Patents

Literature

34results about How to "Full oil absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Buoyancy driving device based on marine environment parameter adjusting

ActiveCN109591988AEasy to adjustQuantitative adjustmentBuoysUnderwater vesselsMathematical modelEngineering

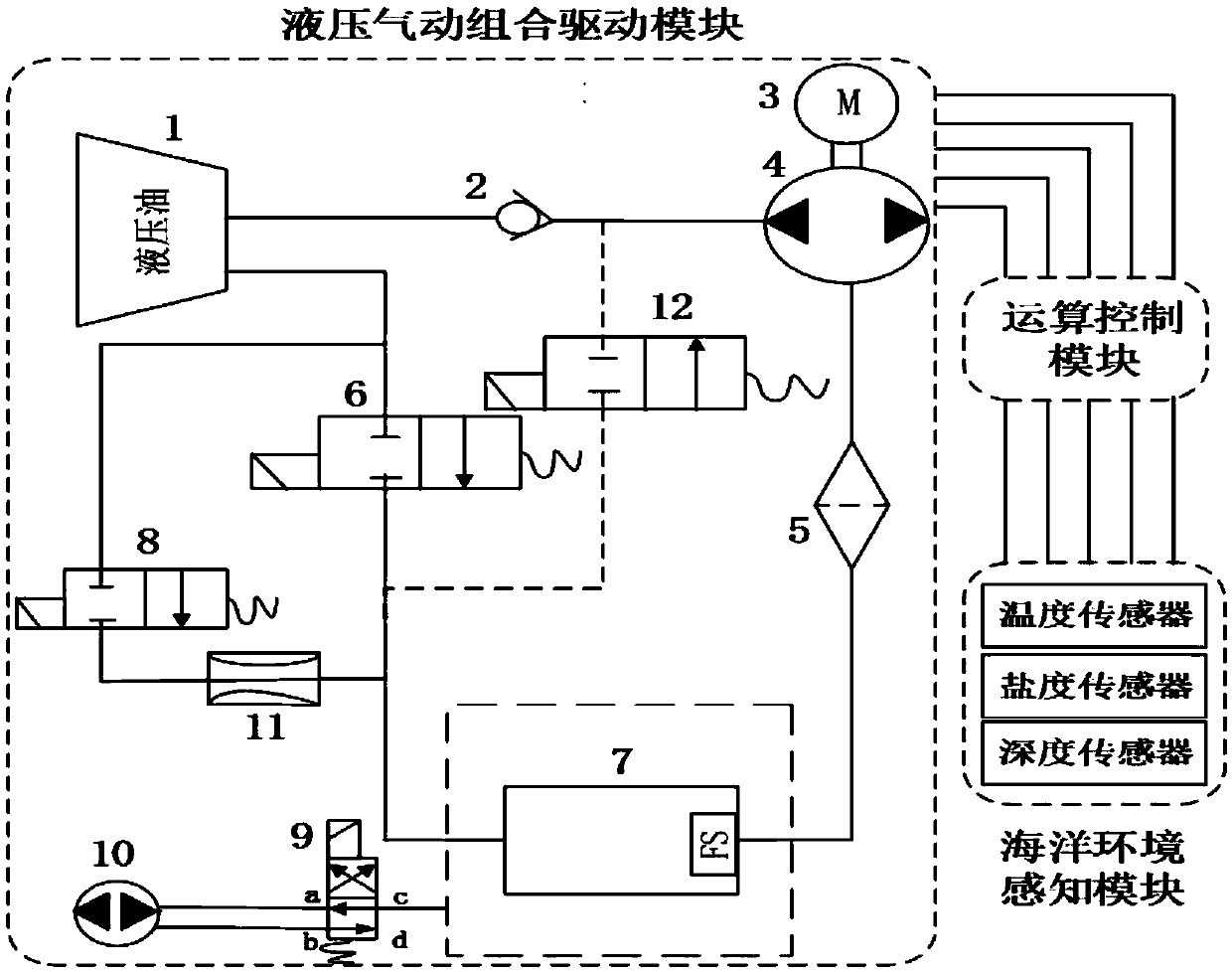

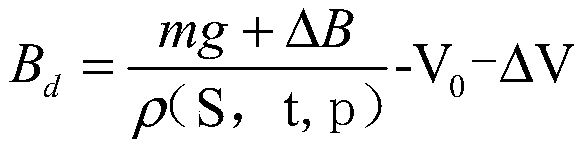

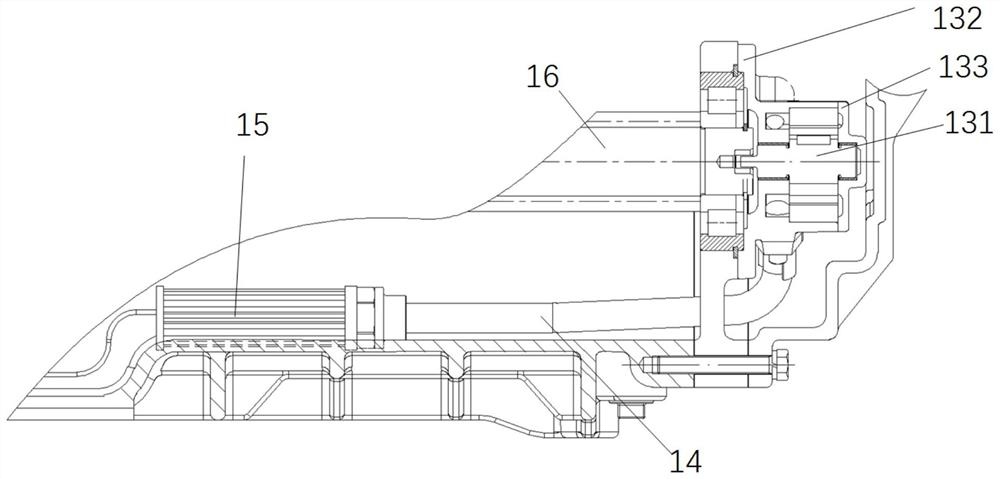

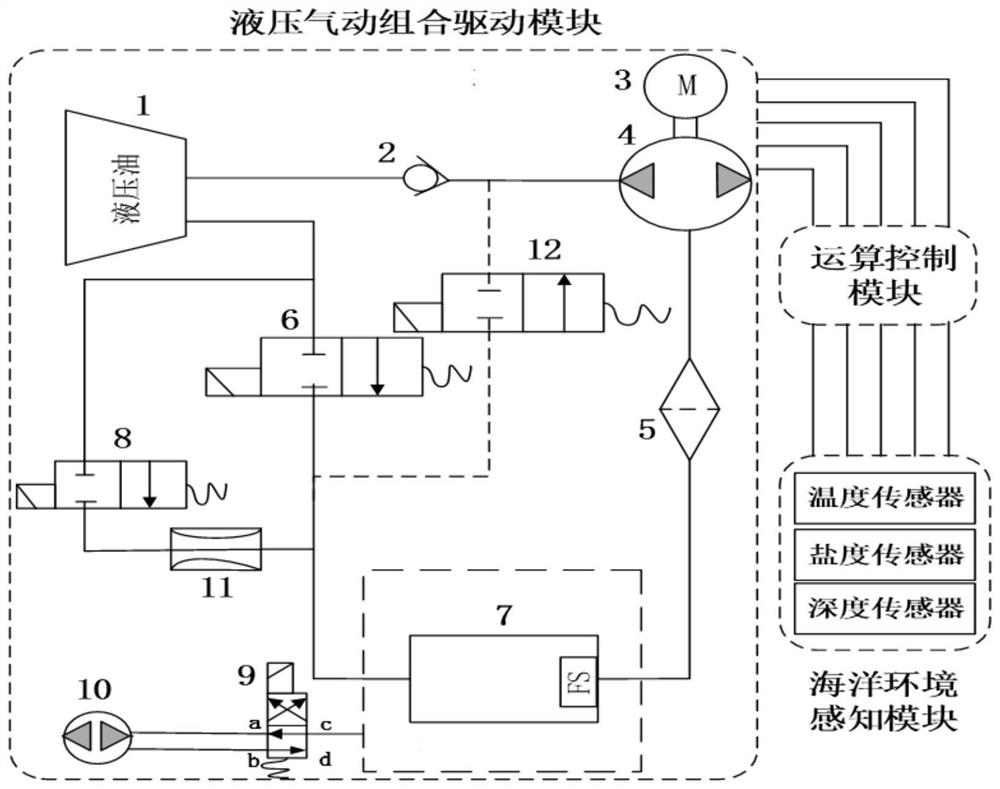

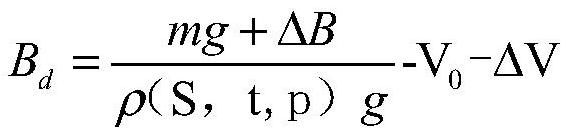

The invention provides a buoyancy driving device based on marine environment parameter adjusting and belongs to the field of ocean engineering. The buoyancy driving device based on marine environmentparameter adjusting can accurately and quantitatively adjust a buoyancy quantity. The buoyancy driving device based on marine environment parameter adjusting comprises a hydraulic and pneumatic combined driving module, a marine environment sensing module and a computing control module, wherein each sensor in the marine environment sensing module can measure parameters, such as temperature, salinity and depth, of seawater in real time; the computing control module can calculate a buoyancy quantity needing to be adjusted by collecting measuring data and combining a system motion mathematical model and a seawater density mathematical model which are preset in a built-in program of the computing control module; and then the computing control module re-controls the action of electrical equipment in the hydraulic and pneumatic combined driving module to adjust the buoyancy. According to the buoyancy driving device based on marine environment parameter adjusting, the integration degree is high, accurate and quantitative buoyancy control can be realized according to the change of the environment parameters, and the system is reliable.

