Hydraulic Control System of Pipe Feeder of Mixed Explosives Vehicle

A technology of a hydraulic control system and an explosive vehicle, applied in the field of hydraulic control systems, can solve the problems of destroying the fluid structure, increasing the deformation of the drug delivery tube 34, and failing to achieve pressure compensation, so as to ensure personal safety, high efficiency, and improve operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout.

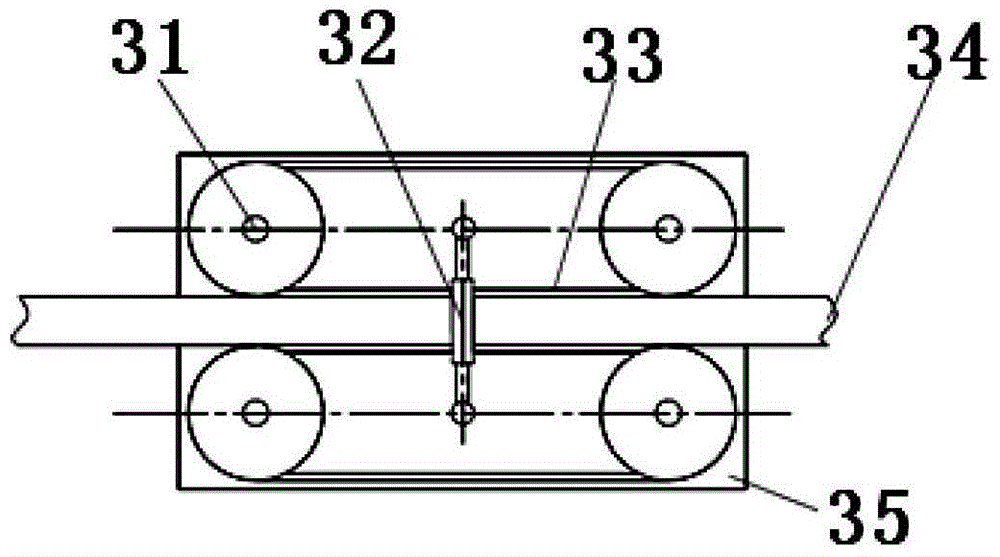

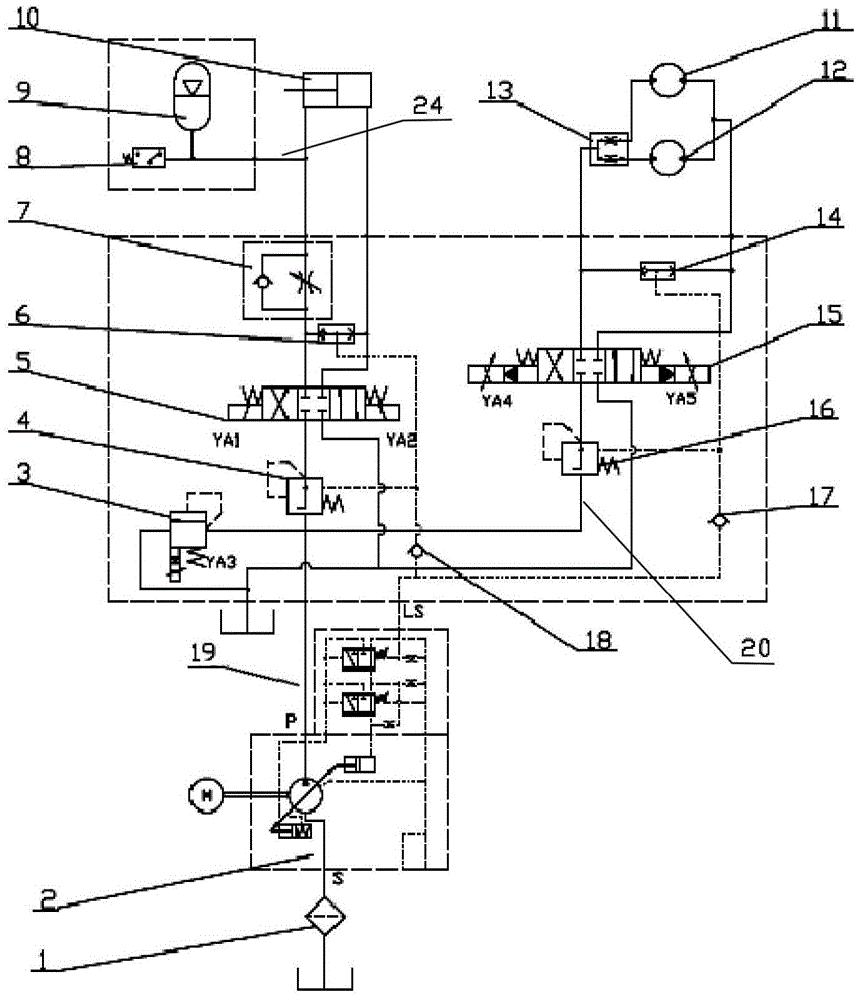

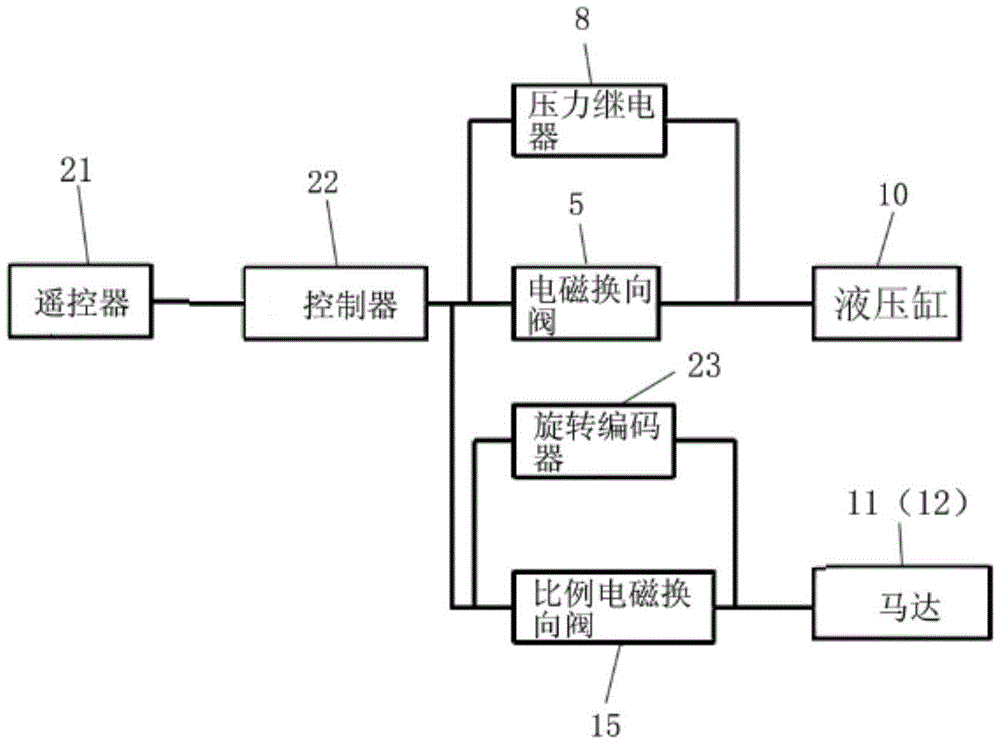

[0028] refer to Figure 2 to Figure 3 , according to an embodiment of the present invention, the provided hydraulic control system for the pipe feeder of the mixed explosive vehicle includes a hydraulic pump 2, a hydraulic cylinder 10, an electromagnetic reversing valve 5, two motors 11 and 12, a proportional electromagnetic reversing Directional valve 15, proportional electromagnetic overflow valve 3 and controller 22.

[0029] The hydraulic pump 2 is connected to the hydraulic cylinder 10 through the first oil passage 19, and a filter 1 can also be arranged between the hydraulic pump 2 and the oil tank. The hydraulic pump 2 may be a load sensitive variable hydraulic pump.

[0030] The electromagnetic reversing valve 5 is connected between the hydraulic pump 2 and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com