A laundry ball with cleaning function and its manufacturing method

A production method and technology of laundry balls, which are applied to other washing machines, washing devices, household appliances, etc., can solve the problems of lack of effect, inability to truly achieve the fundamental effect of removing dirt, and single washing effect, so as to expand new methods and improve laundry The effect of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

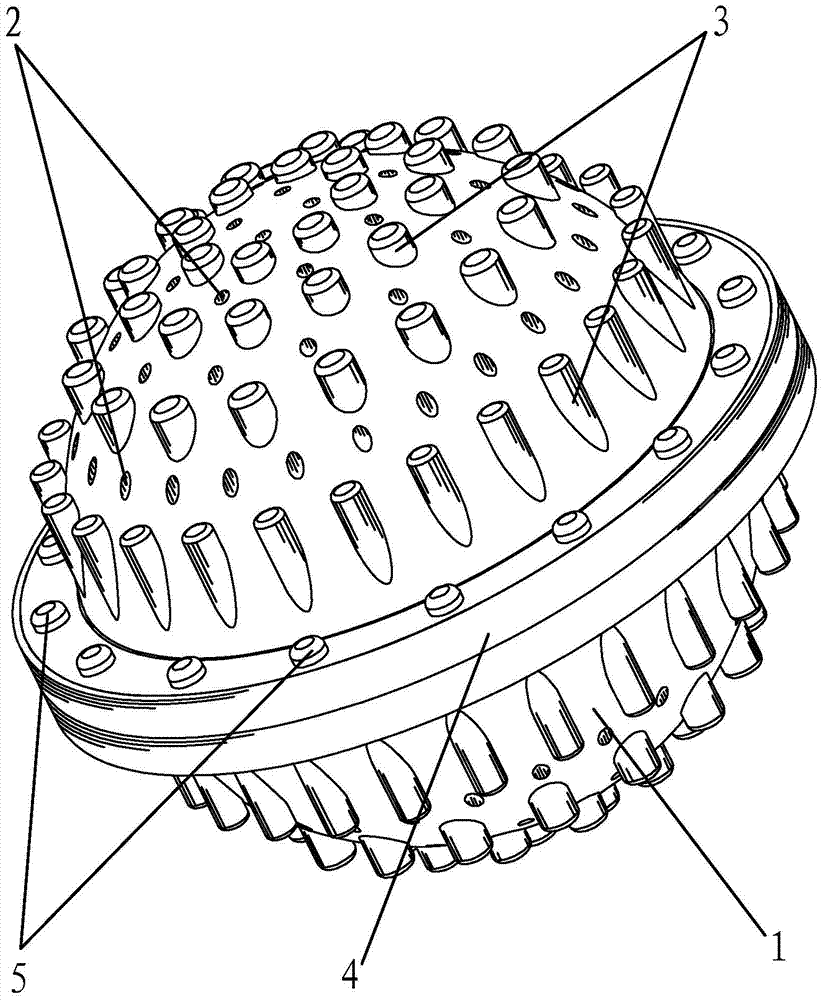

[0047] Such as figure 1 As shown, the laundry ball with cleaning function includes a spherical shell, which is composed of two hemispherical shells 1, and the diameter of the hemispherical shell 1 is 10 cm. The round edge of the hemispherical shell 1 is provided with a flange edge 4, and 16 melt-molding pins 5 are arranged on the flange edge 4, and the center distance of each melt-molding pin 5 is 16 mm. The protruding plastic is dissolved by electric welding to form the melting pin 5 , that is, the flanges of the two hemispherical shells 1 are fitted and fixed along the 4 by melting the plastic.

[0048] There is a spherical cavity inside the spherical shell, and several solid particles are placed in the spherical cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com