Owner:CSIC NO 710 RES & DEV INST

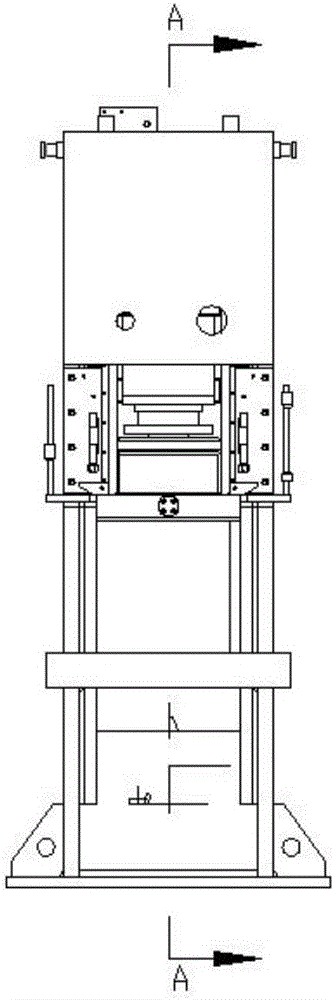

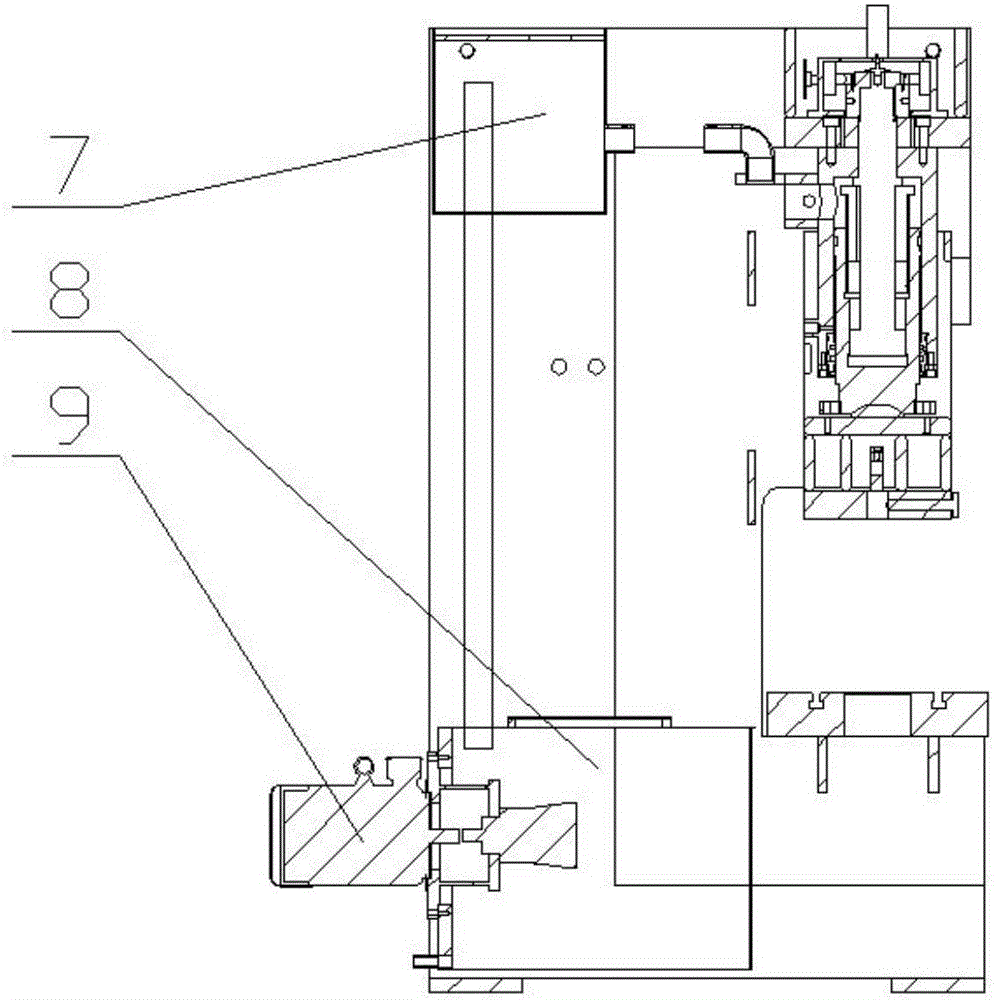

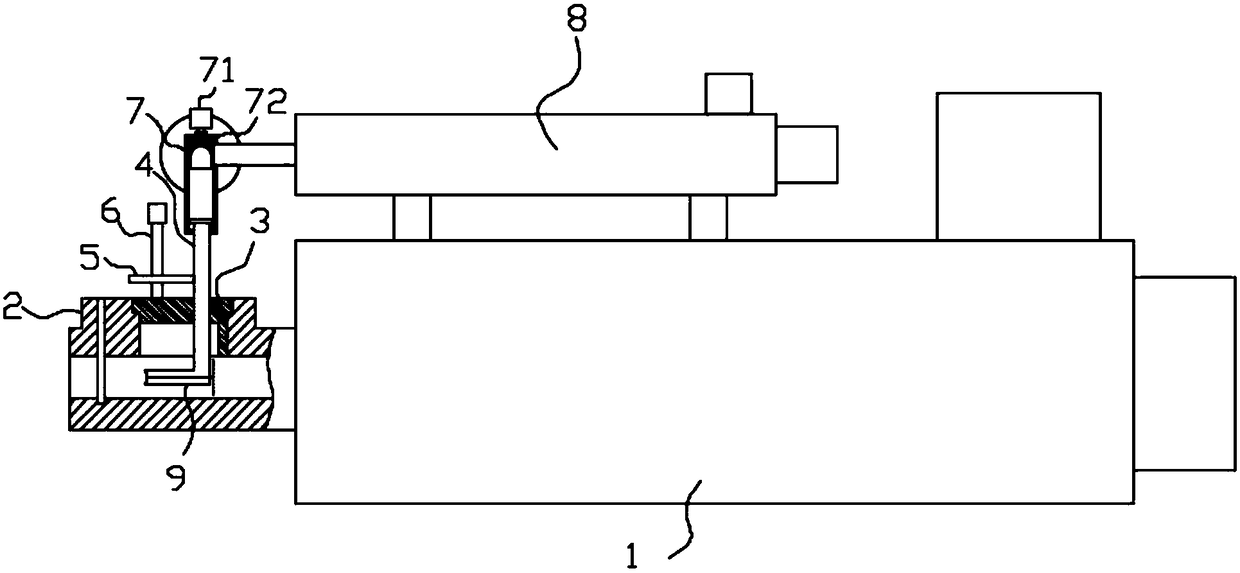

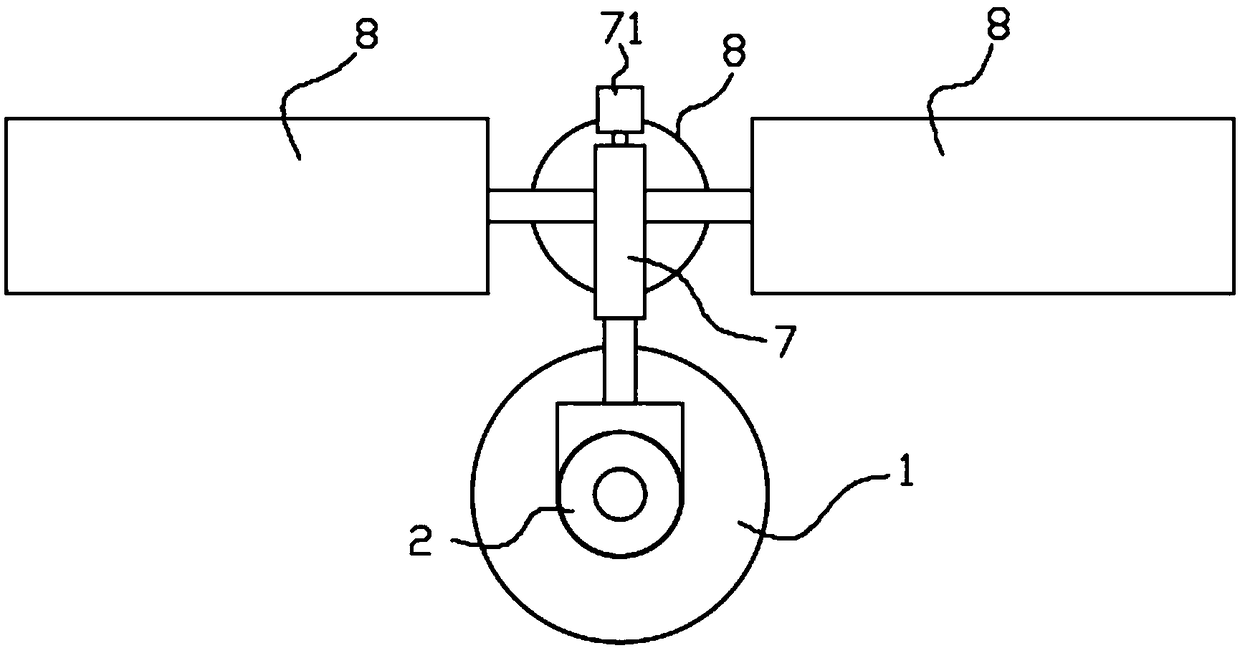

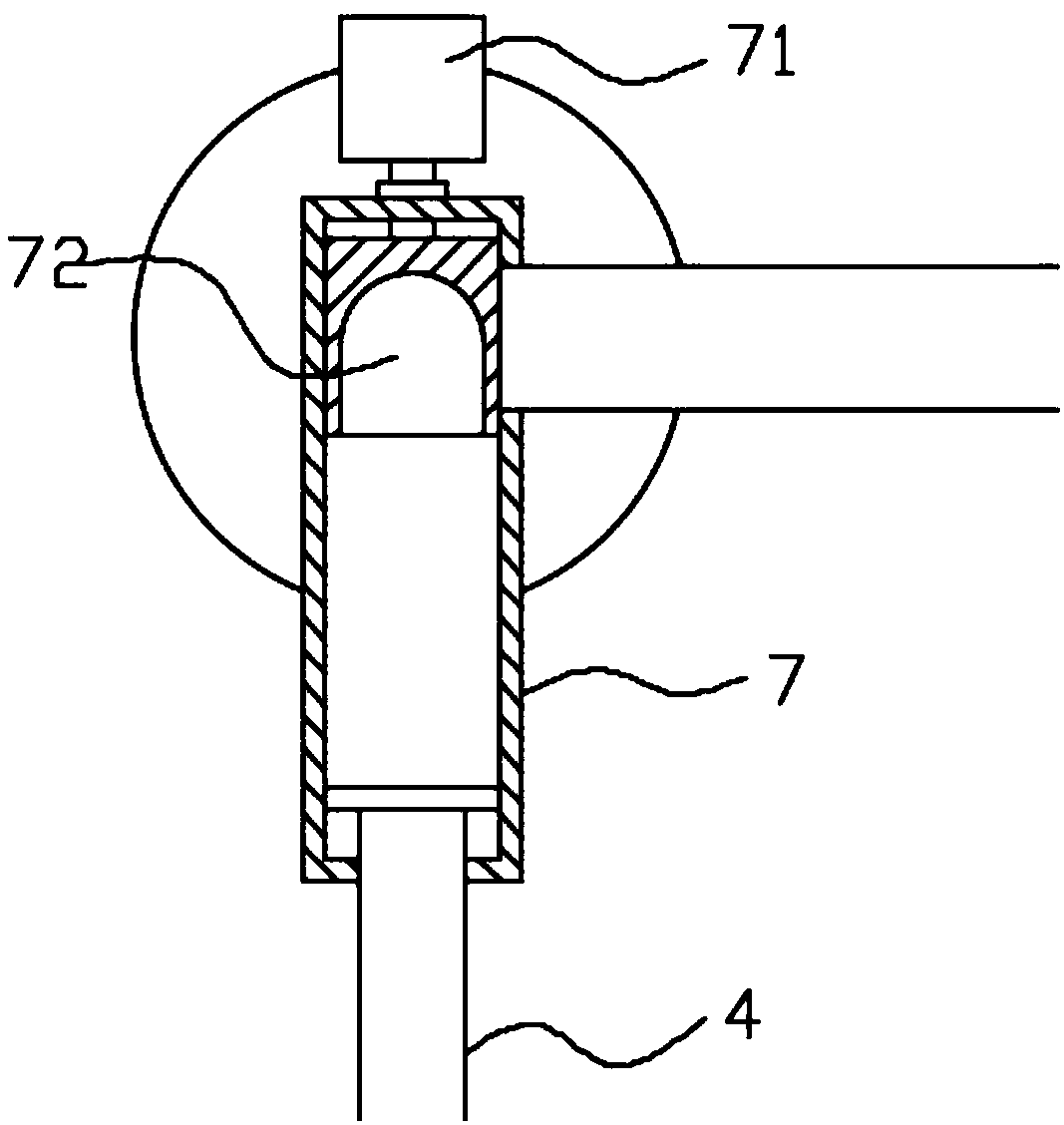

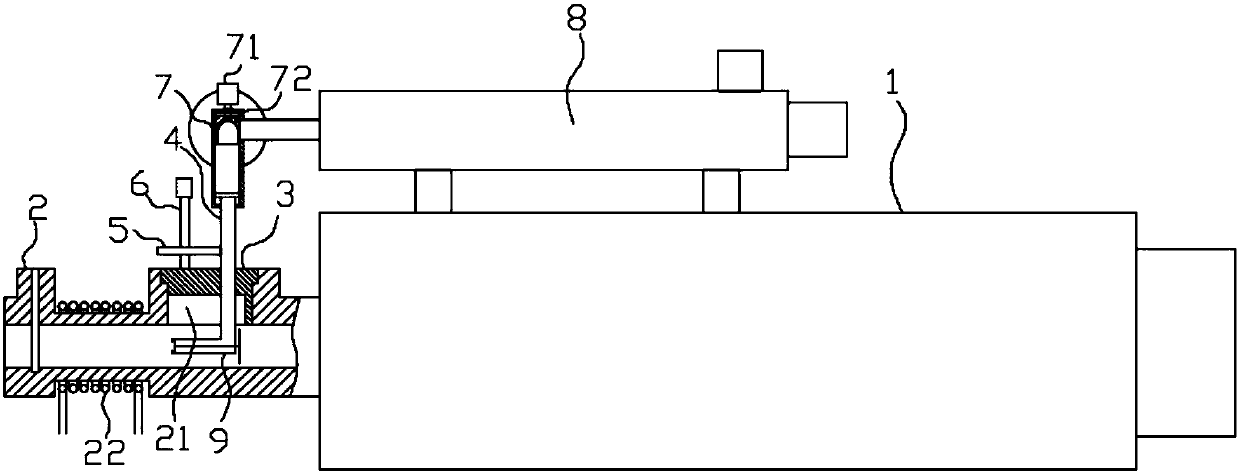

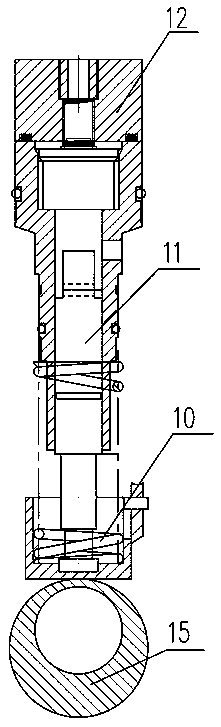

Stroke regulation built-in precise fast press machine, and oil cylinder and use method thereof

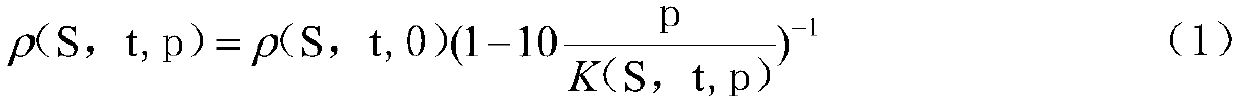

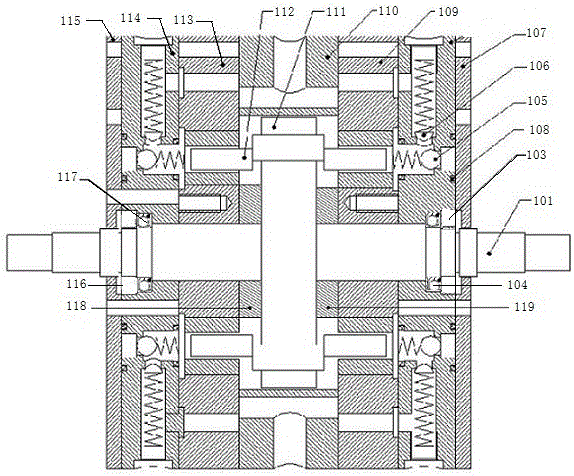

The invention discloses a stroke regulation built-in precise fast press machine, and an oil cylinder and a use method thereof, belongs to the field of a hydraulic press machine, and solves the problems of low production efficiency, high cost and complicated structure of a slide block regulating mechanism of the existing hydraulic press machine. The oil cylinder provided by the invention comprises a main cylinder piston rod and a main cylinder body, wherein one end of the main cylinder piston rod extends into the main cylinder body; one end extending into the main cylinder body is provided with a cavity; a regulating screw nut is arranged at the upper part of the inner wall of the cavity; the regulating screw nut and the inner wall of the cavity are connected through screw threads; a regulating screw rod is also arranged in the cavity; the lower end of the regulating screw rod extends into the cavity; the middle end passes through the regulating screw nut; the upper end extends out of the main cylinder body; the upper end, extending out of the main cylinder body, of the regulating screw rod is fixedly provided with a worm wheel; the middle end, penetrating through the regulating screw nut, of the regulating screw rod is provided with a key slot; a guide key is arranged on the corresponding regulating screw nut. The press machine, the oil cylinder and the use method have the advantages that the cost can be reduced; the production efficiency is improved; the applicability to various processing processes can be realized.

