Chipping machine for producing oriented strand boards on basis of plant stems

An oriented strand board and plant stem technology, which is applied in the manufacture of thin wood chips, wood processing appliances, manufacturing tools, etc., can solve the problems of slow discharge speed, poor chipping effect, matching feeding speed, etc., to improve uniformity. , Improve production efficiency and avoid the effect of stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

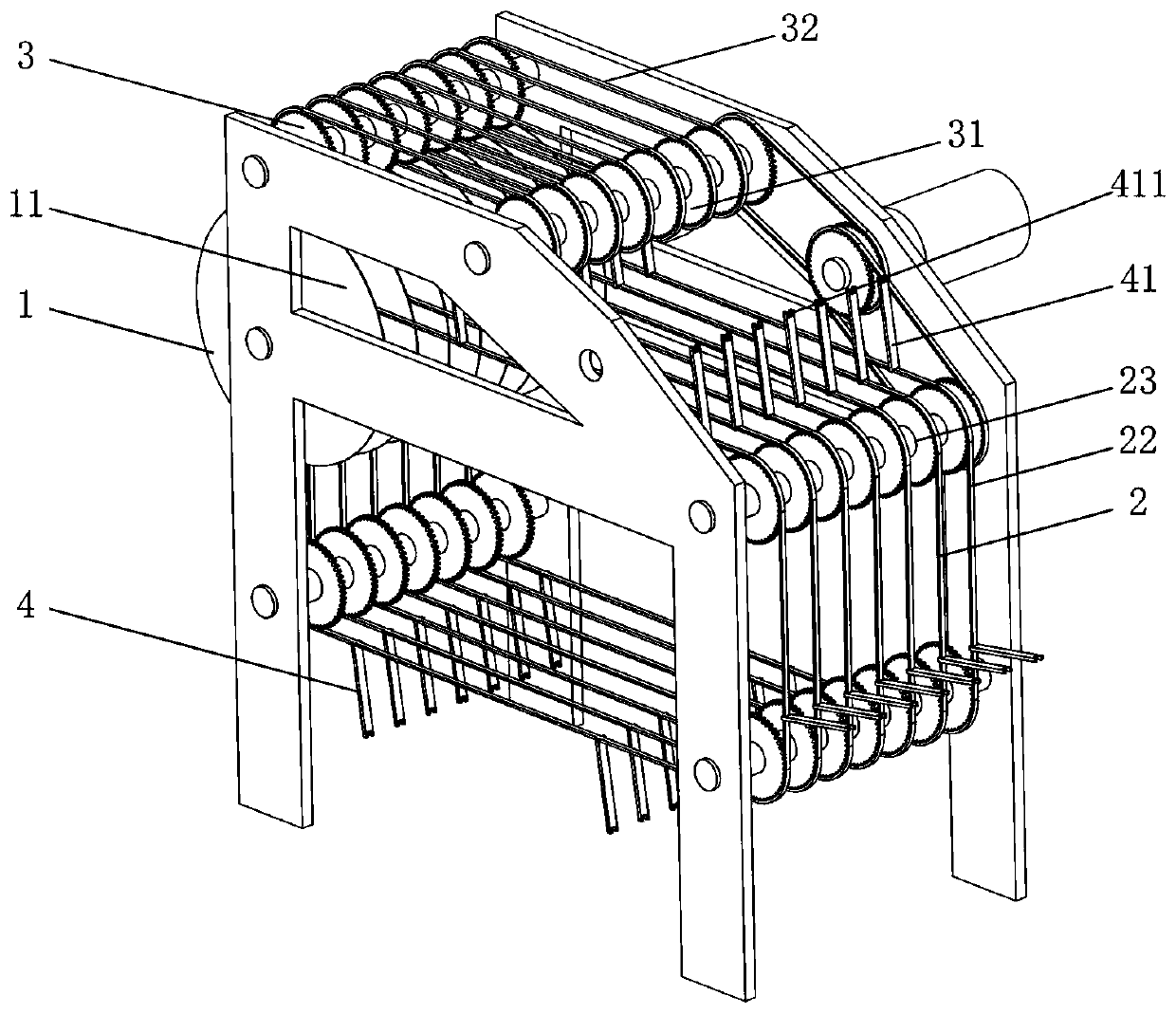

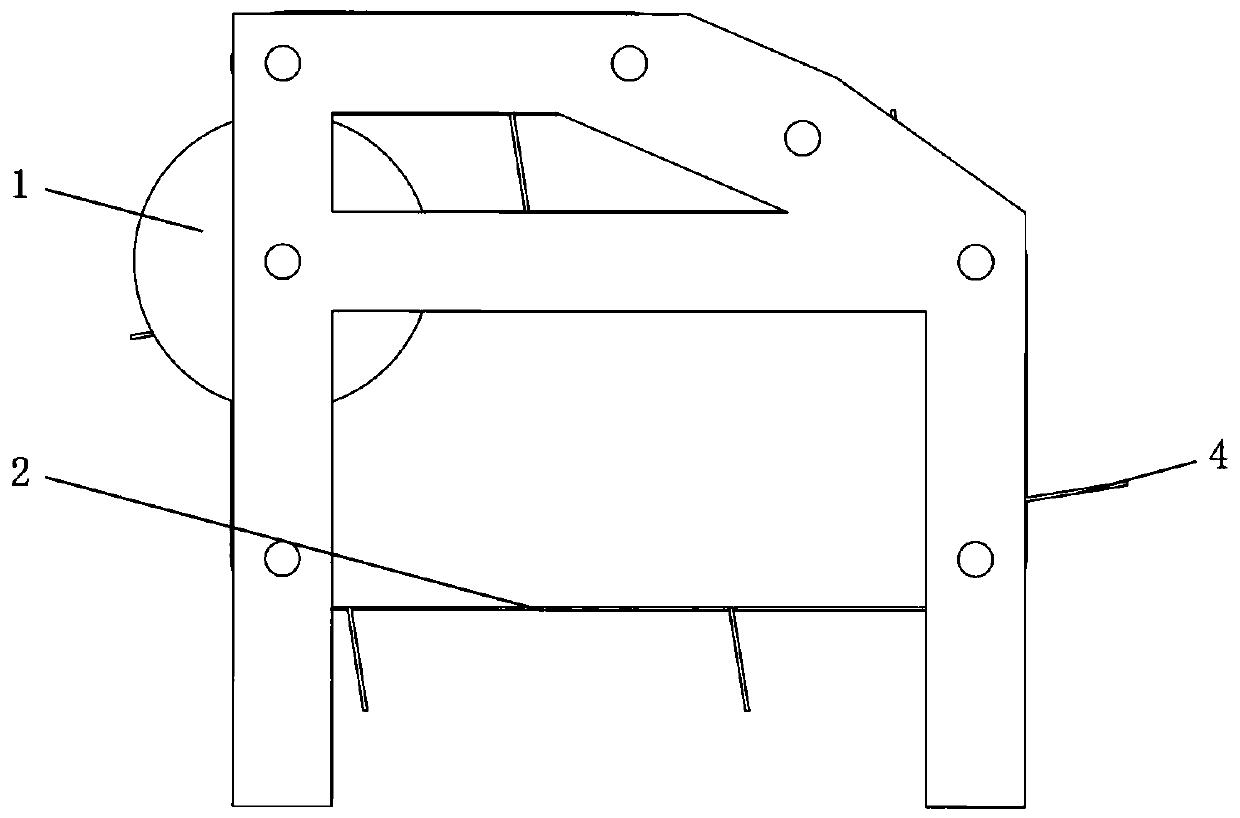

[0044] like Figure 1 to Figure 3 Shown, the chipper that produces oriented strand board based on plant stem bar of the present embodiment comprises:

[0045] The chipping knife set 1 is composed of a plurality of rotating blades 11 distributed axially at intervals along the rotating shaft;

[0046] The feeding device 2 is used to drive the material to be cut to move toward the chipping knife set 1;

[0047] The blocking device 3 is arranged above the feeding device 2, and is used to compress the material when cutting the material;

[0048] And a plurality of pusher plate groups 4 that are distributed in a comb-like shape and can pass between the rotating blades 11;

[0049] One end of each pusher plate 41 in the pusher plate group 4 is fixed on the feeder 2, and the other end moves to the bottom of the stopper 3 with the feeder 2 to form a clamping connection with the stopper 3. During the movement of the knife group 1, the pusher plate 41 and the stopper device 3 always m...

