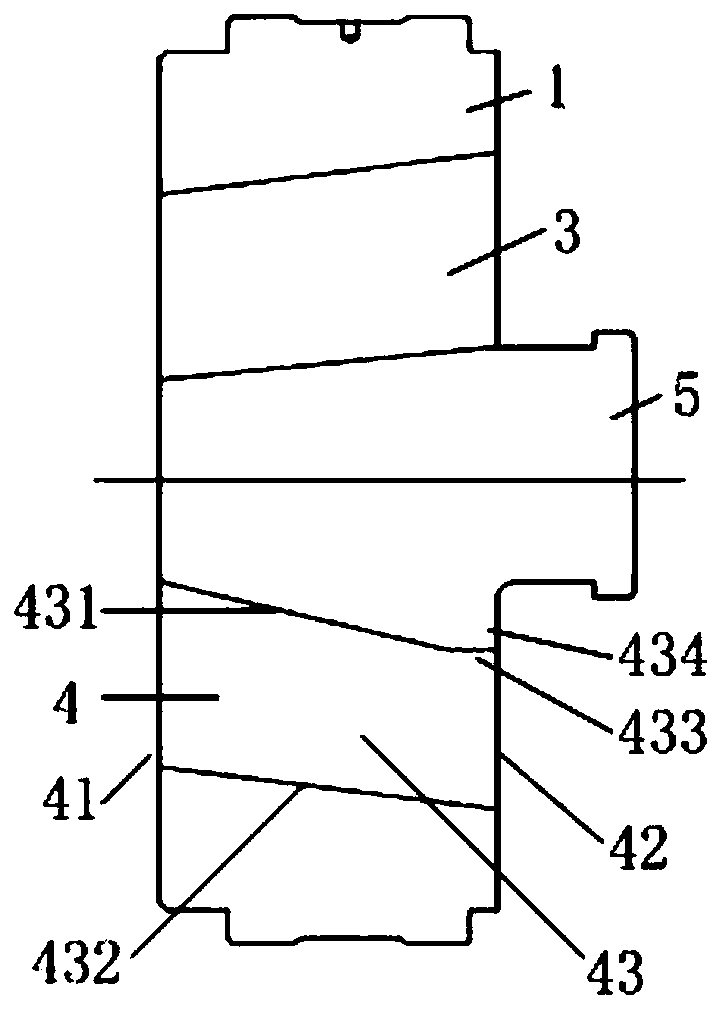

Forming mold for rectangular aluminum alloy provided with convex part

The invention discloses a forming mold for a rectangular aluminum alloy provided with a convex part. The forming mold comprises an upper mold body and a lower mold body. The upper mold body is provided with common distribution holes, a decelerating distribution hole and a mold core. The lower mold body is provided with a mold cavity which is matched with the to-be-formed aluminum alloy provided with the convex part. The mold cavity comprises a rectangular forming part and a convex forming part. The decelerating distribution hole comprises a feeding port located above the convex forming part, adischarging port connected with the convex forming part, and a passage connected with the feeding port and the discharging port, wherein the passage gradually inclines outwards in the radial direction from the feeding port to the discharging port. According to the forming mold for the rectangular aluminum alloy provided with the convex part, the common distribution holes are used for feeding forthe common wall-thickness portions of the rectangular aluminum alloy in the mold cavity, and the decelerating distribution hole is used for feeding for the portion, provided with the convex part, of the rectangular aluminum alloy in the mold cavity so that the flow rate of melt can be controlled under the same extrusion system, it is ensured that the discharging speed of the common wall-thicknessportions and the discharging speed of the portion provided with the convex part are consistent, the internal stress is reduced, and the precision of finished products is improved.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Automatic encrusting device

The invention provides an automatic encrusting device, and relates to the field of food processing machinery. The automatic encrusting device is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing block, a shifting assembly, a hopper assembly, an auger assembly and a wrapper and stuffing assembly; the motor is arranged below one end of the supporting plate; the driving chain wheel is arranged above one end of the supporting plate; the supporting seat is arranged below the middle of the supporting plate; the inner gear bearing block is arranged below the other end of the supporting plate; the shifting assembly is arranged above the inner gear bearing block; the driven chain wheel is arranged above the shifting assembly; the hopper assembly and the auger assembly are arranged below the inner gear bearing block; the wrapper and stuffing assembly is arranged below the auger assembly. According to the automatic encrusting device, stuffings with five kernels can be uniformly injected in wrappers of moon cakes, conditions that stuffings of the moon cakes are blocked and intermittent, and difference of sizes of the moon cakes is extremely large are avoided, the stuffings with the five kernels can be uniformly injected into the wrappers from top to bottom, and turning of the stuffings is avoided.