Owner:YANGZHOU ENG MACHINERY CO LTD

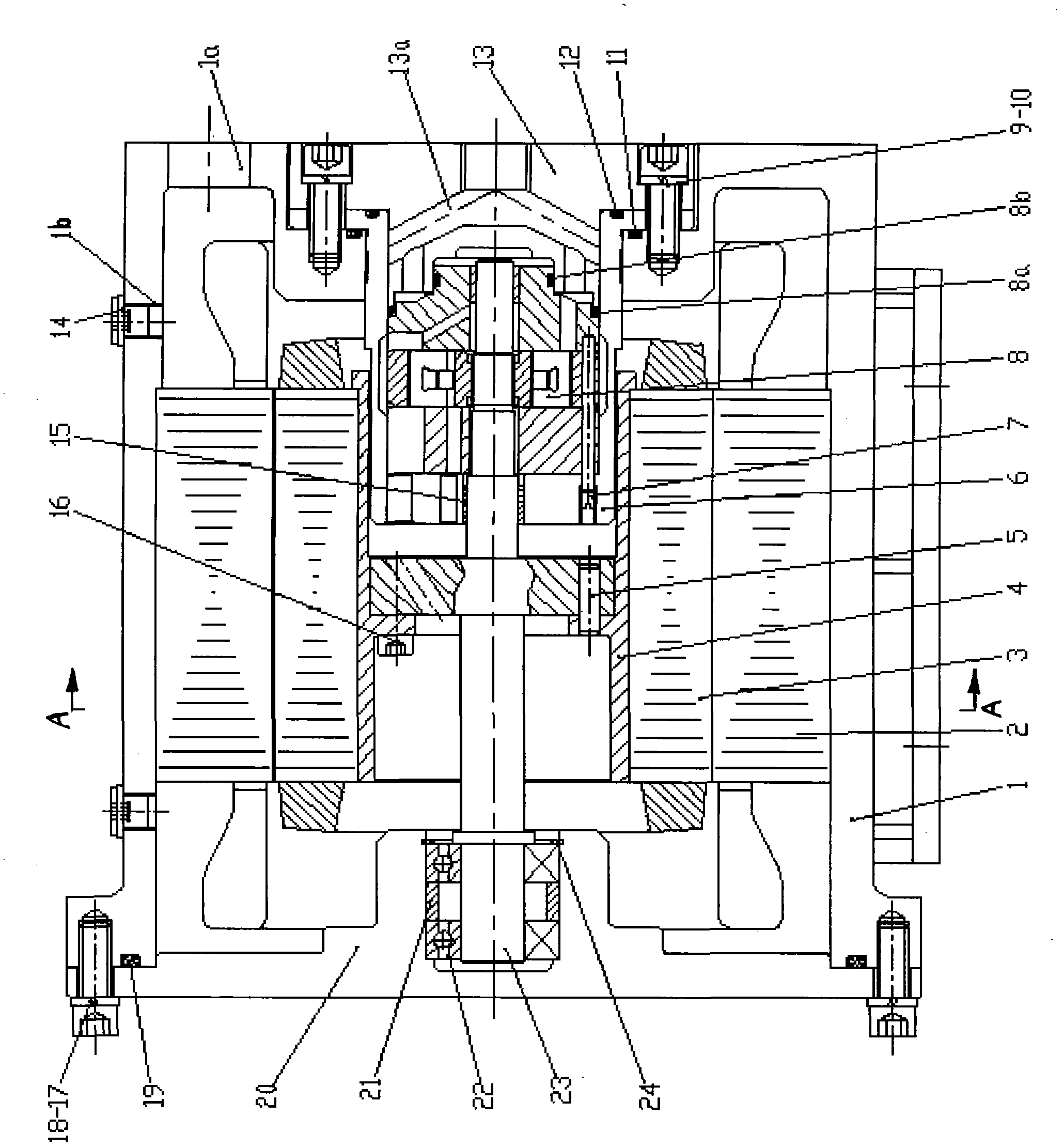

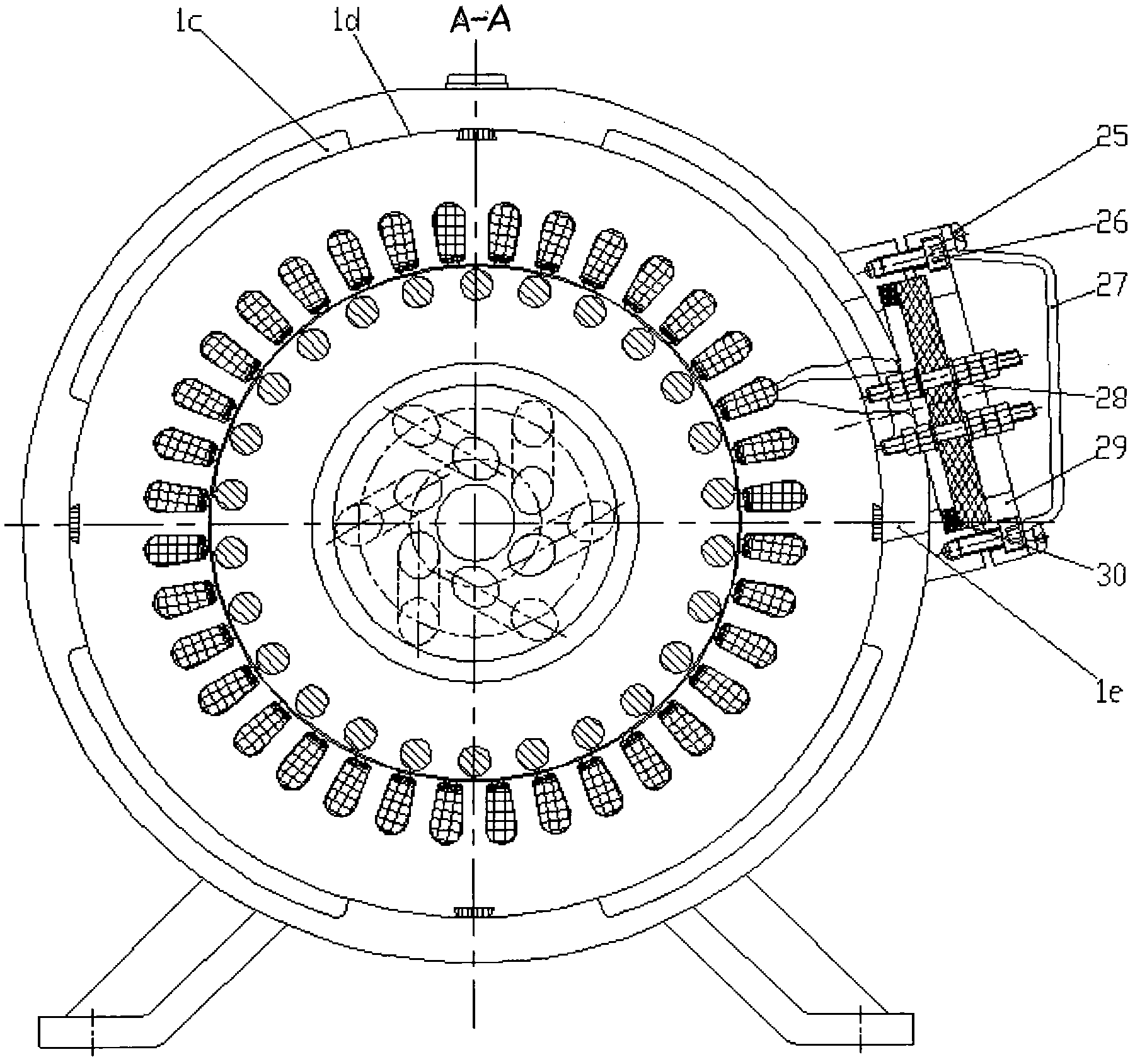

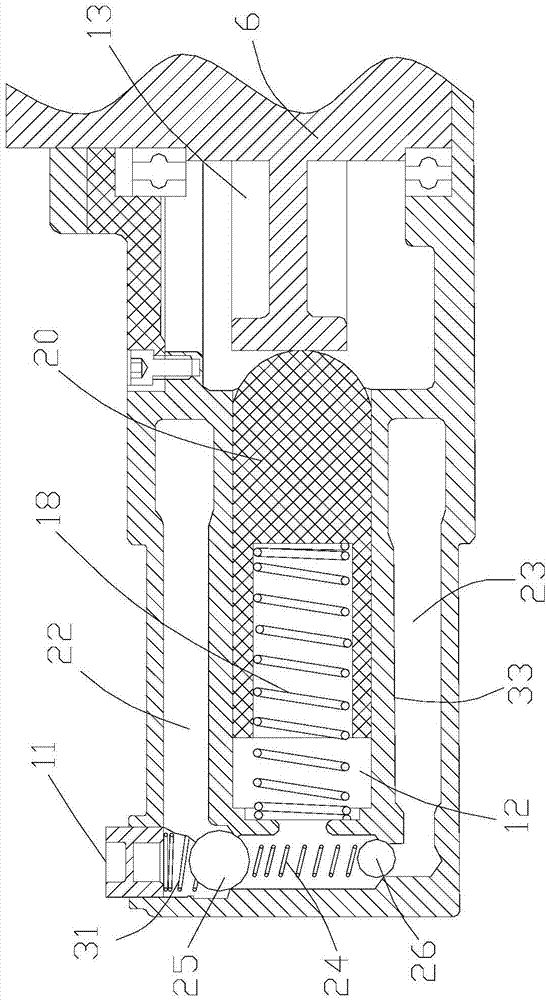

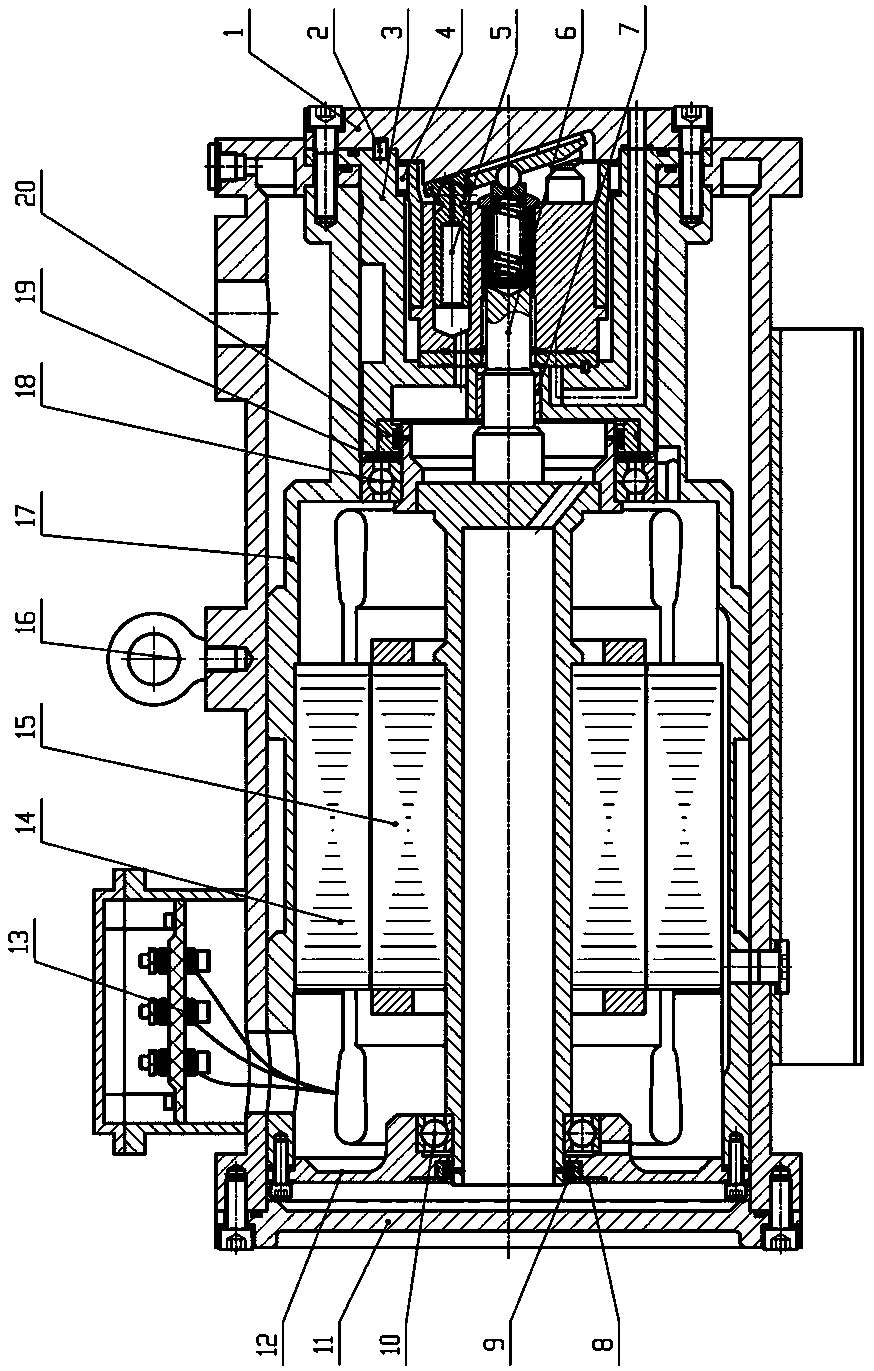

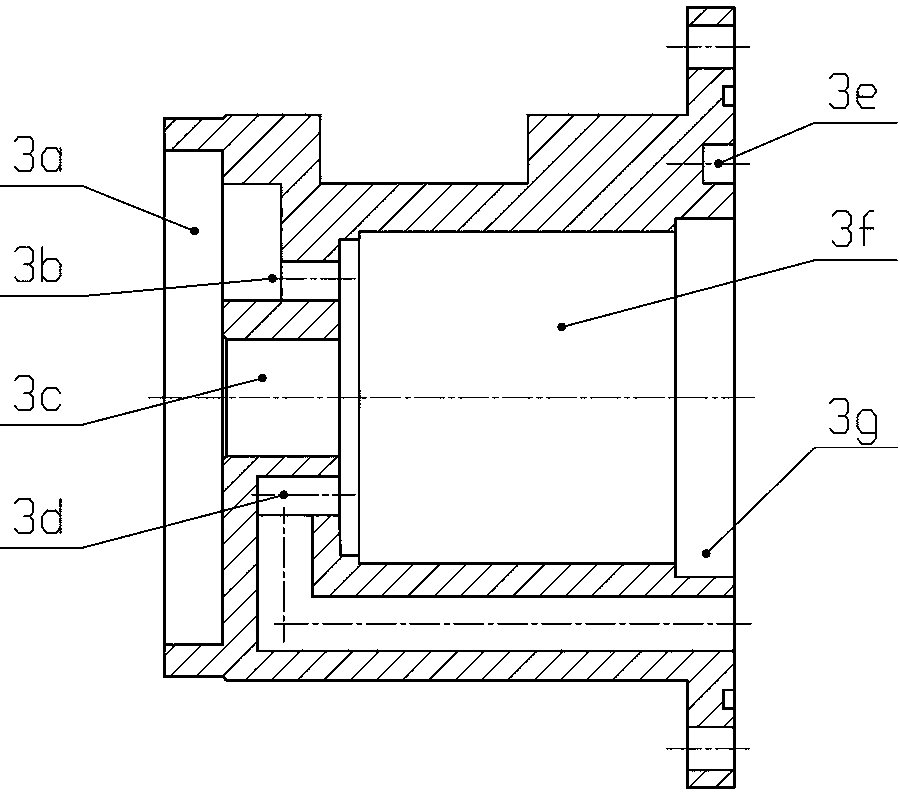

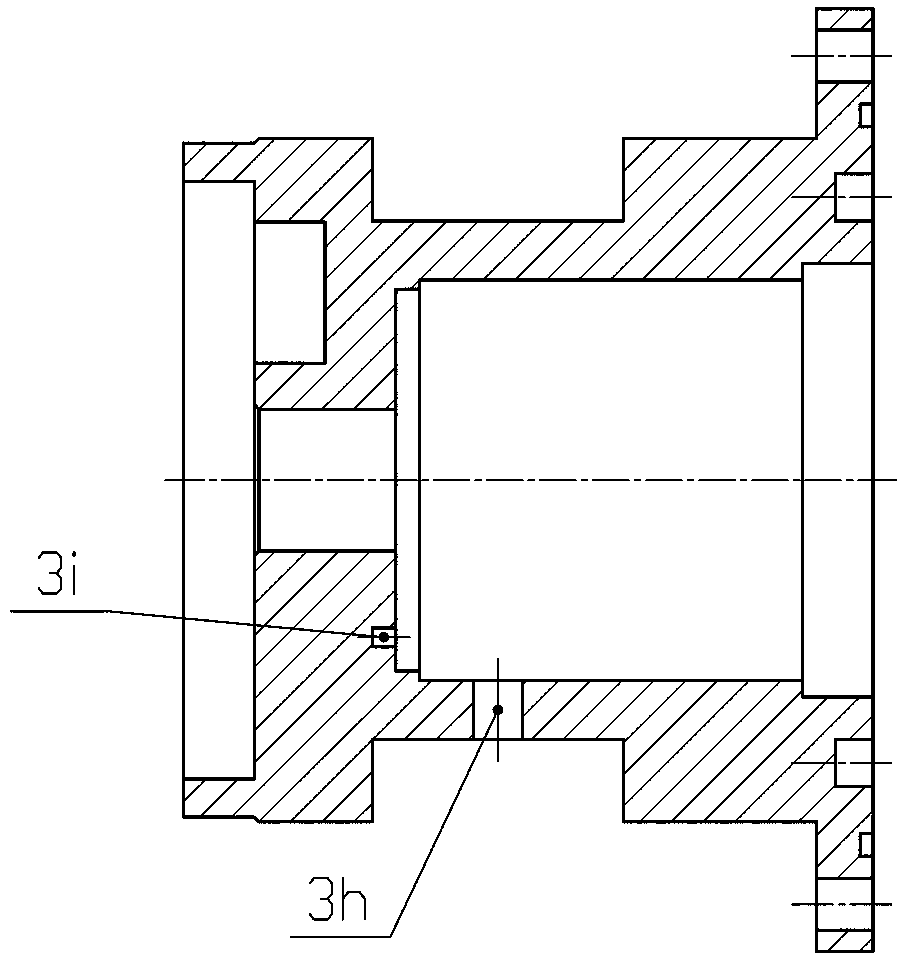

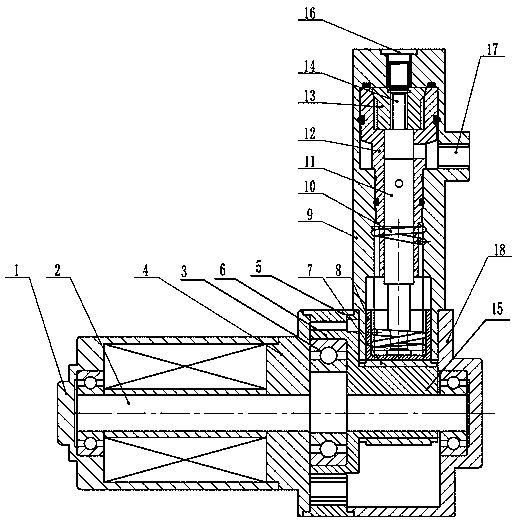

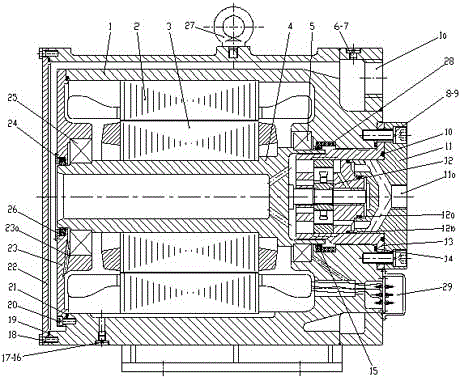

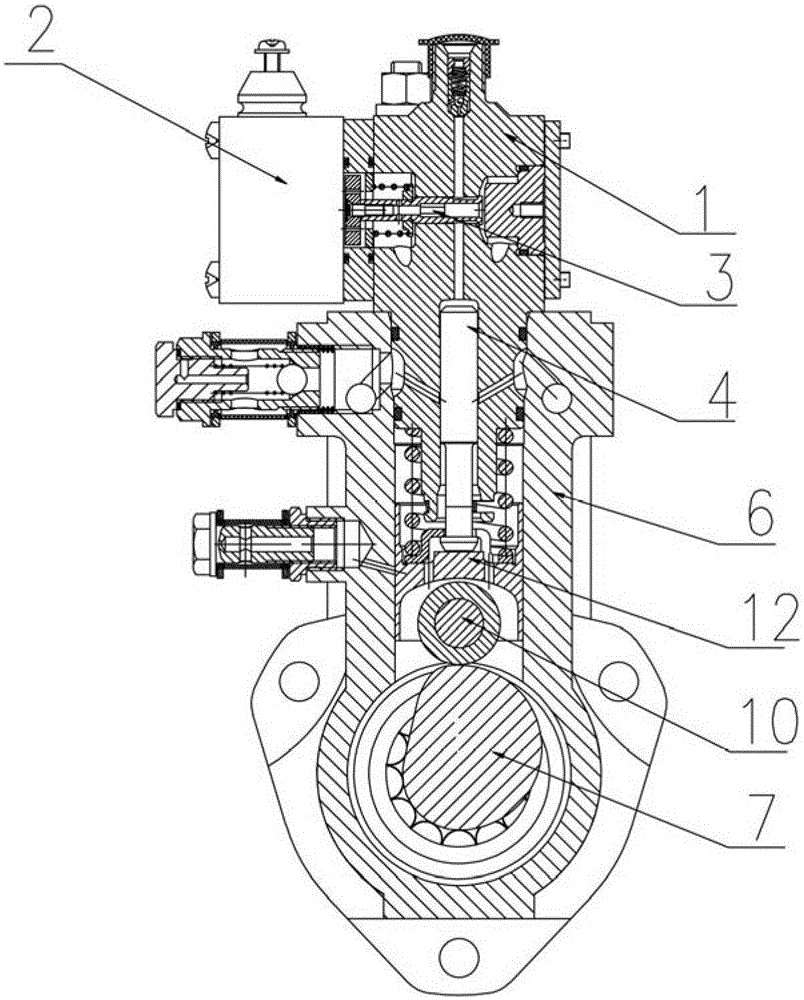

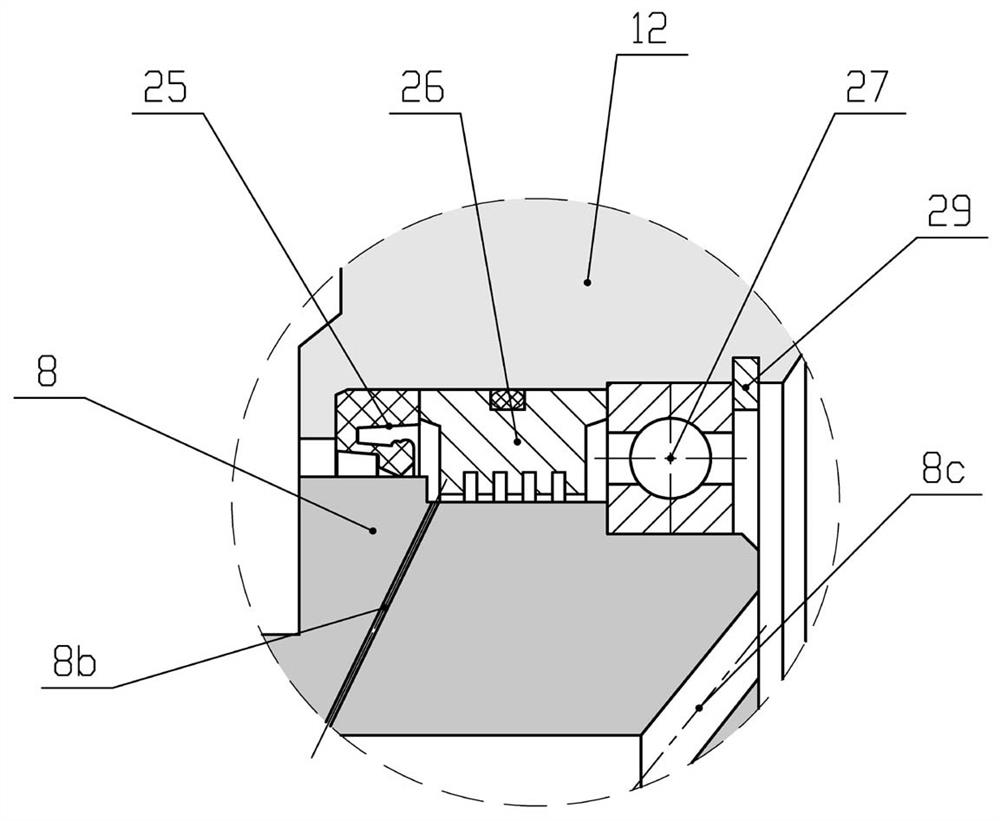

Hydraulic power unit including centrifugal pump and vane pump in motor

InactiveCN102628435ASimple structureCompact structurePump installationsPositive-displacement liquid enginesCentrifugal pumpPower unit

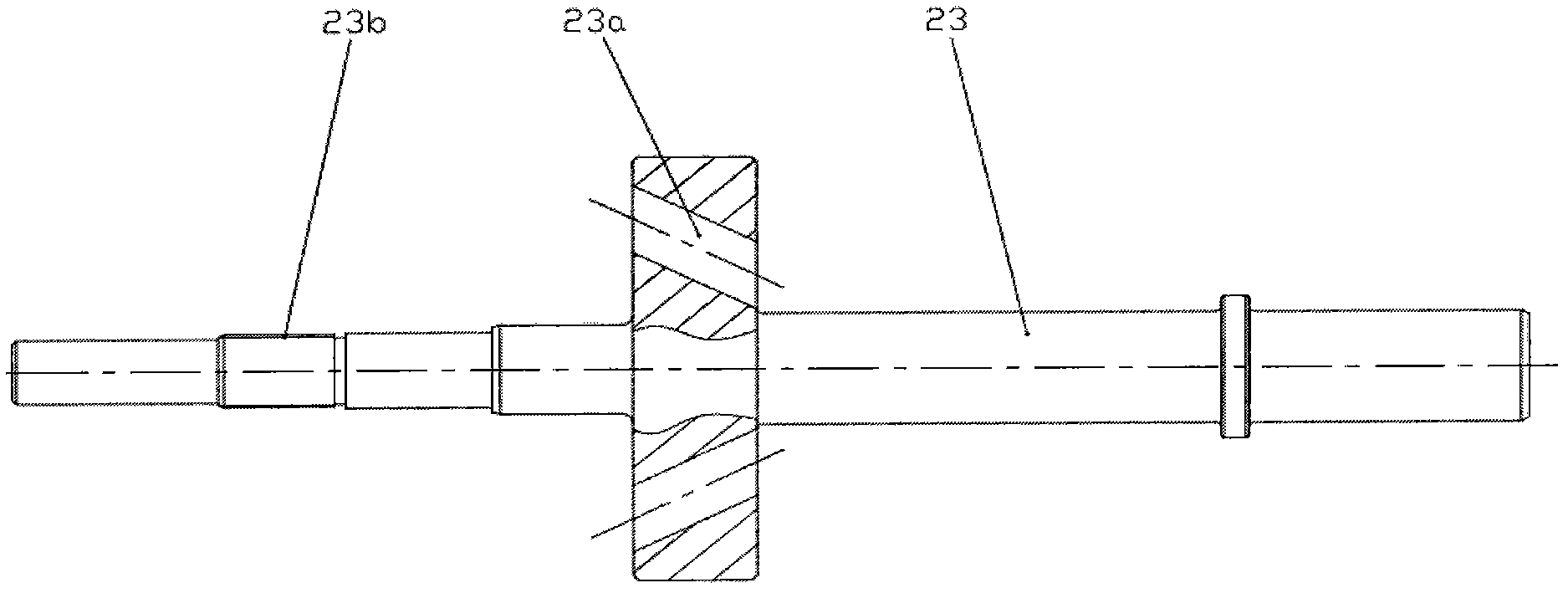

The invention provides a hydraulic power unit including a centrifugal pump and a vane pump in a motor. A motor rotor (3) is connected with a rotor sleeve (4) and a spindle (23) to form a rotor body, and is supported on an end cover (20) and a pump core seat (6) by a sliding bearing (15) in the pump core seat (6) and two groups of rolling bearings (22) in the end cover (20); the vane pump (8) is connected with a spindle (23) by a spline (23b), mounted in the pump core seat (6), and fixed on a stand (1) by an oil outlet press cover (13); a motor stator (2) is pressed on a boss (1d) within the stand (1); the end cover (20) and a sealing ring (19) are fixed on the stand (1); an oil outlet of the vane pump (8) is communicated with a runner (13a) of the oil outlet press cover (13) so as to output high pressure oil; power is supplied to the motor in the hydraulic power unit by a wiring terminal (28); and the wiring terminal (28) and a sealing ring (30) are fixed on the stand (1) by a bolt (26) and a press cover (29).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Low-speed axial plunger hydraulic pump