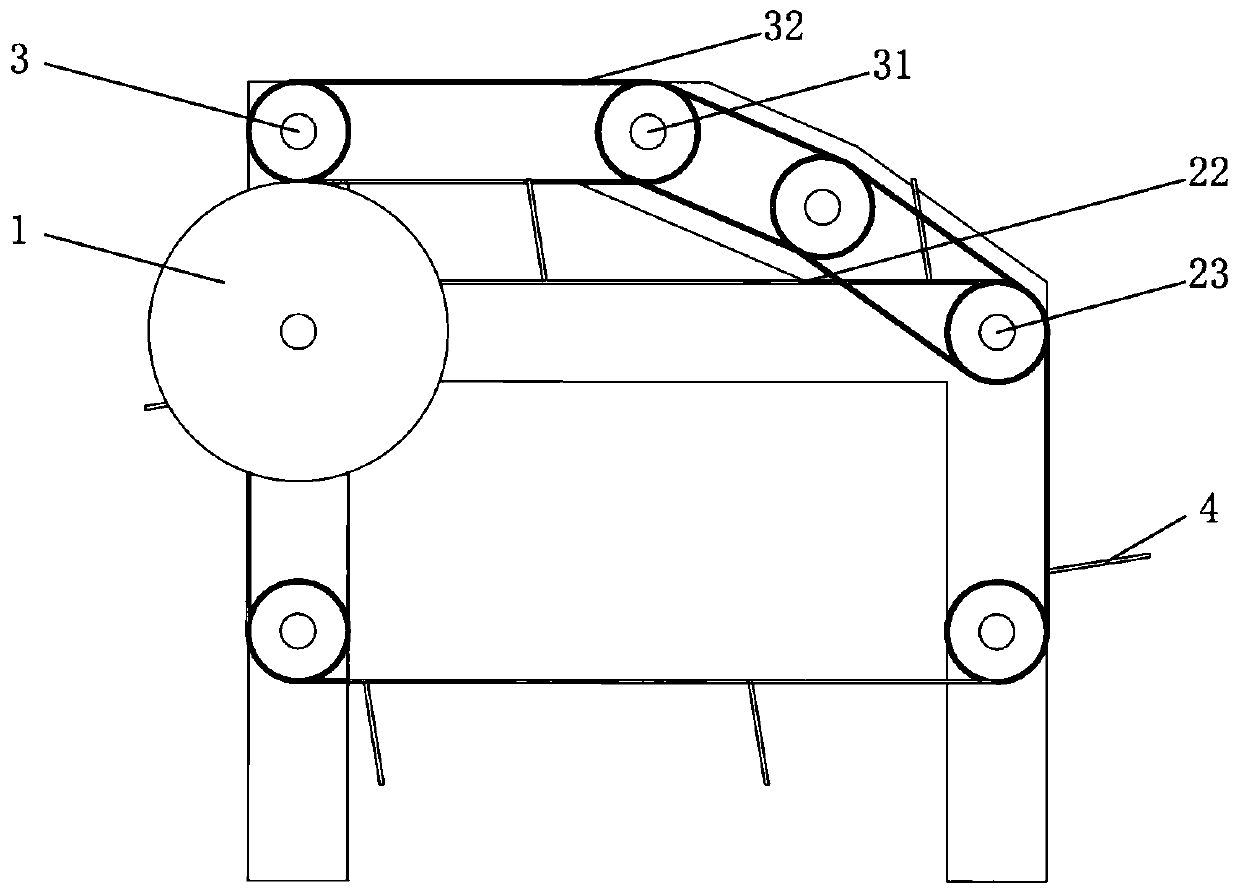

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, the only difference is that this embodiment is such as Figure 5 As shown, the clamping groove 411 is a through groove with an opening facing the material retaining chain 32 arranged along the laying direction of the retaining chain 32, and the width of the retaining groove 411 is greater than the width of the chain plate of the retaining chain 32 and less than the pin length of the retaining chain 32 . When the pushing plate 41 moves to the bottom of the material blocking device 3, the opening of the slot 411 is automatically locked into the chain plate of the material blocking chain 32, and the material will apply a thrust force to the pushing plate 41 in a direction opposite to the feeding direction. , and because the width of the slot 411 is smaller than the length of the pin shaft of the retaining chain 32, it will not be turned outward by the thrust, but will always remain in the clamping state until the feedi...

Embodiment 3

[0058] This embodiment is basically the same as Embodiment 1 and Embodiment 2, the difference is: the feeding device 2 of this embodiment is as Image 6 As shown, it includes a plurality of feed holding bars 21 that are horizontal and distributed in a comb-like shape and can pass between the rotating blades 11, and each feed holding bar 21 is provided with a pushing plate 41; The material holder bar 21 reciprocates along the direction perpendicular to the axial direction of the chipping knife set 1 , and can feed material without interfering with the rotating blade 11 . The feeding support bars 21 in this embodiment are fixedly connected at the ends and driven synchronously by a single driving member, which is beneficial to the synchronization of feeding and can also save driving energy. In other implementation manners, it is also possible to adopt a manner in which each feeding support bar 21 is individually driven, and details are not described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com