Owner:HEFEI HUAJUN FOOD CO LTD

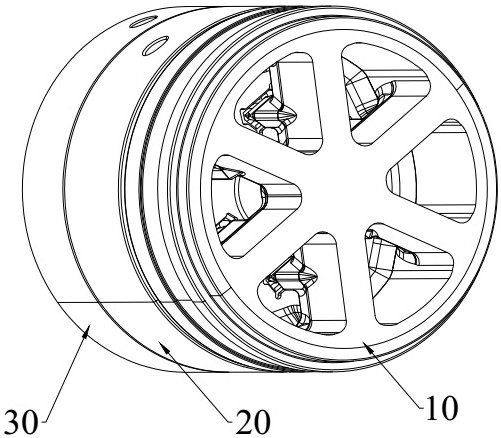

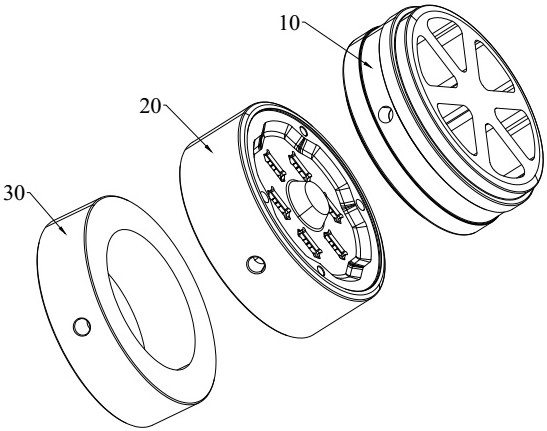

Novel automatic stuffing wrapping machine

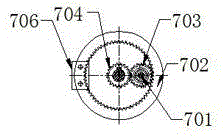

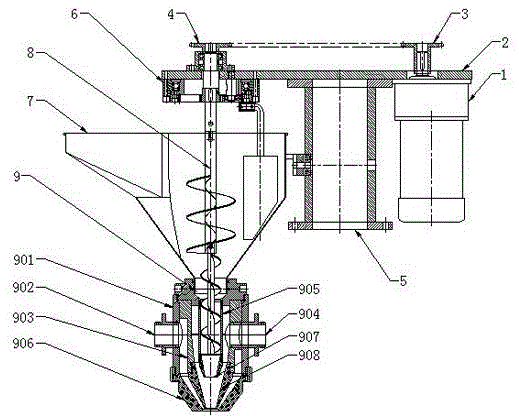

InactiveCN105557822ASmooth dischargeReduce resistanceDough processingEngineeringMechanical engineering

The invention discloses a novel automatic stuffing wrapping machine, and relates to the field of foodstuff processing machinery. The novel automatic stuffing wrapping machine is characterized by comprising a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, a poking assembly, a hopper assembly, an auger assembly and a wrapper and stuffing assembly; the motor is arranged below one end of the supporting plate, and the driving chain wheel is arranged above one end of the supporting plate; the supporting seat is arranged below the middle of the supporting plate; the driven chain wheel is arranged above the other end of the supporting plate, and the poking assembly is arranged below the other end of the supporting plate; the hopper assembly and the auger assembly are arranged below the poking assembly; the wrapper and stuffing assembly is arranged below the auger assembly. The novel automatic stuffing wrapping machine has the advantages that one kind of stuffing can be wrapped by another kind of stuffing without an extra opening, a moon cake wrapper is wrapped with the stuffings finally, and accordingly, time and labor are saved and the efficiency is high.