ActiveCN106438254AImprove work efficiencySave powerPositive displacement pump componentsPositive-displacement liquid enginesLow speedReciprocating motion

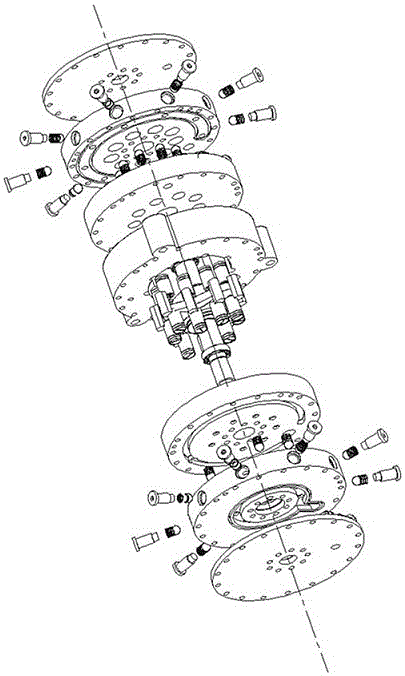

The invention provides a low-speed axial plunger hydraulic pump. A cam transmission shaft is of an overall structure formed by a transmission shaft and a cam disc. A cam case is mounted on the outer portion of the cam disc in a sleeving manner. Bidirectional joint plungers, plunger cylinder bodies, oil distribution discs and side covers are sequentially mounted on the two sides of the cam case, and the cam transmission shaft is mounted on the left oil distribution disc and the right oil distribution disc in a sleeved manner through bearings. Each bidirectional joint plunger is formed by connecting plunger bodies at the left end and the right end into a whole through a guide sliding block. The plunger bodies at the two ends of each bidirectional joint plunger and plunger cylinders of the left plunger cylinder body and the right plunger cylinder body are mounted in a clearance fit manner. The guide sliding blocks of the bidirectional joint plungers are mounted in an axial guide groove of the cam case in a sleeved manner, and the guide sliding blocks do reciprocating motion in the axial guide sleeve. The low-speed axial plunger hydraulic pump has the beneficial effects that the power input method of the cam transmission shaft is adopted, the cam transmission shaft is of the overall structure formed by the transmission shaft and the dual-face space cam disc, the dual-face space cam disc is provided with two working faces, and when the cam transmission shaft rotates by a circle, the plunger cylinders in the plunger bodies achieve two working cycles.

