Spinning Technology with Large Draft on Spinning Frame

A technology of spinning frame and large draft, applied in spinning frame, drafting equipment, textile and paper making, etc., can solve the problems of frequent defect improvement, middle roller prone to torsional vibration, occasional defect deterioration, etc. Wide range of suitable spinning linear density, large total draft ratio of spun yarn and reasonable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

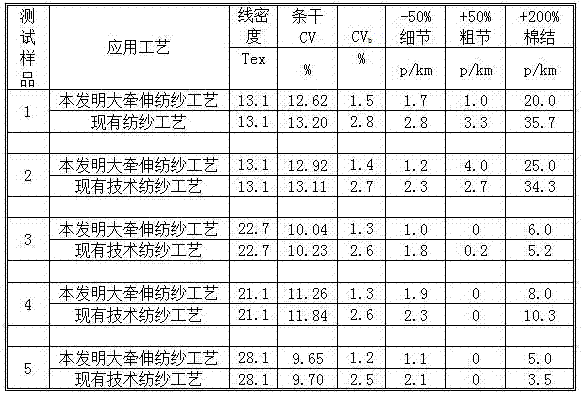

Examples

Embodiment 1

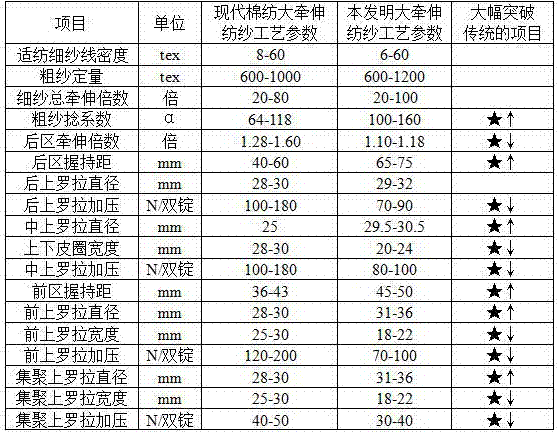

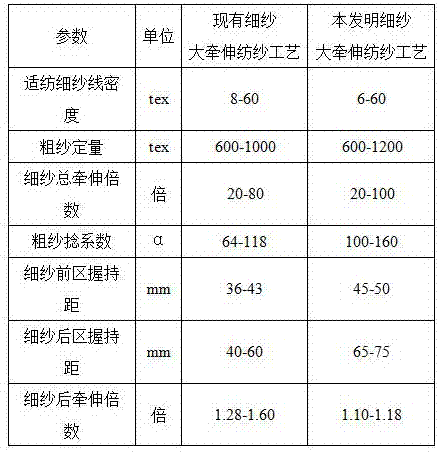

[0022] Embodiment 1, spinning long-staple cotton pure cotton combed yarn:

[0023] The large draft spinning process of the spinning frame of the present invention is suitable for the roving weight quantitative and large draft spinning process of the spun yarn, a roving is fed into the drafting system of the spinning frame, the spun yarn has a linear density of 6tex, and the roving is fed quantitatively 600tex, after drafting and twisting, it is wound onto the bobbin to form a yarn; the metric twist coefficient of the roving is 140, the maximum holding distance of the spun yarn front area is 46 mm, the maximum holding distance of the spun yarn rear area is 70 mm and the small rear area is drawn The elongation factor is 1.10 times.

[0024] The high-draft spinning process of the spinning frame of the present invention has a creative breakthrough in the technical configuration of the large twist coefficient of the roving, the large holding distance of the front and rear areas of ...

Embodiment 2

[0025] Embodiment 2, spin fine-staple cotton pure cotton carded yarn:

[0026] The large draft spinning process of the spinning frame of the present invention is suitable for the roving weight quantitative and large draft spinning process of the spun yarn. One roving is fed into the drafting system of the spinning frame, and the spun yarn has a linear density of 59.1tex and is fed into the roving. Quantitative 1200tex, after drafting and twisting, it is wound onto the bobbin to form yarn; the metric twist coefficient of the roving is 160, the maximum holding distance of the spun yarn front area is 45 mm, the maximum holding distance of the spun yarn rear area is 65 mm and the small rear area The draft ratio is 1.12 times.

[0027] The high-draft spinning process of the spinning frame of the present invention has a creative breakthrough in the technical configuration of the large twist coefficient of the roving, the large holding distance of the front and rear areas of the spun...

Embodiment 3

[0028] Embodiment 3, spinning polyester-cotton blended yarn:

[0029]The large draft spinning process of the spinning frame of the present invention is suitable for the roving weight quantitative and large draft spinning process of the spun yarn, one roving is fed into the drafting system of the spinning frame, the spun yarn has a linear density of 9.8tex, and the roving is fed Quantitative 600tex, after drafting and twisting, it is wound onto the bobbin to form a yarn; the metric twist coefficient of the roving is 100, the maximum holding distance of the spun yarn front area is 48 mm, the maximum holding distance of the spun yarn rear area is 70 mm and the small rear area The draft ratio is 1.18 times.

[0030] The high-draft spinning process of the spinning frame of the present invention has a creative breakthrough in the technical configuration of the large twist coefficient of the roving, the large holding distance of the front and rear areas of the spun yarn, and the smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com