Lumber drying kiln

A technology for drying furnaces and wood, applied in drying, dryers, heating devices, etc., can solve problems such as boilers or pipelines are easy to form scale, reduce boiler thermal efficiency, and air thermal conductivity is small, so as to save drying time , cost reduction, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

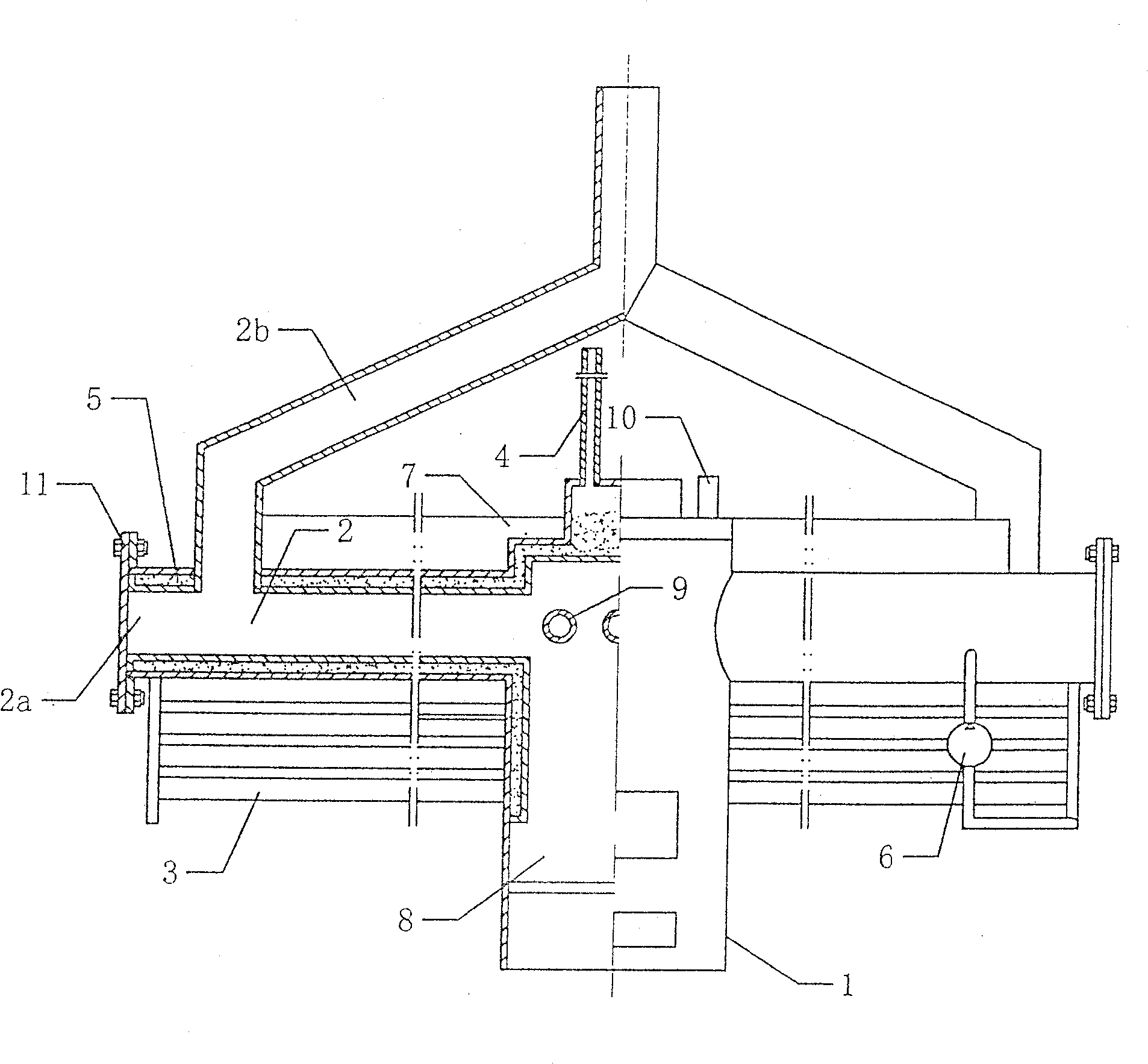

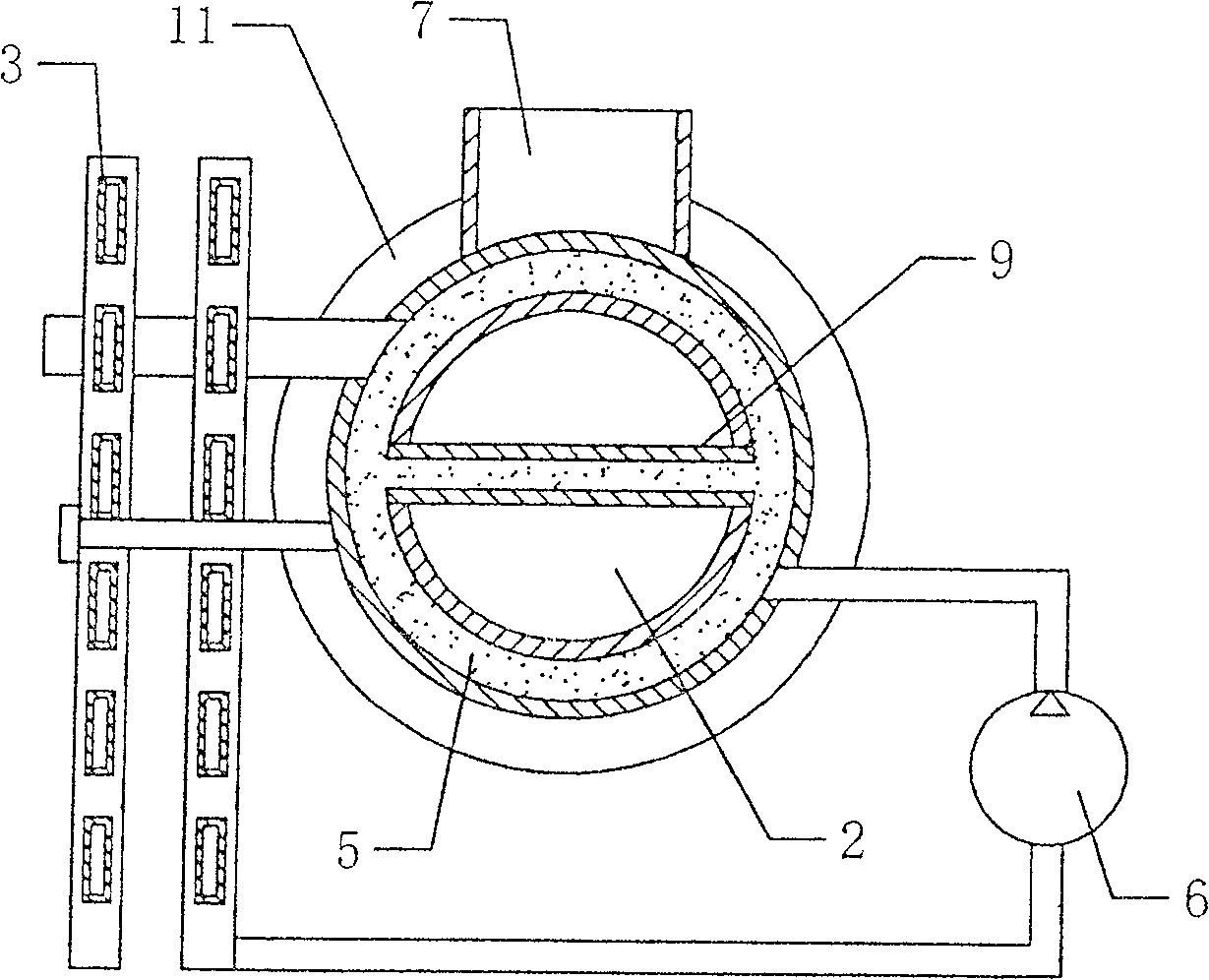

[0017] Such as figure 1 and figure 2 As shown, the wood drying furnace includes a furnace body 1, a flue 2 communicated with the combustion chamber 8 and the smoke outlet of the furnace body 1, the flue 2 is fixed on the outside of the furnace body 1, and the The flue 2 and the furnace body 1 are provided with a heat-conducting oil interlayer 5 connected to each other, and the heat-conducting oil interlayer 5 is provided with an expansion oil pipe 4 communicating with the atmosphere, which is used to circulate the heat-conducting oil in the heat-conducting oil interlayer 5. pump6.

[0018] The flue 2 includes a main flue 2a extending horizontally to both sides of the furnace body, an auxiliary flue 2b connected between the end of the main flue 2a and the smoke outlet, and the heat transfer oil interlayer 5 Wrapped on the outside of the main flue 2a and the furnace body 1, the main flue 2a can be set according to the size of the drying kiln. In this way, the heat transfer oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com