Owner:李海荣

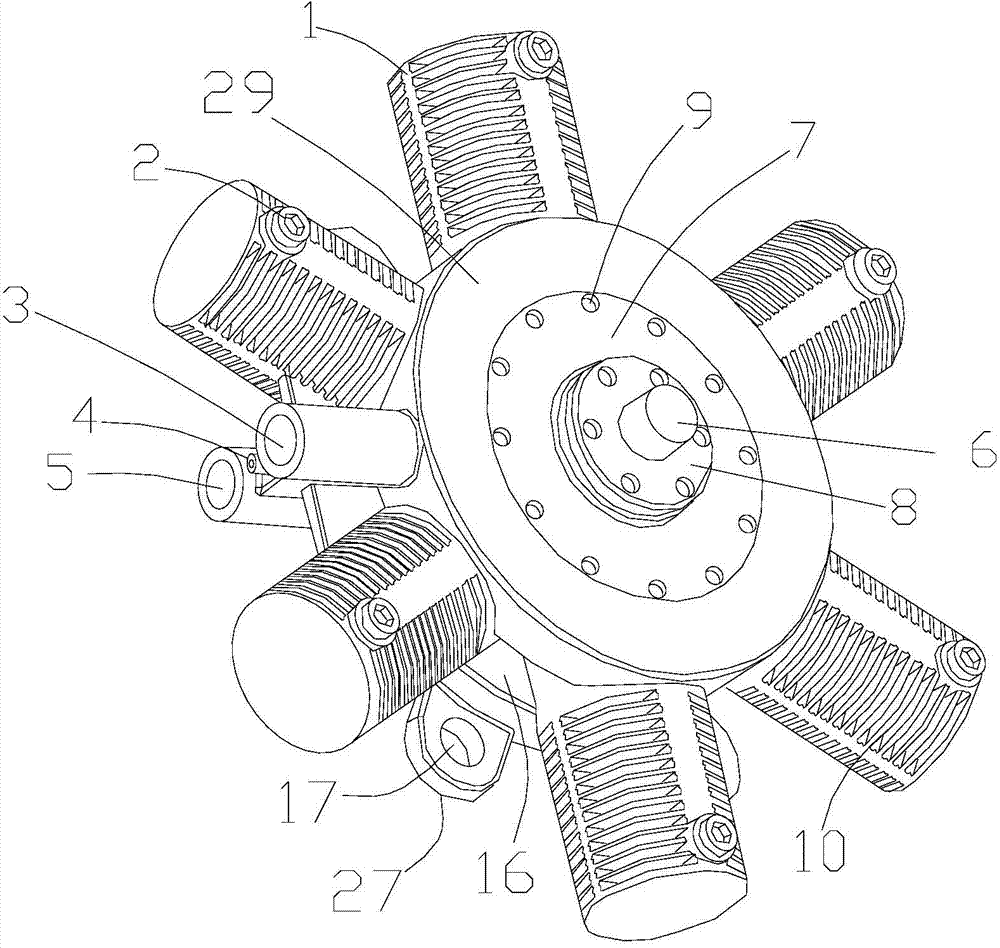

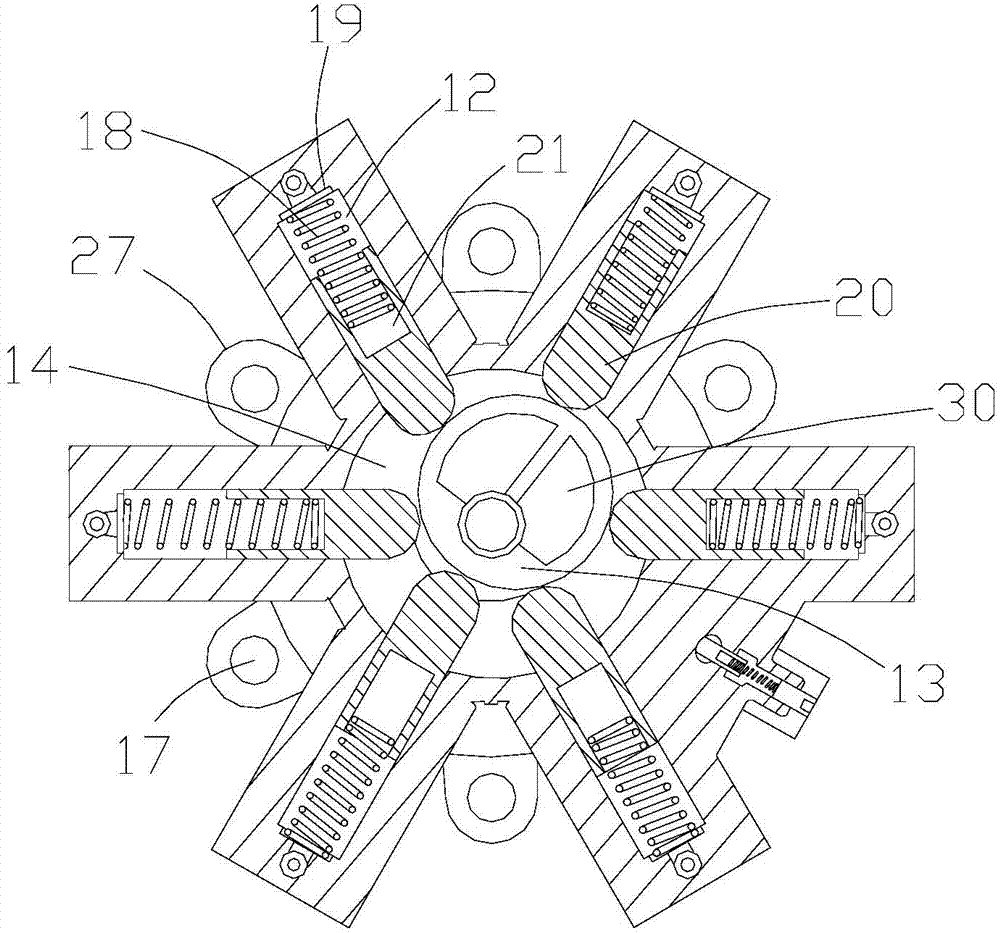

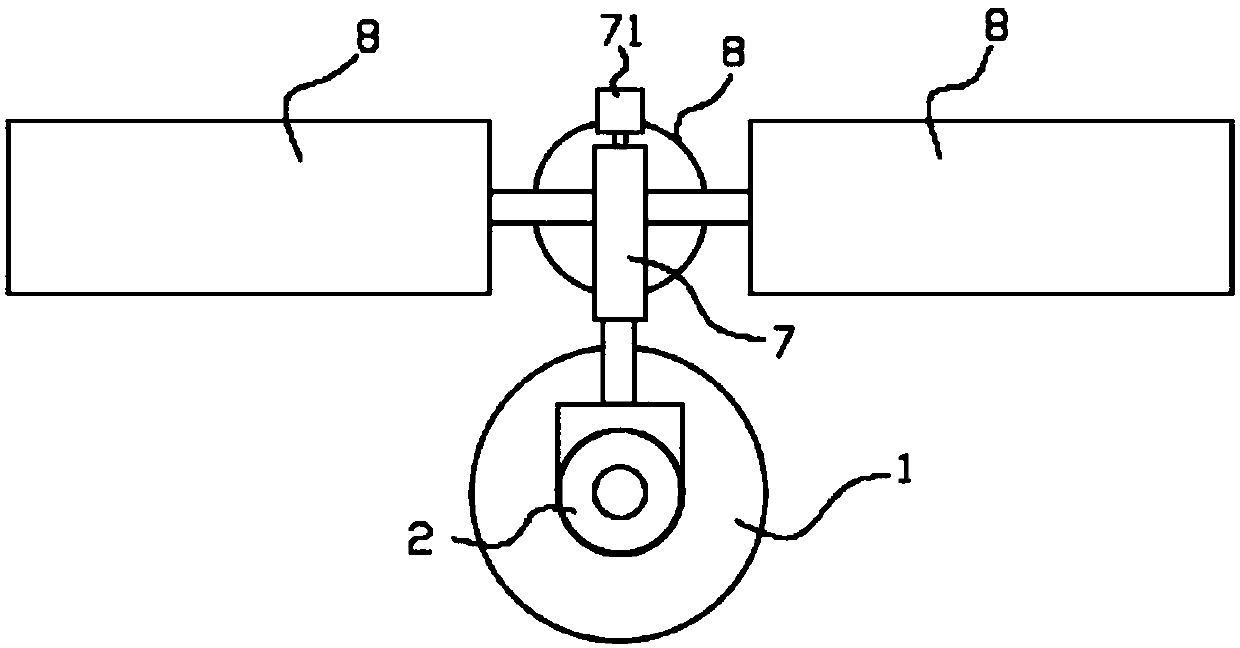

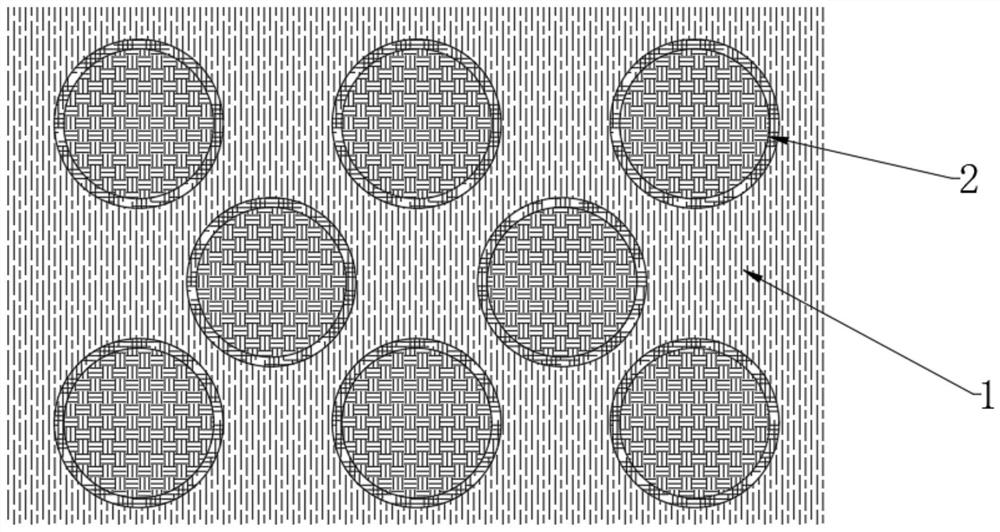

Star-shaped hydraulic pump

InactiveCN104847612AAchieve outputReduce shockPositive displacement pump componentsPositive-displacement liquid enginesHydraulic pumpEngineering

