Bridge plug

A technology of bridge plug and central hole, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., which can solve problems affecting the accuracy of test data, increasing economic costs, and easy to block bridge plugs, etc., to achieve The effect of shortening the spraying time, reducing the liquid flow displacement and preventing the jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

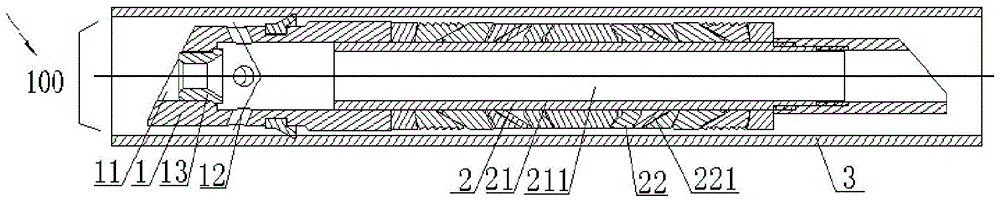

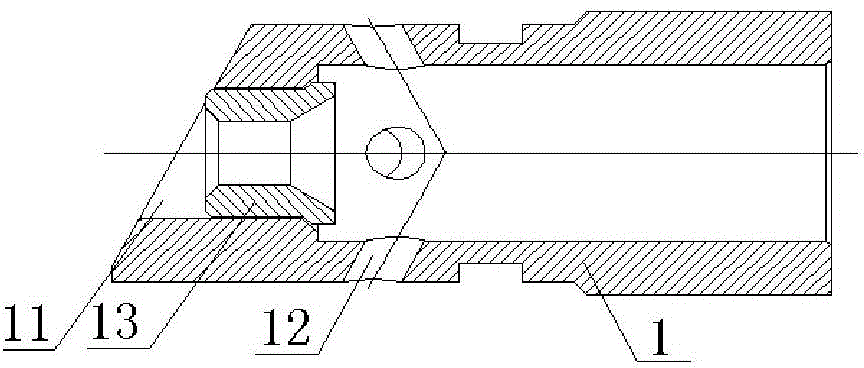

[0022] see figure 1 , which is a cross-sectional view of the overall structure of the bridge plug of the present invention. As shown in the figure, the bridge plug 100 includes a joint assembly 1 . The center of the joint assembly 1 is machined into a central hole 11 with a large diameter. Wherein, a stopper assembly 13 is provided inside the large-diameter center hole 11 to reduce the displacement of the bridge plug 100 during pumping. Wherein, the outer diameter of the large-diameter center hole 11 and the stopper assembly 13 is an interference fit.

[0023] The bridge plug 100 also includes a central pipe unit 2 communicating with the large-diameter central hole 11 in the joint assembly 1 .

[0024] The base pipe unit 2 includes a base pipe assembly 21 . In a preferred embodiment, the inner diameter of the inner central hole 211 of the central pipe assembly 21 is sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com