Cycloid rotor pump of sewing machine

A cycloidal rotor pump and sewing machine technology, applied in the direction of rotary piston pumps, pumps, lubricating pumps, etc., can solve the problems of inability to achieve fast and effective lubrication, troublesome suction and discharge of lubricating oil, and affecting the use of sewing machines, etc., to achieve a compact structure , Sufficient time for oil absorption and oil discharge, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

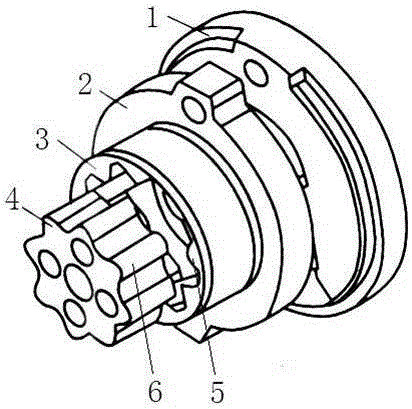

[0014] Such as figure 1 As shown, a sewing machine cycloidal rotor pump includes a base 1, a pump body 2, an outer rotor 3 and an inner rotor 4, the base 1 adopts a circular base, the pump body 2 is hinged together by screws, and the outer rotor 3 It is arranged on the pump body 2, and the outer rotor 3 can move freely in the pump body 2. The inner teeth 5 are arranged inside the outer rotor 3, and the outer teeth 6 are arranged outside the inner rotor 4. The inner teeth 5 and the outer teeth 6 Partial meshing is possible, and the number of 5 internal teeth is one less than the number of 6 external teeth. The base 1 is made of stainless steel. The inner side of the outer rotor 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com