Mining anchor rod

A bolt and mine-used technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problem of low prestress of bolts, easy rotation or displacement of arched backing plates, tensile strength and pull-out resistance Poor and other problems, to achieve the effect of increasing prestress, preventing rotation or displacement, and improving tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

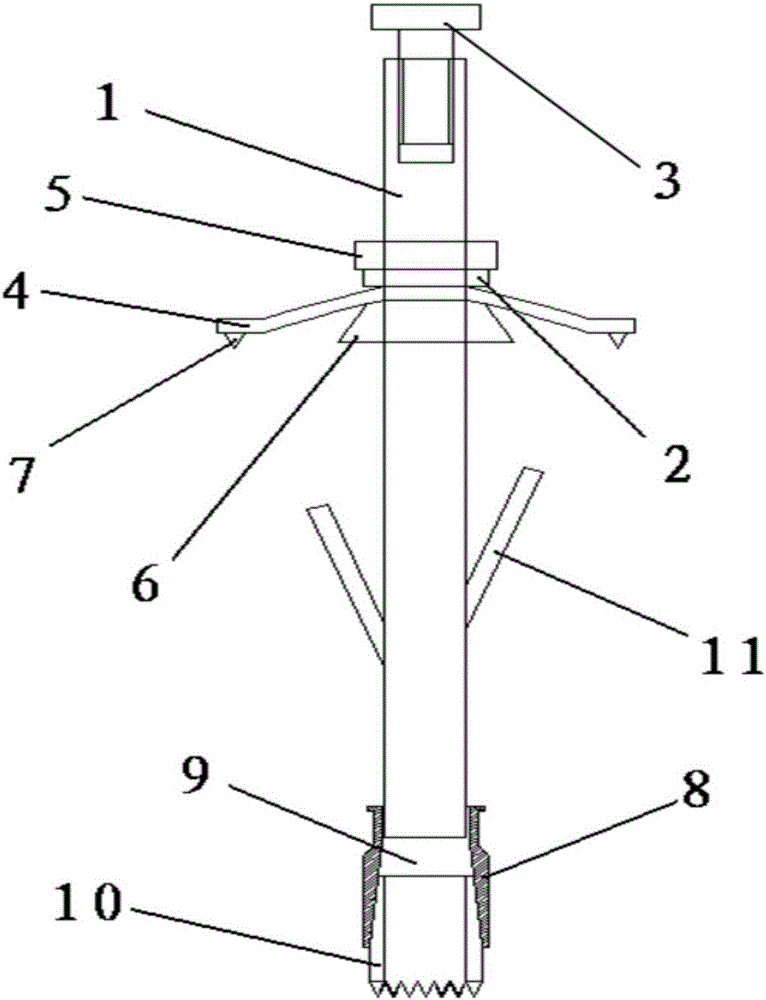

[0017] Such as figure 1 In the illustrated embodiment, a mine bolt includes a screw rod body 1, the front and rear ends of the screw rod body 1 are respectively provided with an anchor head 2 and a bolt 3, and the screw rod body 1 is provided with a position close to the bolt 3 An arched backing plate 4, the spiral rod body 1 on the upper and lower sides of the arched backing plate 4 is provided with a fixing nut 5 and a grouting plug 6 respectively, and a plurality of tooth heads 7 are provided on one side of the arched backing plate 4 The anchor head includes an expansion shell 8, the expansion shell 8 is provided with a through hole 9 in the axial direction, and the lower end of the through hole 9 is in the shape of a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com