Postoperative disinfecting and cleaning system for anesthesiology department

A cleaning system and anesthesiology technology, applied in the field of medical anesthesiology, can solve problems such as blood stains, safety hazards, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

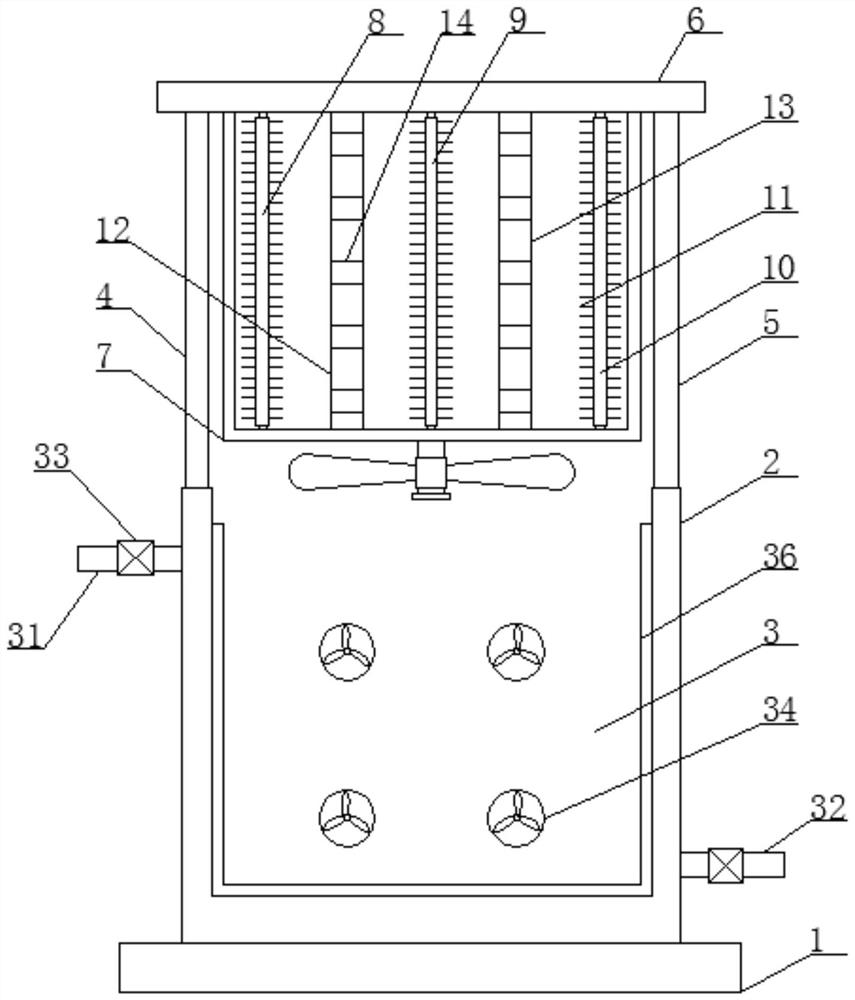

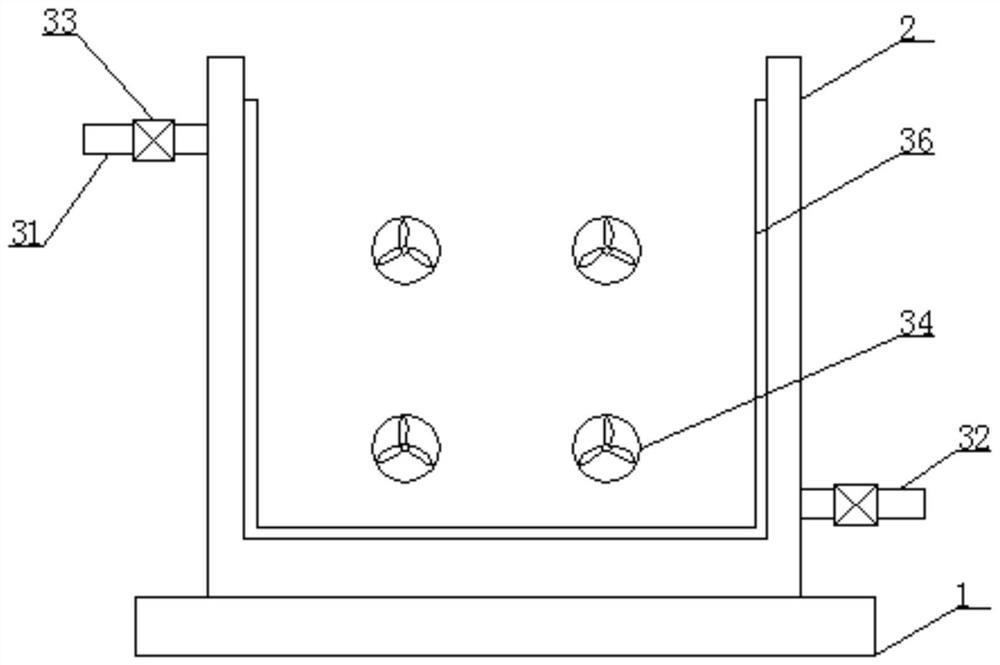

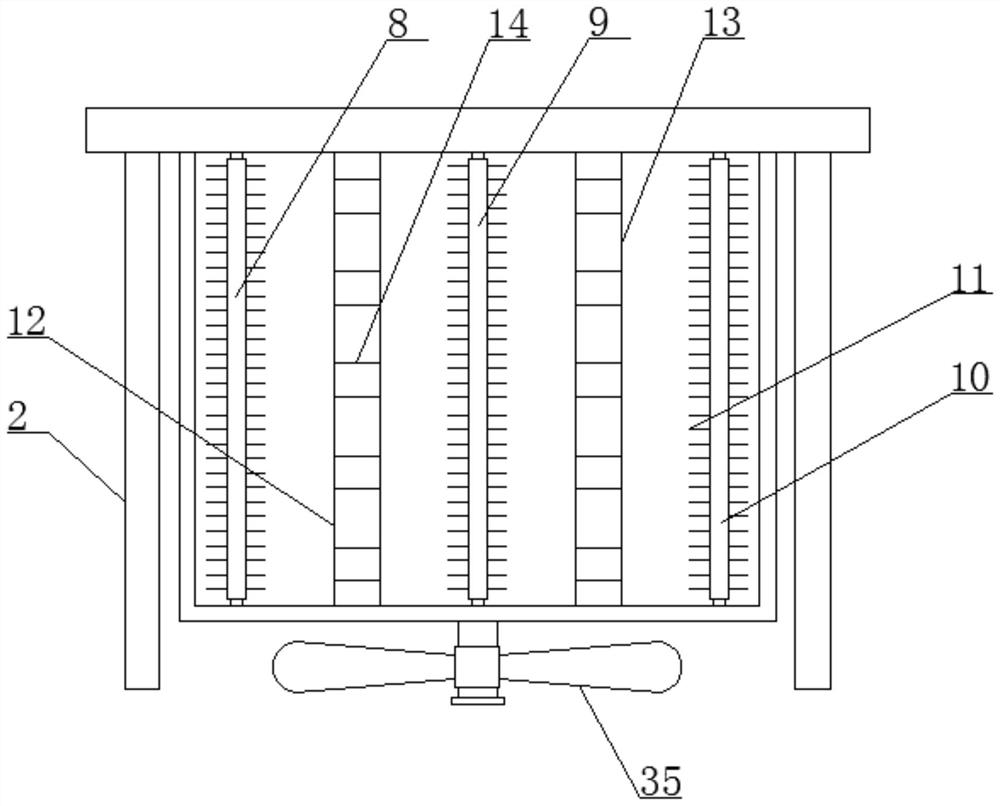

[0022] Such as Figure 1-8 As shown, the anesthesiology postoperative disinfection and cleaning system according to the embodiment of the present invention includes a bottom plate 1 and a box body 2 located at the top of the bottom plate 1, the box body 2 is a cavity structure with an open top, and the box body 2 A cleaning chamber 3 is provided inside, and side panels one 4 and side panels two 5 are arranged symmetrically on both sides of the top of the box body 2, and the tops of the side panels one 4 and side panels two 5 are provided with transverse The cover plate 6 provided, the bottom end of the cover plate 6 is provided with a frame 7 that matches the cleaning chamber 3, and the frame 7 is provided with a rotating shaft 8, a rotating shaft 9 and a rotating shaft 9 from left to right. The rotating shaft three 10, the rotating shaft one 8, the rotating shaft two 9 and the rotating shaft three 10 are all provided with bristles 11 matched therewith, and are located in the ...

Embodiment 2