Owner:HEFEI HUAJUN FOOD CO LTD

Stuffing filling machine for moon cakes

InactiveCN104839266AConsistent output speedTo achieve the purpose of stuffingDough processingGear wheelSprocket

The invention discloses a stuffing filling machine for moon cakes and relates to the field of food processing machinery. The stuffing filling machine is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing seat, a material poking assembly, a hopper assembly, an auger assembly and a peel-stuffing assembly, wherein the motor is arranged below one end of the supporting plate, the driving chain wheel is arranged above the end of the supporting plate, the supporting seat is arranged below the middle of the supporting plate, the inner gear bearing seat is arranged below the other end of the supporting plate, the material poking assembly is arranged above the inner gear bearing seat, the driven chain wheel is arranged above the material poking assembly, the hopper assembly and the auger assembly are arranged below the inner gear bearing seat, and the peel-stuffing assembly is arranged below the auger assembly. According to the stuffing filling machine for moon cakes, five-kernel stuffing can be uniformly injected into the peel of the moon cakes, so that circumstances that the stuffing of the moon cakes is blocked and intermitted and the size error of the moon cakes is large are not caused; the five-kernel stuffing is uniformly injected into the peel from top to bottom, so that the circumstance that the stuffing is inflected does not exist.

Owner:合肥市三强调味品厂

Moon cake encrusting machine

Owner:ANHUI HEFEI WANMEI FOOD TRADING CO LTD

Stuffing filling machine for moon cakes

InactiveCN104839268AConsistent output speedTo achieve the purpose of stuffingBaked article fillingDough processingMechanical engineeringFood processing

The invention discloses a stuffing filling machine for moon cakes and relates to the field of food processing machinery. The stuffing filling machine is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing seat, a material poking assembly, a hopper assembly, an auger assembly and a peel-stuffing assembly, wherein the motor is arranged below one end of the supporting plate, the driving chain wheel is arranged above the end of the supporting plate, the supporting seat is arranged below the middle of the supporting plate, the inner gear bearing seat is arranged below the other end of the supporting plate, the material poking assembly is arranged above the inner gear bearing seat, the driven chain wheel is arranged above the material poking assembly, the hopper assembly and the auger assembly are arranged below the inner gear bearing seat, and the peel-stuffing assembly is arranged below the auger assembly. According to the stuffing filling machine for moon cakes, five-kernel stuffing can be uniformly injected into peel of the moon cakes, so that circumstances that the stuffing of the moon cakes is blocked and intermitted and the size error of the moon cakes is large are not caused; the five-kernel stuffing is uniformly injected into the peel from top to bottom, so that the circumstance that the stuffing is inflected does not exist.

Owner:安徽晟萌粮油食品有限公司

Automatic stuffing wrapping machine

InactiveCN105557817AConsistent output speedTo achieve the purpose of stuffingDough processingSprocketFood processing

The invention provides an automatic stuffing wrapping machine, and relates to the field of food processing machinery. The automatic stuffing wrapping machine is characterized by comprising a motor, a support plate, a drive chain wheel, a driven chain wheel, a support seat, an internal gear bearing pedestal, a material pushing assembly, a material hopper assembly, an auger assembly and a wrapper-stuffing assembly, wherein the motor is arranged below one end of the support plate, the drive chain wheel is arranged above one end of the support plate, the support seat is arranged below the middle of the support plate, the internal gear bearing pedestal is arranged below the other end, the material pushing assembly is arranged above the internal gear bearing pedestal, the driven chain wheel is arranged above the material pushing assembly, the material hopper assembly and the auger assembly are arranged below the internal gear bearing pedestal, and the wrapper-stuffing assembly is arranged below the auger assembly. With the automatic stuffing wrapping machine of the present invention, the five-kernel stuffing can be uniformly injected into the mooncake wrapper material, and the situations such as mooncake stuffing clogging, the discontinuous mooncake stuffing and the extremely high mooncake size error cannot be generated, such that the five-kernel stuffing can be uniformly injected into the mooncake wrapper material, and the stuffing turning situation does not exist.

Owner:HEFEI LAONAINAI FOOD CO LTD

Automatic encrusting device

InactiveCN105557826ASmooth dischargeReduce resistanceDough processingEngineeringMechanical engineering

The invention provides an automatic encrusting device and relates to the field of food processing machines. The automatic encrusting device is characterized by being composed of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting base, an internal gear bearing pedestal, a poking assembly, a hopper assembly, a packing auger assembly and a wrapping stuffing assembly. The motor is arranged below one end of the supporting plate. The driving chain wheel is arranged above one end of the supporting plate. The supporting base is arranged below the middle of the supporting plate. The internal gear bearing pedestal is arranged below the other end of the supporting plate. The poking assembly is arranged above the internal gear bearing pedestal. The driven chain wheel is arranged above the poking assembly. The hopper assembly and the packing auger assembly are arranged below the internal gear bearing pedestal. The wrapping stuffing assembly is arranged below the packing auger assembly. The automatic encrusting device can inject mixed-nut stuffing into mooncake wrapping uniformly, the situations that the mooncake stuffing is blocked or is fed discontinuously, and size errors of mooncakes are extremely large are avoided, the mixed-nut stuffing can be injected into the wrapping uniformly from top to bottom, and stuffing turning is avoided.

