Automatic encrusting device

A filling and automatic technology, applied in baking, dough processing, food science, etc., can solve the problems of increasing the resistance of filling, difficulty in filling, and clogging of fillings, and achieve the effect of reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

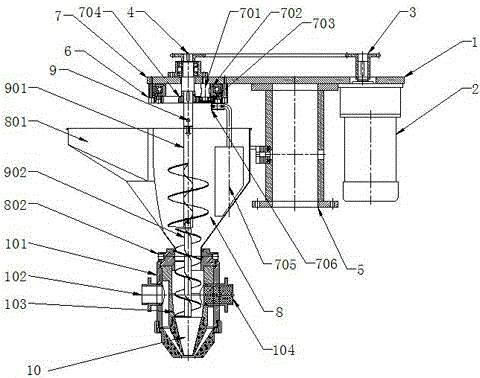

[0013] refer to Figure 1-2 , this specific embodiment adopts the following technical solutions: it consists of a support plate 1, a motor 2, a driving sprocket 3, a driven sprocket 4, a support seat 5, an internal gear bearing seat 6, a material shifting assembly 7, a hopper assembly 8, a twisting Dragon component 9 and leather stuffing component 10, motor 2 is set under one end of the support plate 1, driving sprocket 3 is set above, support seat 5 is set under the middle of support plate 1, and an internal gear is set under the other end The bearing seat 6 is provided with a material shifting assembly 7 above the inner gear bearing seat 6, the driven sprocket 4 is arranged above the material dialing assembly 7, the hopper assembly 8 and the auger assembly 9 are arranged below the internal gear bearing seat 6, and the auger assembly 9 below is provided with skin stuffing assembly 10.

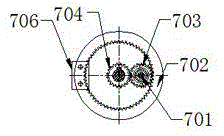

[0014] The shifting assembly 7 includes a transition gear shaft 701, a driven internal ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com