[0027] Such as Figure 1-8 As shown, on the vertical bar 21 and at the top end of the compression spring 25, there is a laterally arranged limiting horizontal plate 37, and the bristles 11 are connected to the first rotating shaft 8 and the second rotating shaft 9 through the connecting piece. Connected with the rotating shaft three 10, rubber pads 38 are provided on the sides of the first fixed plate 15 and the second fixed plate 16 that are close to each other, and several evenly distributed anti-slip lines are provided on the rubber pads 38 . Through the design of the limiting horizontal plate 37, the quick return of the vertical bar 21 can be improved, and the rubber pad 38 can prevent the contact between the first fixed plate 15 and the second fixed plate 16 and the medical equipment to cause abrasion.

Embodiment 3

[0029] Such as Figure 1-8As shown, the upper opening of the box body 2 is provided with a stroke groove 39 that matches the side plate one 4 and the side plate two 5, and the bottom end in the stroke groove 39 is provided with a stroke groove that matches the side plate one. 4. The electric telescopic rod 40 connected to the side plate 2 5, the bottom end of the cover plate 6 is provided with a gasket matching the box body 2, the gasket is a waterproof sealing ring, and the bottom plate 1 A number of evenly distributed fixing holes 41 are opened on the top, and the bottom end of the bottom plate 1 is provided with a non-slip rubber pad. Through the cooperation of the electric telescopic rod 40 and the stroke groove 39 , the side plate one 4 and the side plate two 5 can be extended to the stroke groove 39 to realize the closure of the cover plate 6 and the box body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com