Owner:ANHUI HEFEI WANMEI FOOD TRADING CO LTD

Novel automatic filling wrapping machine

The invention discloses a novel automatic filling wrapping machine and relates to the field of food processing machinery. The novel automatic filling wrapping machine is characterized by comprising a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, a poking component, a hopper component, an auger component and a wrapper and filling component, wherein the motor and the driving chain wheel are arranged below and above one end of the supporting plate respectively, the supporting seat is arranged below the middle of the supporting plate, the driven chain wheel and the poking component are arranged above and below the other end of the supporting plate respectively, the hopper component and the auger component are arranged below the poking component, and the wrapper and filling component is arranged below the auger component. The novel automatic filling wrapping machine has the advantages that one kind of filling can be wrapped by another kind of filling without an extra opening, the fillings are wrapped by a mooncake wrapper finally, and accordingly, time saving, labor saving and high efficiency are achieved.

Owner:HEFEI LAONAINAI FOOD CO LTD

Novel automatic filling wrapping machine

InactiveCN104824092AConsistent output speedTo achieve the purpose of stuffingDough processingEngineeringSprocket

The invention discloses a novel automatic filling wrapping machine and relates to the field of foodstuff processing machinery. The novel automatic filling wrapping machine is characterized by comprising a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, a poking component, a hopper component, an auger component and a wrapper and filling component, wherein the motor and the driving chain wheel are arranged below and above one end of the supporting plate respectively, the supporting seat is arranged below the middle of the supporting plate, the driven chain wheel and the poking component are arranged above and below the other end of the supporting plate respectively, the hopper component and the auger component are arranged below the poking component, and the wrapper and filling component is arranged below the auger component. The novel automatic filling wrapping machine has the advantages that one kind of filling can be wrapped by another kind of filling without an extra opening, the fillings are wrapped by a mooncake wrapper finally, and accordingly, time saving, labor saving and high efficiency are achieved.

Owner:合肥市开平食品贸易有限责任公司

Automatic stuffing filling device

The invention discloses an automatic stuffing filling device and relates to the field of food processing machinery. The automatic stuffing filling device is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, an inner gear bearing seat, a material poking assembly, a hopper assembly, an auger assembly and a peel-stuffing assembly, wherein the motor is arranged below one end of the supporting plate, the driving chain wheel is arranged above the end of the supporting plate, the supporting seat is arranged below the middle of the supporting plate, the inner gear bearing seat is arranged below the other end of the supporting plate, the material poking assembly is arranged above the inner gear bearing seat, the driven chain wheel is arranged above the material poking assembly, the hopper assembly and the auger assembly are arranged below the inner gear bearing seat, and the peel-stuffing assembly is arranged below the auger assembly. According to the automatic stuffing filling device, five-kernel stuffing can be uniformly injected into peel of moon cakes, so that circumstances that the stuffing of the moon cakes is blocked and intermitted and the size error of the moon cakes is large are not caused; the five-kernel stuffing is uniformly injected into the peel from top to bottom, so that the circumstance that the stuffing is inflected does not exist.

Owner:安徽晟萌粮油食品有限公司

Automatic stuffing wrapping apparatus

InactiveCN105557816ASmooth dischargeReduce resistanceDough processingEngineeringMechanical engineering

