Train mounted lifting forklift device

A technology for lifting forklifts and trucks, applied in the direction of lifting devices, etc., to achieve the effects of simple control method, stepless adjustment of height difference, and improved loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

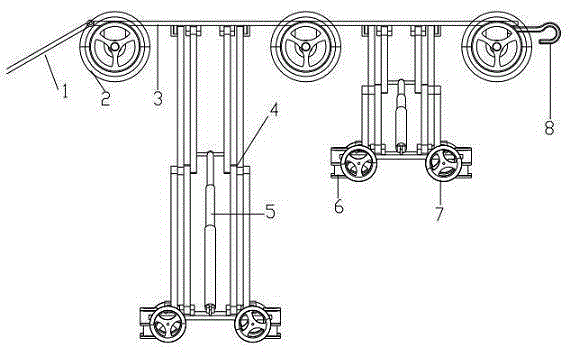

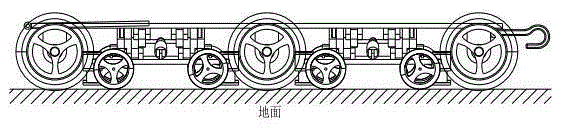

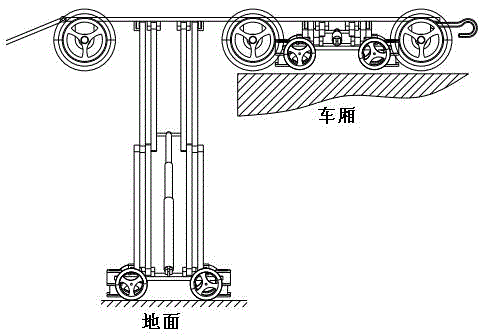

[0018] The specific embodiment of the present invention is as shown in the accompanying drawings.

[0019] Figure 1 is a structural schematic diagram of this embodiment, a train on-board forklift device in this embodiment includes a scissor lift mechanism 4, a transition plate 1, a lifting plate 3, a large roller 2, a large hydraulic cylinder 5, and a small hydraulic cylinder 6. Small roller 7 and fixed hook 8. There are three pairs of large rollers 2, which are respectively installed at the front, middle and rear of the lift plate 3; two sets of scissor lift mechanisms 4 are respectively installed on both sides of the middle and large rollers; the large hydraulic cylinder 5 is installed on the scissor lift The lifting mechanism 4 is used to lift the lifting plate 3; the lower part of the scissor lifting mechanism 4 is equipped with two pairs of small rollers 7 and a small hydraulic cylinder 6; when the small rollers 7 are not working, the small hydraulic cylinder 6 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com