Owner:王硕 +3

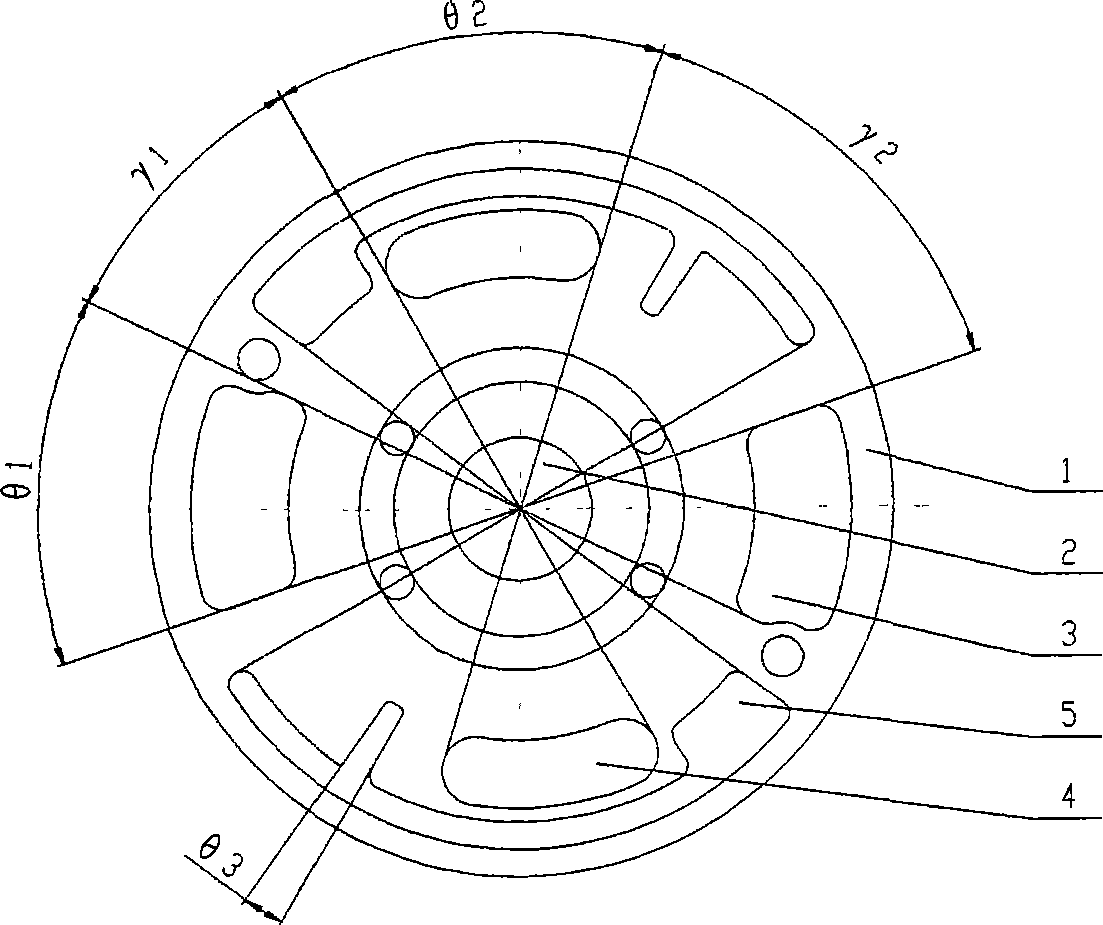

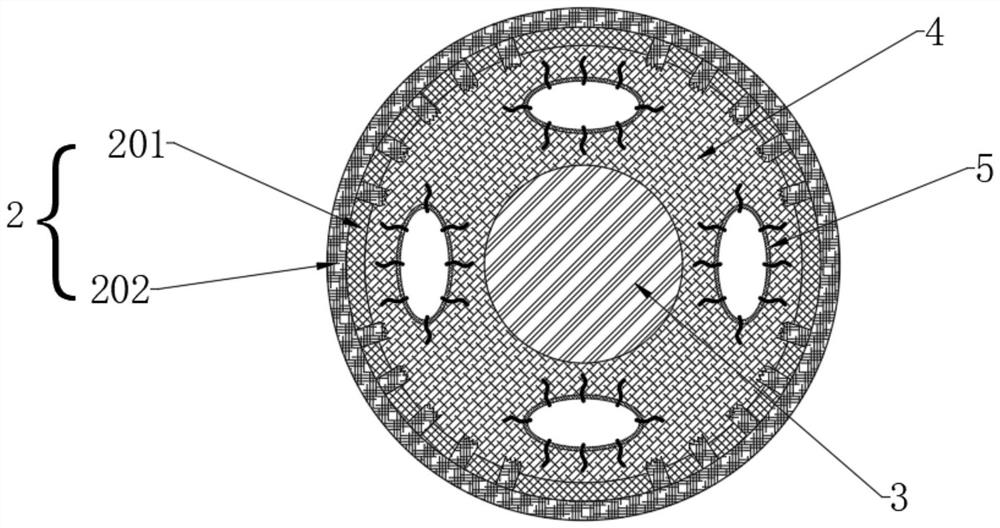

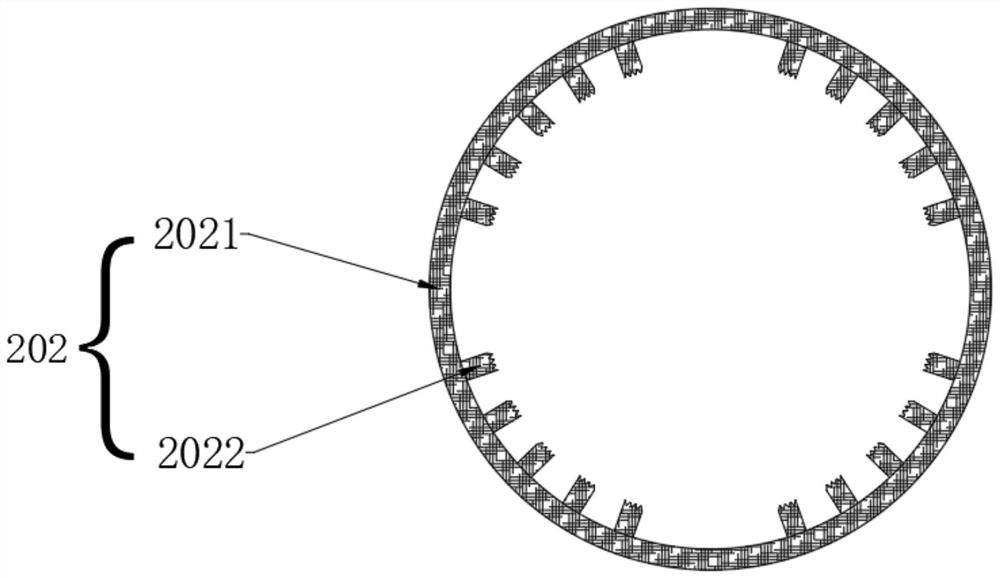

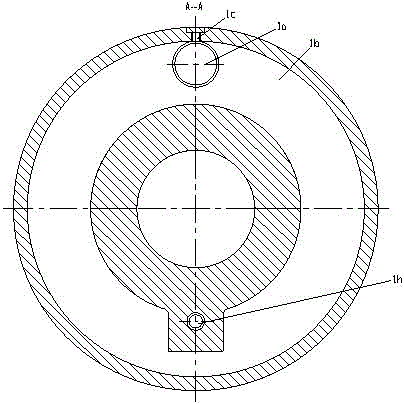

Oil distributing tray with pressure equilibrium chamber

InactiveCN101509488AFull oil absorptionReduce noiseMachines/enginesFluid steeringPressure equilibriumOil pressure

The invention discloses an oil-distributing disk with two pressure balance chambers, which mainly comprises an oil-distributing disk body and a centre hole 2. The oil-distributing disk body is provided with two oil absorption windows and two pressure oil windows which are symmetrical with the center hole, and also provided with the two pressure balance chambers which are symmetrical with the center hole. When an oil pump works, the pressure balance chambers cause that firstly the oil in the sealing volume passes the pressure balance chambers when transiting to a pressure oil chamber from an oil absorption chamber to cause the oil pressure in the chambers to rise and be close to the pressure of the pressure oil chamber, and then is communicated with the pressure oil chamber, thus reducing output oil pulsating movement. The oil-distributing disk body is provided with an oil absorption window angle theta , a pressure oil window angle theta and a pressure balancing chamber angle theta which are symmetrical with the centre hole and respectively account for 12-25%, 12-25%, and 0.5-1% of the periphery of the oil-distributing disk. The angel gamma and gamma of the sealing areas between the two oil absorption windows and the two pressure oil windows respectively account for 18-25% and 20-30% of the periphery of the oil-distributing disk. The oil-distributing disk is applied to a motor steering pump.

Owner:傅松权

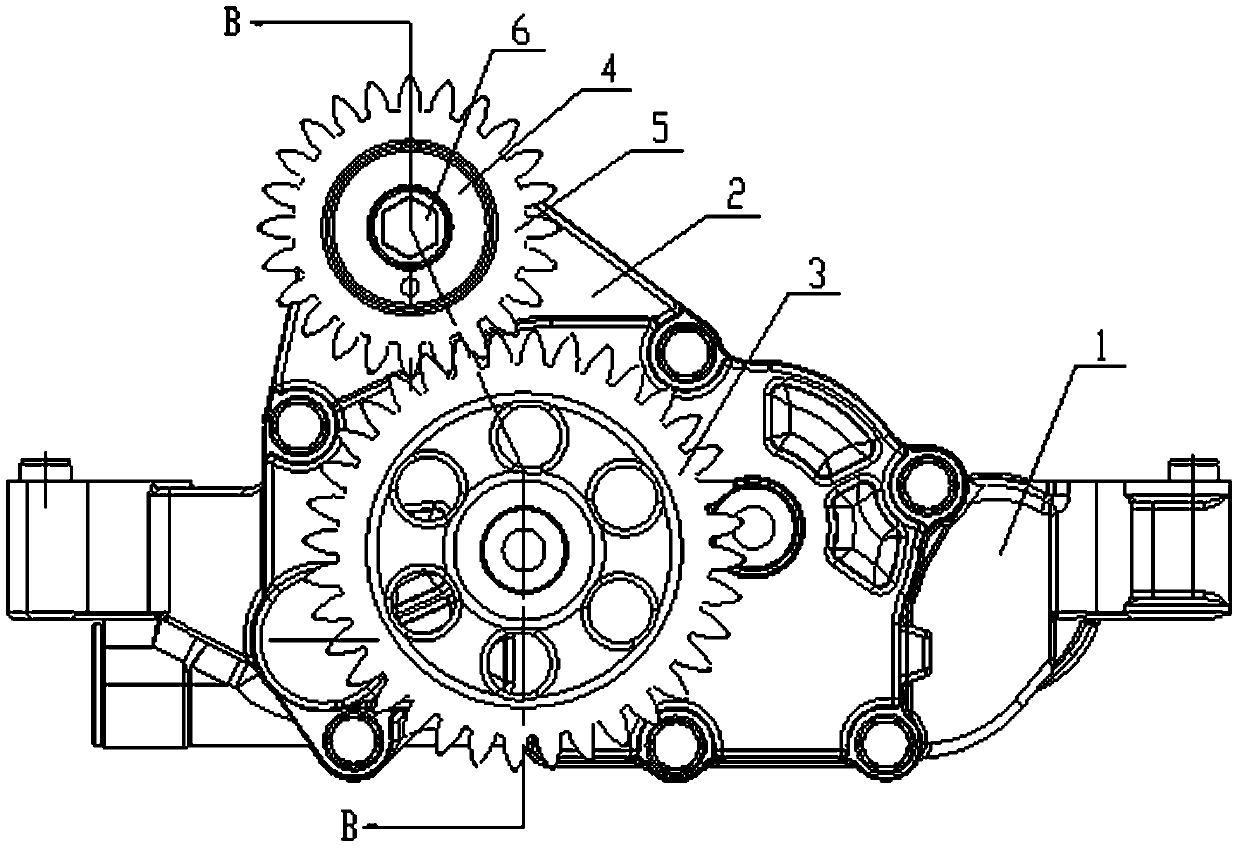

Structure-optimized machine oil pump with idle gear

PendingCN109827061AReduce weightAchieve oil circulationEqualizing valvesRotary piston pumpsEngineeringHigh pressure

The invention provides a structure-optimized machine oil pump with an idle gear. The machine oil pump comprises a pump body, a pump cover, an idle gear shaft, the idle gear and a bolt; an oil cavity is formed in the pump body; an idle gear shaft mounting hole is formed in the pump cover; the idle gear shaft is provided with an axial bolt mounting hole and a lubricating through hole intersected with the bolt mounting hole; the idle gear sleeves the idle gear shaft; a screw plug fixes the idle gear shaft on the pump cover; the diameter of the bolt is smaller than the aperture of the bolt mounting hole of the idle gear shaft; an annular gap is formed between the bolt and the inner wall of the bolt mounting hole; an oil passing groove is formed in the side, near an oil cavity, of the round hole bottom surface of the idle gear shaft mounting hole; an inclined oil hole communicating with the oil cavity is drilled in the pump cover through the oil passing groove; high-pressure oil in the oilcavity flows into a gap between an idle gear bushing and the idle gear shaft through the inclined oil hole, the oil passing groove, the annular gap and the lubricating through hole in sequence; and oil leakage grooves are formed in two end surfaces of a shaft table of the idle gear.