The invention provides an automatic stuffing wrapping apparatus, and relates to the field of food processing machinery. The automatic stuffing wrapping apparatus is characterized by comprising a motor, a support plate, a drive chain wheel, a driven chain wheel, a support seat, an internal gear bearing pedestal, a material pushing assembly, a material hopper assembly, an auger assembly and a wrapper-stuffing assembly, wherein the motor is arranged below one end of the support plate, the drive chain wheel is arranged above one end of the support plate, the support seat is arranged below the middle of the support plate, the internal gear bearing pedestal is arranged below the other end, the material pushing assembly is arranged above the internal gear bearing pedestal, the driven chain wheel is arranged above the material pushing assembly, the material hopper assembly and the auger assembly are arranged below the internal gear bearing pedestal, and the wrapper-stuffing assembly is arranged below the auger assembly. With the automatic stuffing wrapping apparatus of the present invention, the five-kernel stuffing can be uniformly injected into the mooncake wrapper material, and the situations such as mooncake stuffing clogging, the discontinuous mooncake stuffing and the extremely high mooncake size error cannot be generated, such that the five-kernel stuffing can be uniformly injected into the mooncake wrapper material, and the stuffing turning situation does not exist.

Owner:HEFEI LAONAINAI FOOD CO LTD

Novel automatic encrusting machine

InactiveCN105961474AConsistent output speedTo achieve the purpose of stuffingDough processingBiochemical engineeringElectric machinery

The invention discloses a novel automatic encrusting machine, and relates to the field of food processing machinery. The novel automatic encrusting machine is characterized by consisting of a motor, a support plate, a driving chain wheel, a driven chain wheel, a support seat, a stirring component, a hopper component, an auger component and a crust and stuffing component, wherein the motor is arranged below one end I of the support plate, and the driving chain wheel is arranged above the end I of the support plate; the support seat is arranged below the middle of the support plate; the driven chain wheel is arranged above the other end II of the support plate, and the stirring component is arranged below the end II of the support plate; the hopper component and the auger component are arranged below the stirring component; the crust and stuffing component is arranged below the auger component. According to the novel automatic encrusting machine, a stuffing can be encrusted with another stuffing and finally encrusted with a moon cake crust without forming of an additional opening, so that the novel automatic encrusting machine is time-saving, labor-saving and high in efficiency.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Automatic encrusting machine

The invention provides an automatic encrusting machine and relates to the field of food processing machines. The automatic encrusting machine is characterized by being composed of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting base, an internal gear bearing pedestal, a poking assembly, a hopper assembly, a packing auger assembly and a wrapping stuffing assembly. The motor is arranged below one end of the supporting plate. The driving chain wheel is arranged above one end of the supporting plate. The supporting base is arranged below the middle of the supporting plate. The internal gear bearing pedestal is arranged below the other end of the supporting plate. The poking assembly is arranged above the internal gear bearing pedestal. The driven chain wheel is arranged above the poking assembly. The hopper assembly and the packing auger assembly are arranged below the internal gear bearing pedestal. The wrapping stuffing assembly is arranged below the packing auger assembly. The automatic encrusting machine can inject five kernel stuffing into mooncake wrapping uniformly, the situations that the mooncake stuffing is blocked or is fed discontinuously, and size errors of mooncakes are extremely large are avoided, the mixed-nut stuffing can be injected into the wrapping uniformly from top to bottom, and stuffing turning is avoided.

Owner:ANHUI HEFEI WANMEI FOOD TRADING CO LTD

Automatic encrusting machine

InactiveCN105935067ASmooth dischargeReduce resistanceDough processingEngineeringMechanical engineering

The invention discloses an automatic encrusting machine, and relates to the field of food processing machinery. The automatic encrusting machine is characterized by being composed of a motor, a support plate, a driving chain wheel, a driven chain wheel, a support seat, an internal gear bearing seat, a material pulling assembly, a hopper assembly, an auger assembly, and a coating and stuffing assembly. The motor is arranged under one end of the support plate. The driving chain wheel is arranged above the support plate. The support seat is arranged under the center of the support plate. The internal gear bearing seat is arranged under the other end of the support plate. The material pulling assembly is arranged above the internal gear bearing seat. The driven gear is arranged above the material pulling assembly. The hopper assembly and the auger assembly are arranged under the internal gear bearing seat. The coating and stuffing assembly is arranged under the auger assembly. The provided automatic encrusting machine can uniformly inject nut stuffing into coating of moon cake, the moon cake stuffing will not be obstructed or broken, the size of moon cake is uniform, the nut stuffing is uniformly injected into the coating from up to bottom, and the stuffing is not bent during the process.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Stuffing machine of moon cakes

