Mold with heat-insulating function

A mold and function technology, applied in the field of mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

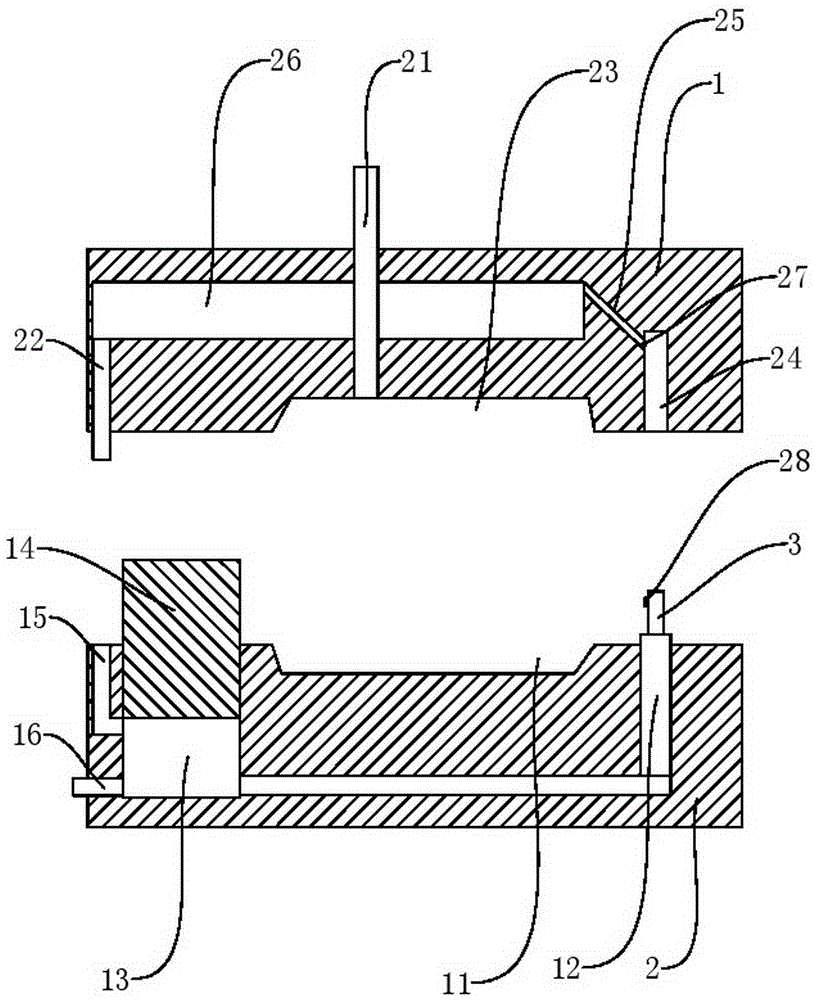

[0029] Basic as attached figure 1 Shown: mold with thermal insulation function, including:

[0030] The lower mold 2, the upper surface of the lower mold 2 is provided with a first molded surface 11, the surrounding of the first molded surface 11 is provided with a lower blind hole, the lower mold 2 is provided with a hydraulic chamber 13 filled with water, and the hydraulic chamber 13 is connected to the lower mold The blind hole communicates, the diameter of the cross section of the hydraulic chamber 13 is greater than the diameter of the cross section of the lower blind hole, the hydraulic chamber 13 is provided with a piston 14 slidingly connected with the hydraulic chamber 13, the piston 14 is exposed from the upper surface of the lower die 2, and the lower die 2 A liquid inlet 15 is provided on the top, and a one-way valve is provided in the liquid inlet 15. A drain pipe 16 is also provided on the lower mold 2. A drain valve is provided on the drain pipe 16. The drain pi...

Embodiment 2

[0034] Compared with Embodiment 1, the only difference is that the upper column 3 is in the shape of a truncated cone with a thick top and a thin bottom, the distance between the upper blind holes 24 is 5-10 mm, and the distance between the lower blind holes is the same as that of the upper blind holes 24. same.

Embodiment 3

[0036] Compared with Embodiment 1, the only difference is that there are at least two hydraulic chambers 13, and the hydraulic chambers 13 are all communicated with the lower blind hole, and the diameters of the cross-sections of all hydraulic chambers 13 are larger than the diameter of the lower blind hole cross-section, and the hydraulic pressure Pistons 14 that are slidably connected to the hydraulic chamber 13 are provided on the chambers 13 , and all of the pistons 14 are exposed from the upper surface of the lower mold 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com