Owner:HUNAN OIL PUMP

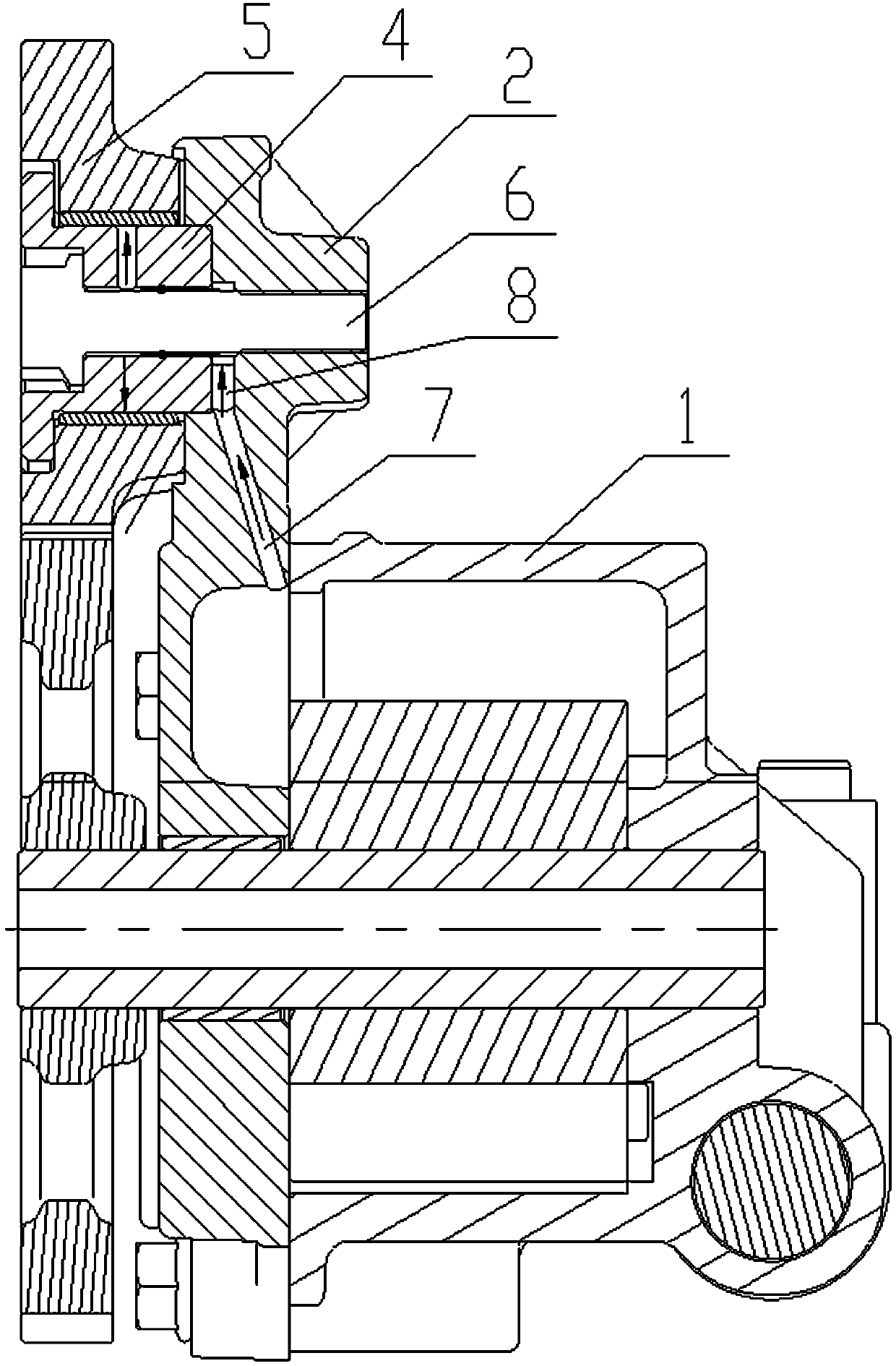

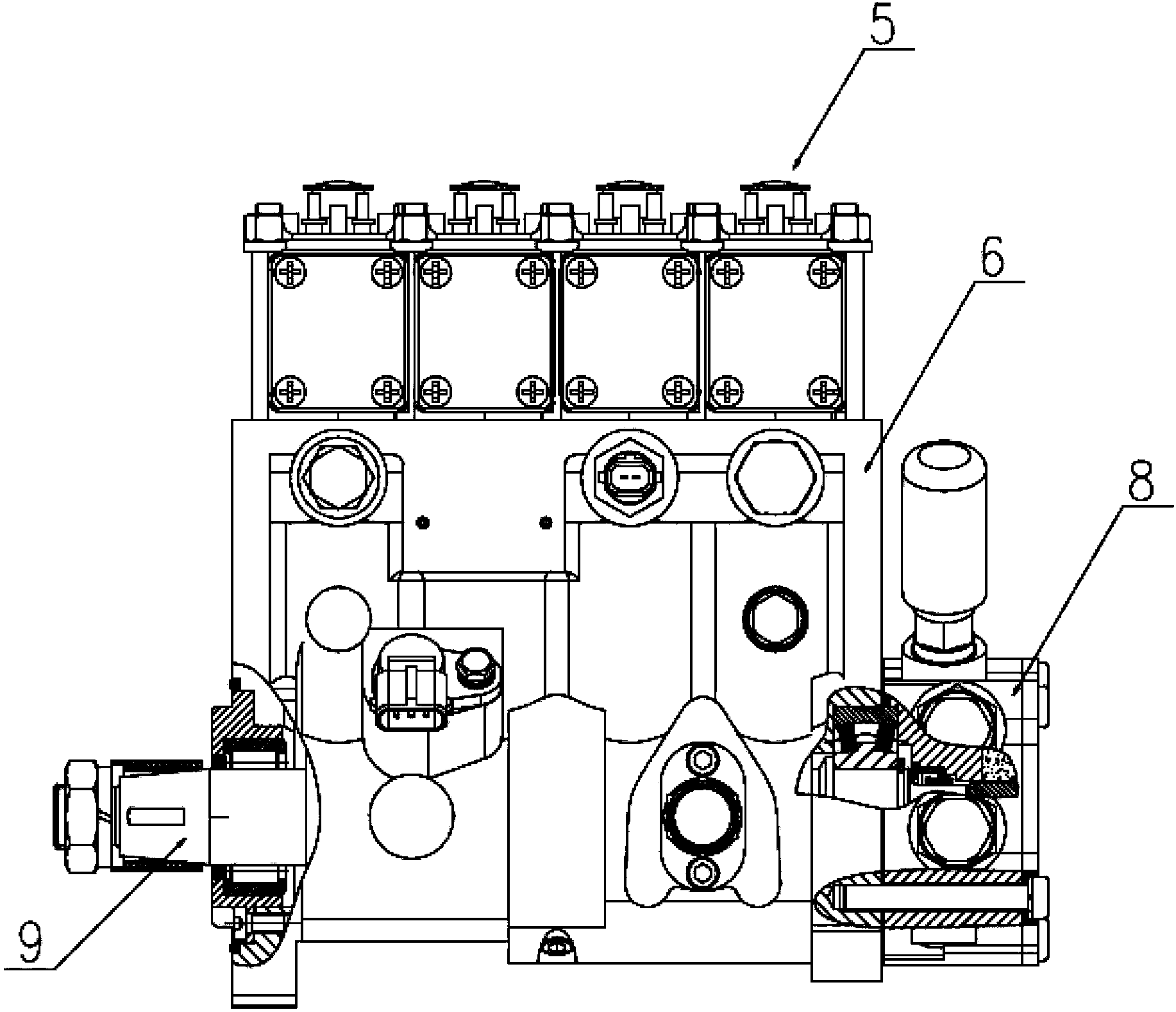

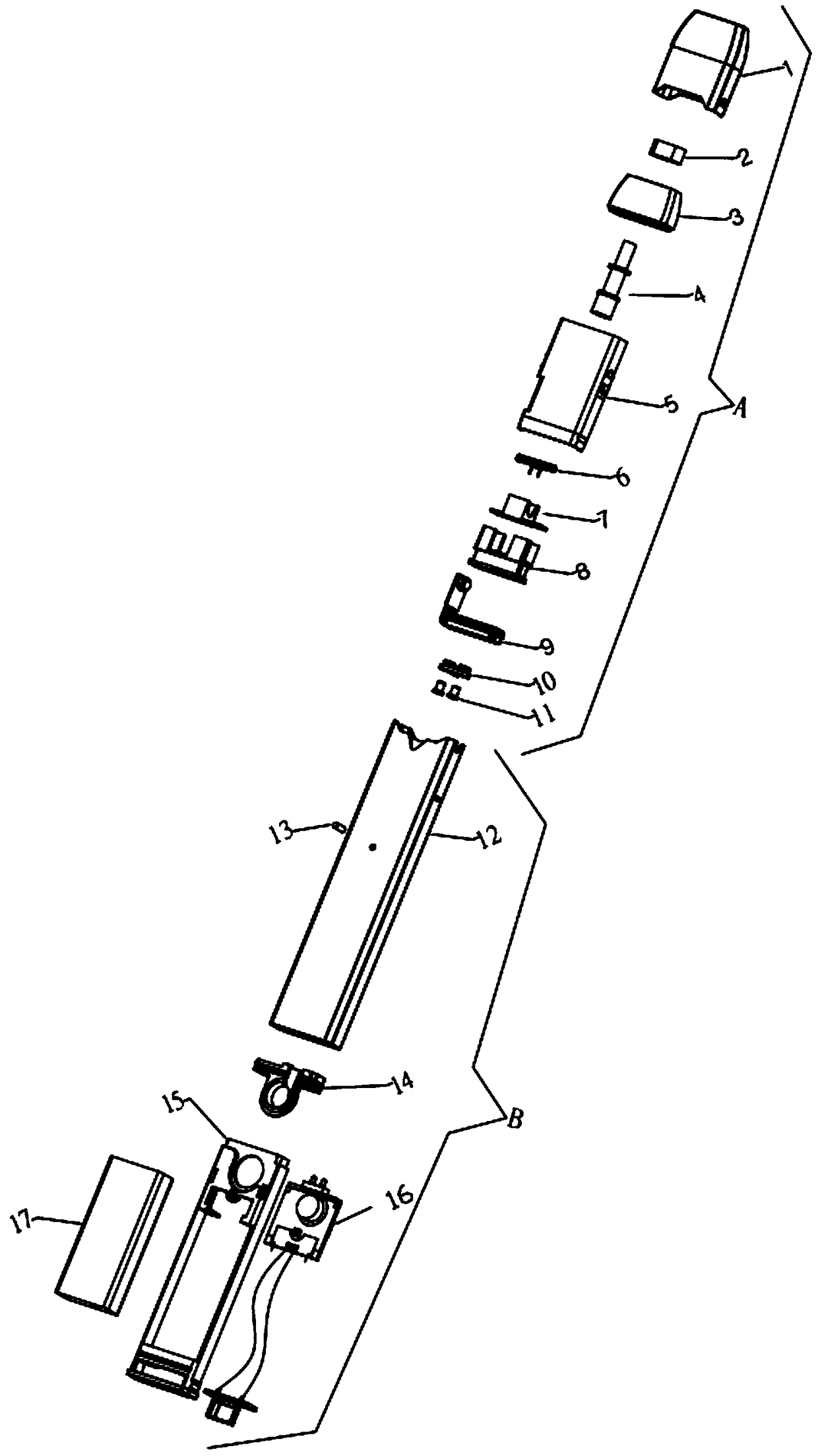

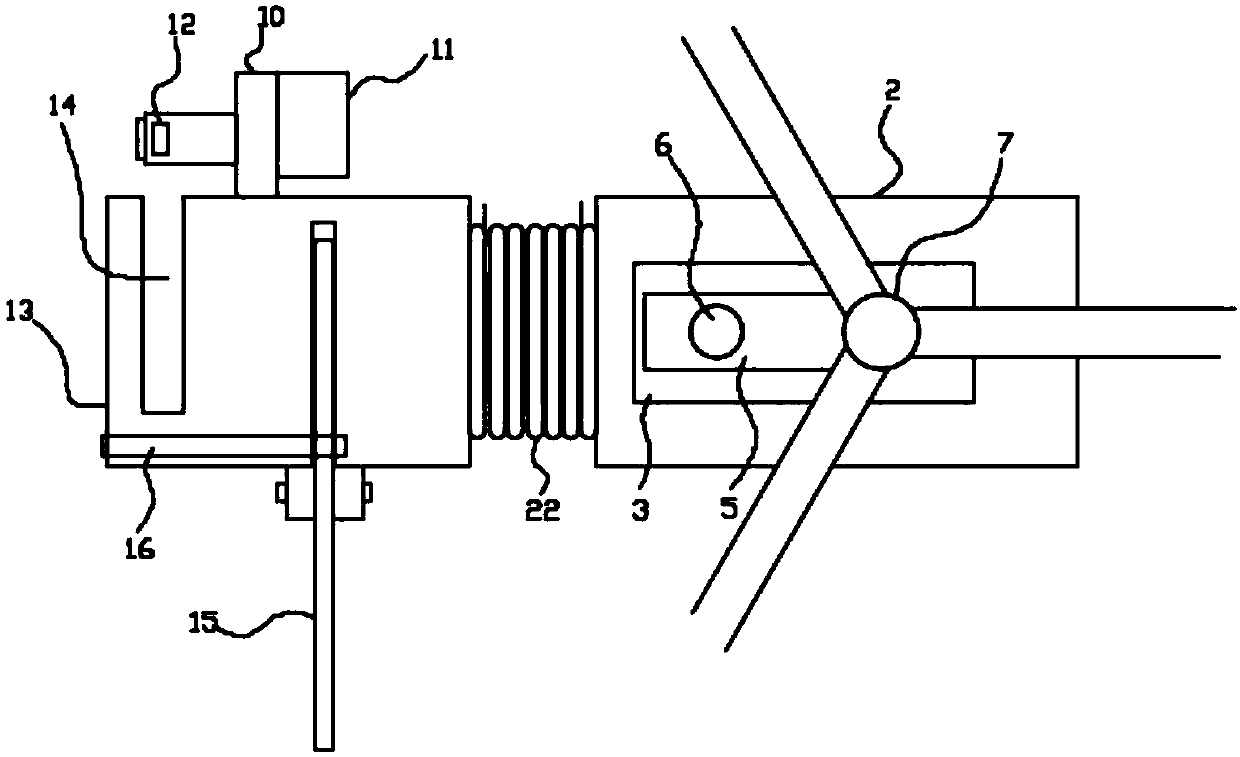

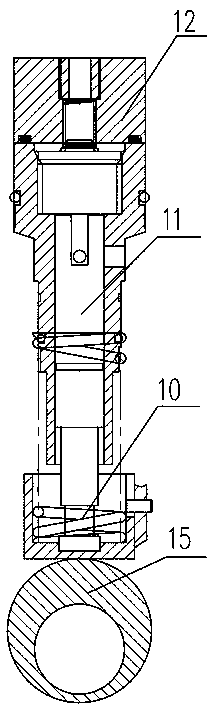

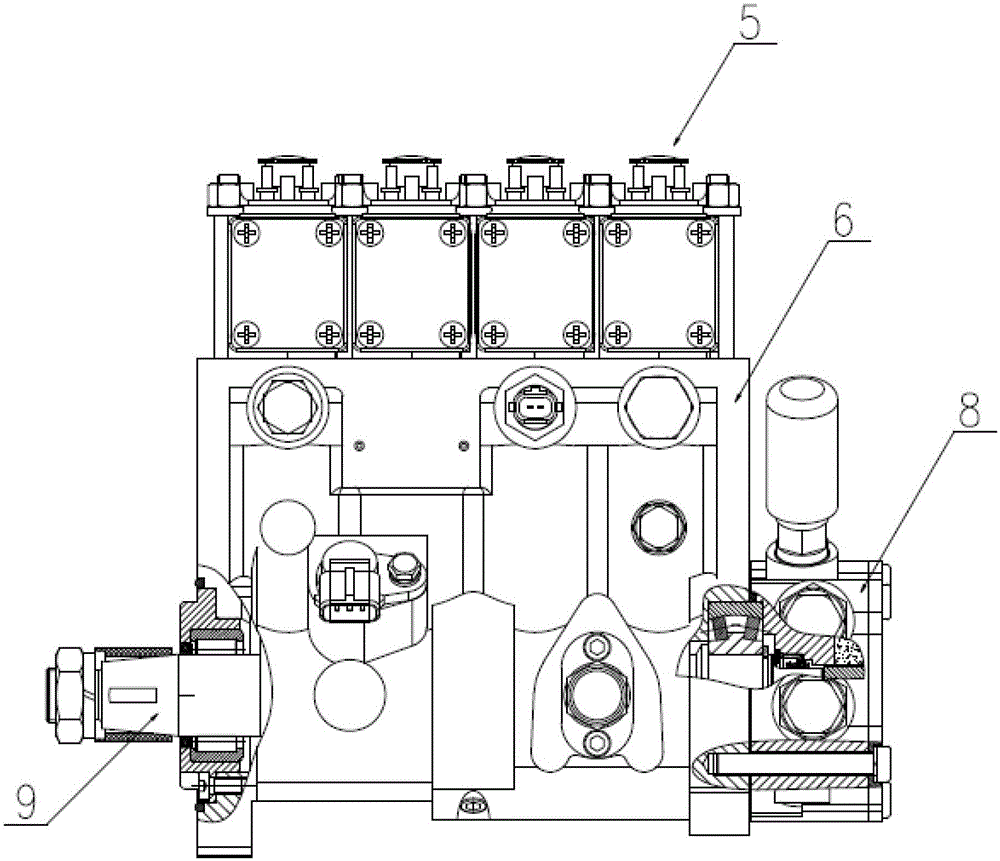

Electronic unit composite pump for light-vehicle diesels

ActiveCN103410643AGuaranteed working lengthReduce weightFuel injection apparatusMachines/enginesCamEngineering

The invention relates to the technical field of vehicle engine manufacturing, in particular to an electronic unit composite pump for light-vehicle diesels. The electronic unit composite pump for light-vehicle diesels comprises a composite pump body, an oil conveying pump, a camshaft, a plurality of electronic unit pumps, tappet body assemblies corresponding to the electronic unit pumps and a cam, and is characterized in that the electronic unit pumps are installed on the composite pump body and comprise unit pump bodies, a plunger, control valve elements and electromagnets installed on one sides of the unit pump bodies, the oil conveying pump is installed on one side of the composite pump body, the tappet body assemblies are arranged between the cam and the plunger and comprise tappets, rolling wheels and rolling wheel pins, and U-shaped cavities are formed in the ends where the tappets make contact with the rolling wheels, wherein the plunger and the control valve elements are arranged in the unit pump bodies. The electronic unit composite pump for light-vehicle diesels has the advantages of being more compact in structure and capable of acquiring higher working speed so as to be matched with the high-speed diesels.