The present invention discloses a stuffing machine of moon cakes and relates to the machinery field of food processing. The stuffing machine is characterized by consisting of an electric motor, a support plate, a driving chain wheel, a driven chain wheel, a support seat, an internal gear bearing seat, a material stirring assembly, a material hopper assembly, a packing auger assembly and a skin filling material assembly. The electric motor is arranged at the lower part of one end of the support plate, the driving chain wheel is arranged at the upper part, the support seat is arranged at the lower part of the middle of the support plate, the internal gear bearing seat is arranged at the lower part of the other end, the material stirring assembly is arranged at the upper part of the internal gear bearing seat, the driven chain wheel is arranged at the upper part of the material stirring assembly, the material hopper assembly and packing auger assembly are arranged at the lower part of the internal gear bearing seat, and the skin filling material assembly is arranged at the lower part of the packing auger assembly. The stuffing machine can evenly inject five kernel filling materials into the skin materials of the moon cakes, the situations that the filling materials of the moon cakes are clogged and intermittent, and the errors of moon cake sizes are extremely great do not happen, the filling materials of the five kernels are evenly injected into the skin materials from top to bottom, and no situation of filling material turning around exists.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Chipping machine for producing oriented strand boards on basis of plant stems

The invention provides a chipping machine for producing oriented strand boards on the basis of plant stems. The chipping machine comprises a chipping knife set, a feeding device and a martial blockingdevice. A material push plate set is fixed to the feeding device. The end portions of all material push plates in the material push plate set are connected with the material blocking device in a clamping manner when moving to the portion below the material blocking device along with the feeding device. When materials move to the chipping knife set, a closed area is formed on the periphery of thematerials through the material push plates and the material blocking device, and therefore the materials are limited both in the vertical direction and the feeding direction and cannot move or fall, and it is ensured that the materials can make contact with the chipping knife set. The chipping machine for producing the oriented strand boards on the basis of the plant stems has the beneficial effects of being uniform in produced segment length, high in discharging speed and high in production efficiency.

Owner:安乡汉创新材料科技有限公司

A rectangular aluminum alloy forming die with a protruding part

ActiveCN108787776BHigh precisionConsistent output speedExtrusion diesInternal stressMaterials science

The invention discloses a forming mold for a rectangular aluminum alloy provided with a convex part. The forming mold comprises an upper mold body and a lower mold body. The upper mold body is provided with common distribution holes, a decelerating distribution hole and a mold core. The lower mold body is provided with a mold cavity which is matched with the to-be-formed aluminum alloy provided with the convex part. The mold cavity comprises a rectangular forming part and a convex forming part. The decelerating distribution hole comprises a feeding port located above the convex forming part, adischarging port connected with the convex forming part, and a passage connected with the feeding port and the discharging port, wherein the passage gradually inclines outwards in the radial direction from the feeding port to the discharging port. According to the forming mold for the rectangular aluminum alloy provided with the convex part, the common distribution holes are used for feeding forthe common wall-thickness portions of the rectangular aluminum alloy in the mold cavity, and the decelerating distribution hole is used for feeding for the portion, provided with the convex part, of the rectangular aluminum alloy in the mold cavity so that the flow rate of melt can be controlled under the same extrusion system, it is ensured that the discharging speed of the common wall-thicknessportions and the discharging speed of the portion provided with the convex part are consistent, the internal stress is reduced, and the precision of finished products is improved.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Moon cake filling wrapping machine

A mooncake stuffing machine relates to the field of food processing machinery. It is characterized in that it is composed of a motor, a support plate, a driving sprocket, a driven sprocket, a support seat, an internal gear bearing seat, a material shifting assembly, a hopper assembly, an auger assembly, and a leather stuffing assembly. One end of the support plate A motor is arranged below, a driving sprocket is arranged above, a support seat is arranged under the middle of the support plate, an internal gear bearing seat is arranged under the other end, a dial assembly is arranged above the inner gear bearing seat, and a driven assembly is arranged above the dial assembly. For the sprocket, a hopper assembly and an auger assembly are arranged under the bearing seat of the internal gear, and a leather stuffing assembly is arranged under the auger assembly. The invention can evenly inject the Wuren filling into the skin of the moon cake without clogging, discontinuity and great error of the size of the moon cake, and inject the Wuren filling into the skin evenly from top to bottom , there is no turning of the stuffing.

