Composite load-bearing detection cable

A detection cable and composite technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of single function of load-bearing detection cables, achieve the effect of smooth and wear-resistant surface, prevent resistance, and avoid the effect of service life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

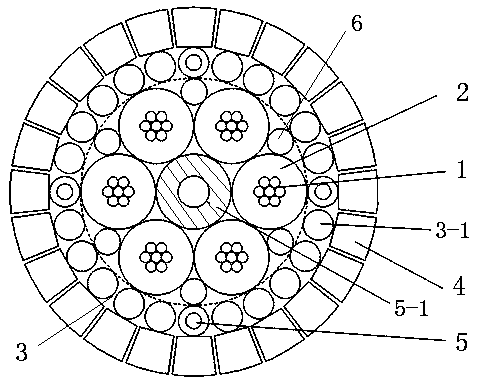

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] see figure 1 , the present invention includes a central steel pipe 5-1 and multiple sets of copper strands 1 surrounding it, the outer layers of each set of copper strands 1 are respectively surrounded by an insulating layer 2 (constituting a single-core cable, and each single-core cable is mutually twisted close), the outer layer of the insulating layer 2 is surrounded by an inner steel wire armor layer 3, and the inner steel wire armor layer 3 is surrounded by a group of steel wires 3-1 with a circular cross section and a hollow steel pipe 5 to form a closed An annular shape, the outer steel wire armor layer 3 is covered with an outer steel wire armor layer 5, and the outer steel wire armor layer 4 is surrounded by a group of steel wires with fan-shaped cross-sections to form a closed annular ring. The composite load-bearing detection cable of the invention has reasonable structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com