Owner:方德森

Automatic stuffing device

The present invention discloses an automatic stuffing device and relates to the machinery field of food processing. The stuffing device is characterized by consisting of an electric motor, a support plate, a driving chain wheel, a driven chain wheel, a support seat, an internal gear bearing seat, a material stirring assembly, a material hopper assembly, a packing auger assembly and a skin filling material assembly. The electric motor is arranged at the lower part of one end of the support plate, the driving chain wheel is arranged at the upper part, the support seat is arranged at the lower part of the middle of the support plate, the internal gear bearing seat is arranged at the lower part of the other end, the material stirring assembly is arranged at the upper part of the internal gear bearing seat, the driven chain wheel is arranged at the upper part of the material stirring assembly, the material hopper assembly and packing auger assembly are arranged at the lower part of the internal gear bearing seat, and the skin filling material assembly is arranged at the lower part of the packing auger assembly. The stuffing device can evenly inject five kernel filling materials into the skin materials of the moon cakes, the situations that the filling materials of the moon cakes are clogged and intermittent, and the errors of moon cake sizes are extremely great do not happen, the filling materials of the five kernels are evenly injected into the skin materials from top to bottom, and no situation of filling material turning around exists.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

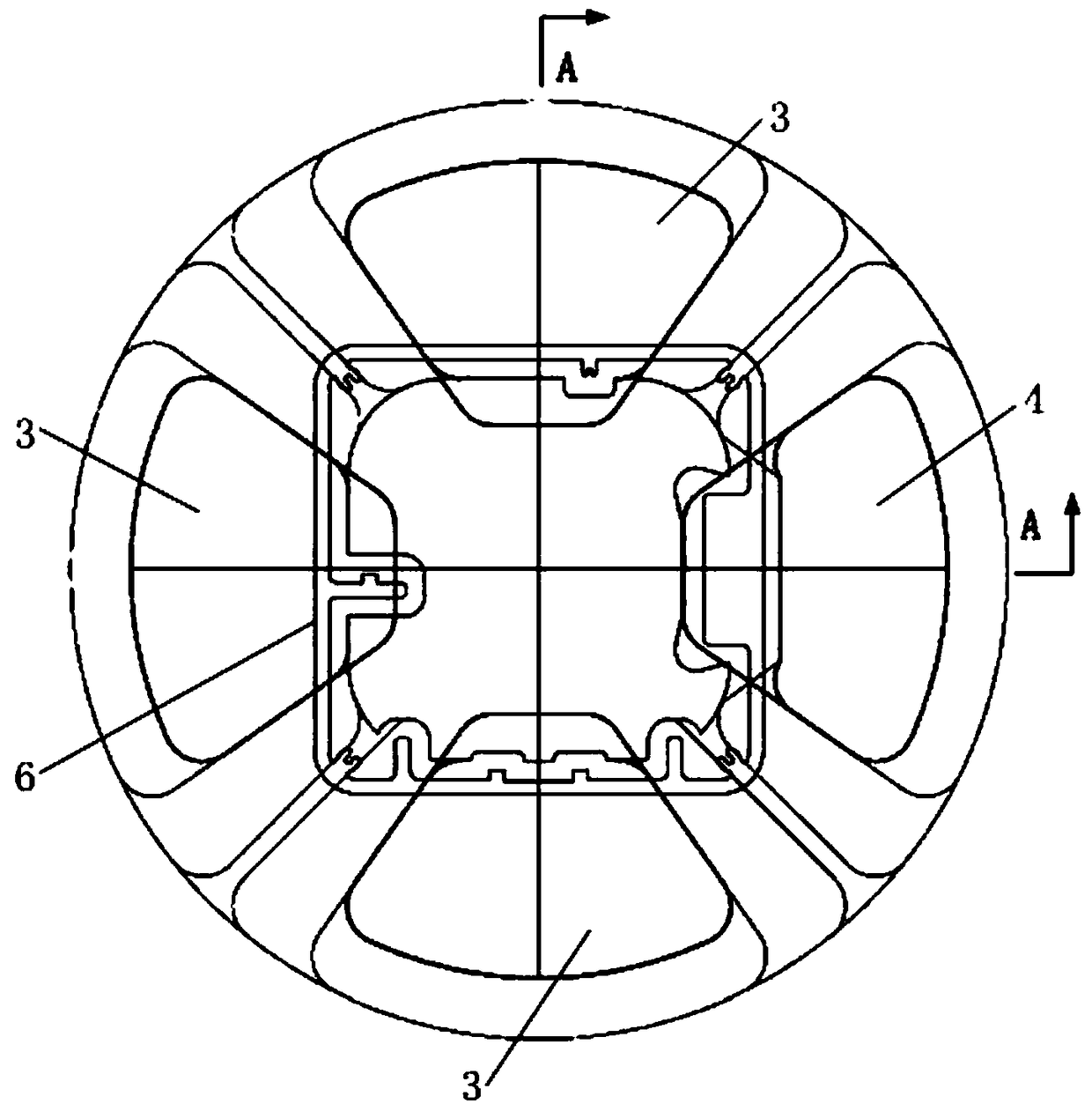

Multi-hole flow dividing mold

The invention discloses a multi-hole flow dividing mold. The multi-hole flow dividing mold comprises an upper mold body and a lower mold body which are coaxially arranged, wherein the upper mold body comprises a core head located in the center and a plurality of flow dividing holes evenly distributed around the core head by a circle, and every two adjacent flow dividing holes are separated by a flow dividing bridge; a groove is formed in one side, close to the upper mold body, of the lower mold body; an integrated welding chamber is formed between the groove and each flow dividing bridge, and each welding chamber communicates with one flow dividing hole; and a boss coaxial with the lower mold body is arranged in the center of the groove and abuts against the core head. Through the unique design of the flow dividing holes and the welding chambers, the integrated multi-hole flow dividing mold is formed, so that the problems of the uniformity of aluminum flow and the size effect of a large extrusion mold are solved through the integrated welding chambers and the evenly and circumferentially arranged flow dividing holes, and the design of optimizing the flow dividing holes and the flow dividing bridges, the strength of the flow dividing bridges and the strength of the mold can be effectively improved, the uniformity of the aluminum flow is effectively improved, dead zone metal staying in the mold is reduced, the tail shrinkage lengths of profiles are reduced, and the yield is increased.

Owner:广西南南铝加工有限公司

Novel automatic stuffing wrapping machine

InactiveCN107041396ASmooth dischargeReduce resistanceDough processingEngineeringMechanical engineering

The invention provides a novel automatic stuffing wrapping machine, and relates to the field of food processing machinery. The novel automatic stuffing wrapping machine is characterized by consisting of a motor, a support plate, a driving chain wheel, a driven chain wheel, a support seat, a material moving assembly, a hopper assembly, a packing auger assembly and a wrapper and stuffing assembly, wherein the motor is arranged at the lower part of one end of the support plate; the driving chain wheel is arranged at the upper side of the one end of the support plate; the support seat is arranged at the lower side of the middle of the support plate; the driven chain wheel is arranged at the upper side of the other end of the support plate; the material moving assembly is arranged at the lower side of the other end of the support plate; the hopper assembly and the packing auger assembly are arranged at the lower side of the material moving assembly; the wrapper and stuffing assembly is arranged at the lower side of the packing auger assembly. The novel automatic stuffing wrapping machine has the advantages that one kind of stuffing can be wrapped into another kind of stuffing without additionally opening; the two kinds of stuffing are finally wrapped into a mooncake wrapper material; the time and the labor are saved; the efficiency is high.

Owner:安徽新桥都市农业开发有限责任公司

Novel automatic encrusting machine

InactiveCN105557830AConsistent output speedTo achieve the purpose of stuffingDough processingMechanical engineeringEngineering

The invention provides a novel automatic encrusting machine and relates to the field of foodstuff processing machinery. The novel automatic encrusting machine is characterized by consisting of a motor, a supporting plate, a driving chain wheel, a driven chain wheel, a supporting seat, a material poking assembly, a hopper assembly, an auger assembly and a wrapper and stuffing assembly, wherein the motor is arranged under the supporting plate, the driving chain wheel is arranged above the supporting plate, the supporting seat is arranged under the middle of the supporting plate, the driven chain wheel is arranged above the other end of the supporting plate, the material poking assembly is arranged under the supporting plate, the hopper assembly and the auger assembly are arranged under the material poking assembly, and the wrapper and stuffing assembly is arranged under the auger assembly. The novel automatic encrusting machine can wrap a stuffing with another stuffing without additional opening and finally wrap the stuffing into wrappers, saves labors and time and is high in efficiency.

Owner:ANHUI HEFEI WANMEI FOOD TRADING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com