Owner:龙口龙泵柴油喷射高科有限公司

Diesel engine single pump with high oil suction capacity

PendingCN107401466AAvoid running stability flawsDefects affecting operational stabilityMachines/enginesFuel injecting pumpsDieselingFuel oil

The invention discloses a diesel engine single pump with a high oil suction capacity, and aims to provide a single pump capable of improving the flow area of an oil suction channel and the oil suction capacity. The invention is realized through the following technical scheme that a lower valve seat is located below a conical surface of the shaft end of a valve rod; a high-pressure oil channel communicating with a conical valve hole and a low-pressure oil channel communicating with a central channel are formed in the lower valve seat; when a plunger goes downward, the volume of a plunger cavity is increased, the pressure of fuel oil in the plunger cavity is reduced, a sealing ball is separated from the conical valve hole, and a large-area circulating oil inlet channel is formed; the fuel oil flows into the plunger cavity from an oil inlet connector through the low-pressure oil channel, the conical valve hole and a central hole of a limiting ball seat; when the plunger goes upward, the volume of the plunger cavity is decreased, the pressure of the fuel oil is increased, the conical valve hole is closed by the sealing ball, and the fuel oil is prevented from flowing to the low-pressure oil channel (17) from the conical valve hole; and the fuel oil in the plunger cavity is forced only to flow to the oil inlet connector from the high-pressure oil channel through a valve rod neck oil path channel formed at a valve rod neck section and the low-pressure oil channel. Therefore, the problem that the flow area of the oil suction channel is small is solved.

Owner:成都威特电喷有限责任公司

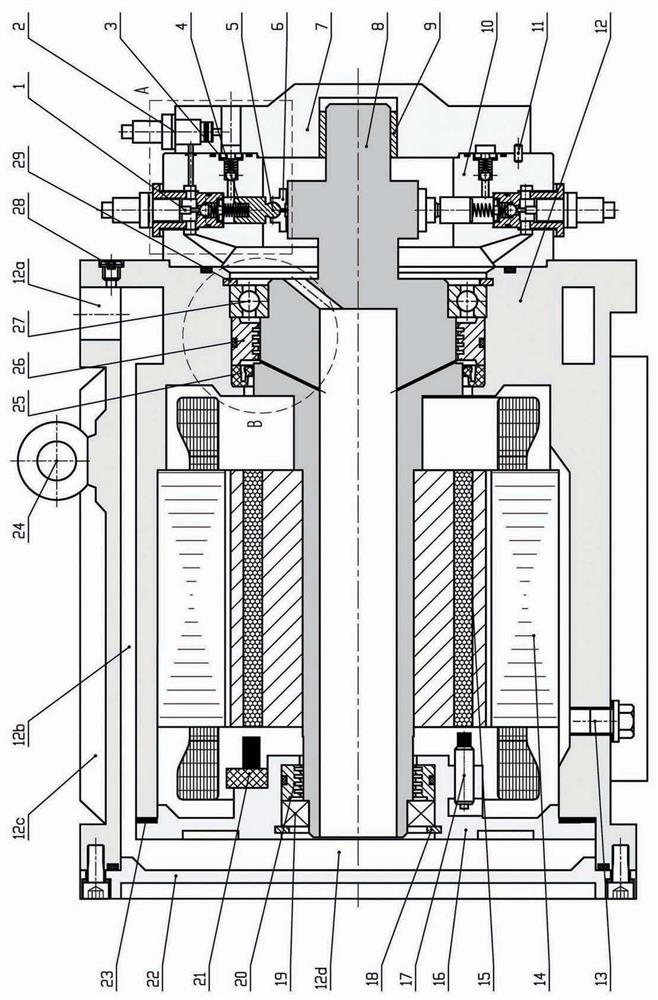

Air gap non-oil-immersion type axial plunger motor pump

InactiveCN110500257AHigh oil absorptionFull oil absorptionPositive displacement pump componentsPump installationsTransmitted powerFriction loss

The invention discloses an air gap non-oil-immersion type axial plunger motor pump. The air gap non-oil-immersion type axial plunger motor pump is an integrated integration of a motor, an axial plunger pump and an orifice type centrifugal pump. The composite shaft (6) integrates the central shaft of the motor, a main shaft of the plunger pump and the orifice centrifugal pump, the composite shaft not only has the function of transmitting power, but also has the functions of fluid circulation, strengthening convection heat dissipation and auxiliary pressurization, the composite shaft is hot assembly with motor rotors (15), the composite shaft is supported in a shell body (17) and the inner end cover (12) through first bearings (18) and second bearings (10), both ends are sealed by first sealparts (20) and second seal parts (9) to prevent hydraulic oil from entering air gaps between the motor stators (14) and the rotors (15). According to the air gap non-oil-immersion type axial plungermotor pump, the non-contact type labyrinth sealing structure is adopted, extra friction loss caused by contact between the sealing ring and the shaft is avoided, the efficiency of the motor pump is further improved, a pump core (5) of the plunger pump is connected with the composite shaft (6) through a spline, and the pump core is supported in the pump core seat (3) through a third bearing (4).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

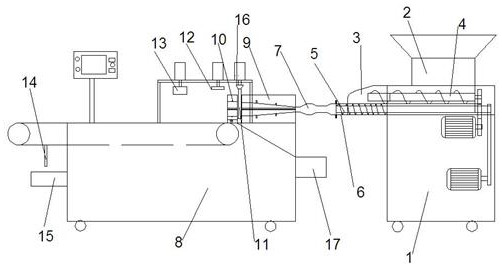

Core-casting gluten processing device capable of fast adjusting cores and process for processing gluten

PendingCN108056374AGreat tasteImprove chewinessFood preservationDough shaping and cutting apparatusImpellerEngineering

The invention discloses a core-casting gluten processing device capable of fast adjusting cores. An extrusion pipe is arranged at the end of a first screw extruder; a core pipe is arranged in the extrusion pipe, and the tail end of the core pipe is connected to a lifting pipe to form an L shape; the upper end of the lifting pipe is connected to a delivery cylinder; a second screw extruder is connected to the side wall of the delivery cylinder; a flavoring device is arranged inside the delivery cylinder; the flavoring device is connected to a flavoring motor; the upper end of the extrusion pipeis provided with a lifting mechanism for controlling the lifting pipe to move up and down; a rotating shaft is arranged in the core pipe; the tail end of the rotating shaft extends out and is provided with an impeller; the front end of the rotating shaft is provided with a guide plate; a material delivery hole deviating from the center is arranged on the guide plate; the guide plate blocks the outlet of the core pipe; and the inner wall of the upper end of the extrusion pipe is provided with a hiding groove for hiding the core pipe and the impeller. The device can realize the processing of the screw-type core-casting gluten, realize the continuous diversified adjustment of the taste of cast core of the gluten, and greatly improve the taste diversification of the gluten.

Owner:HUNAN YUFENG FOOD IND

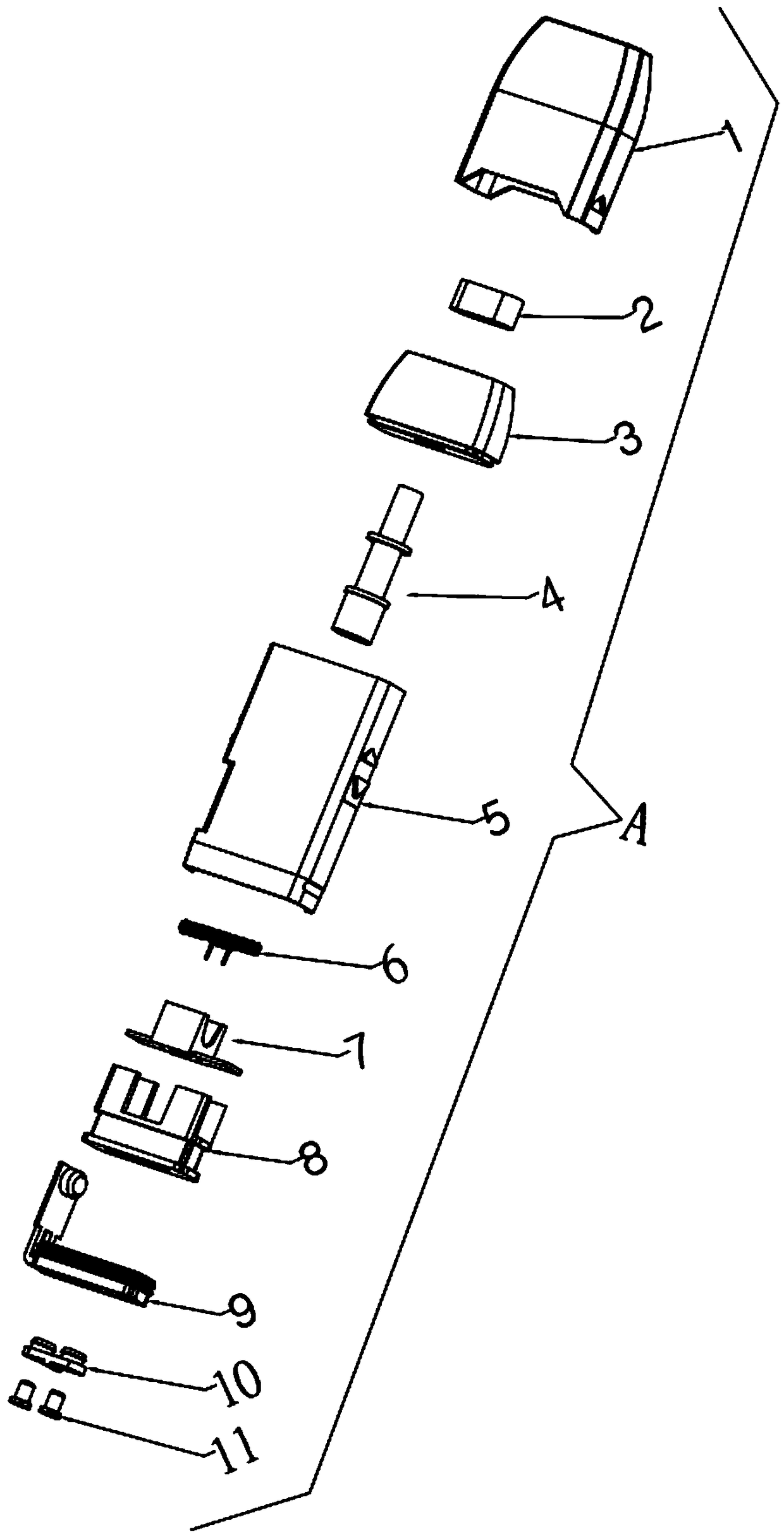

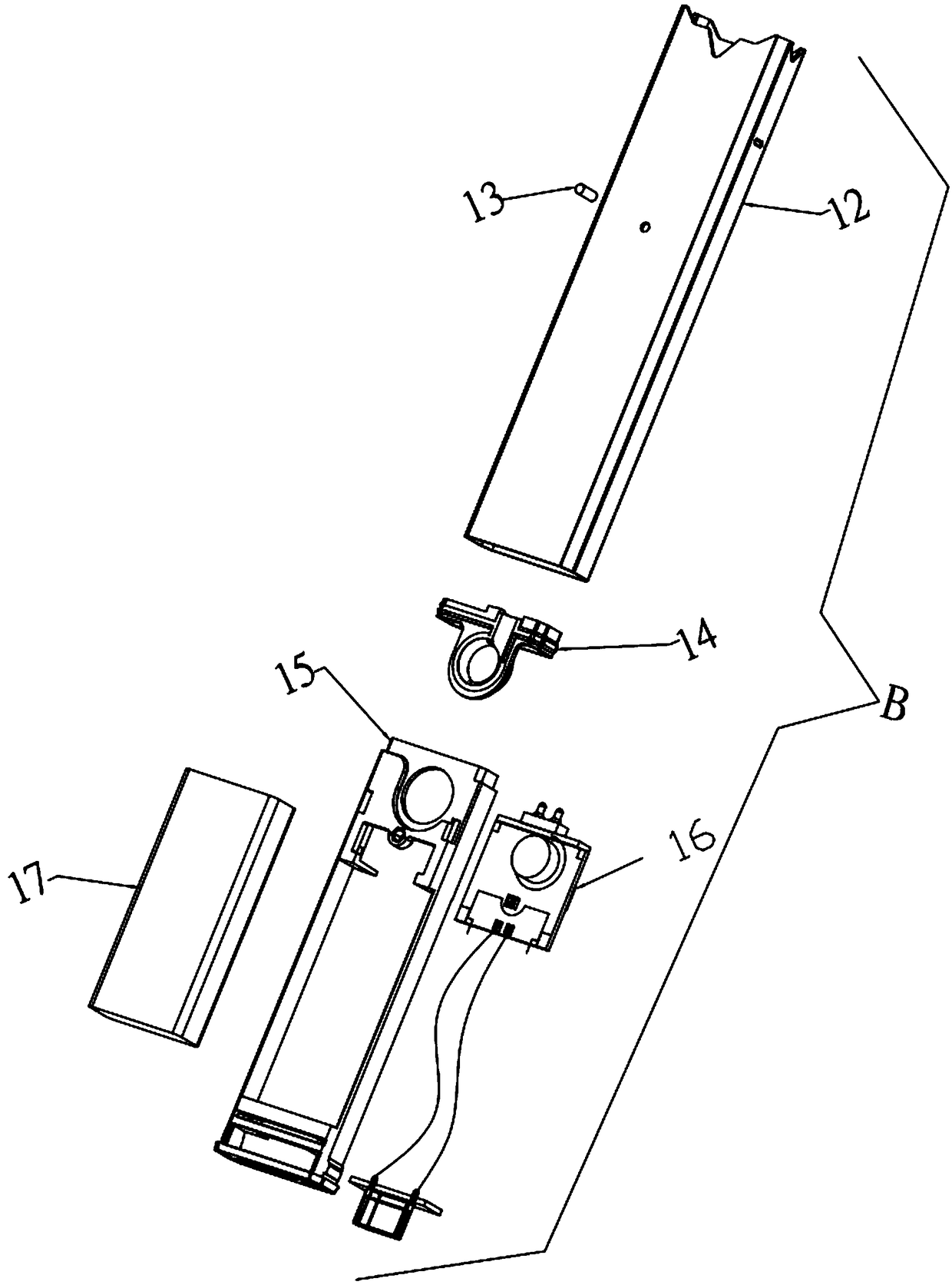

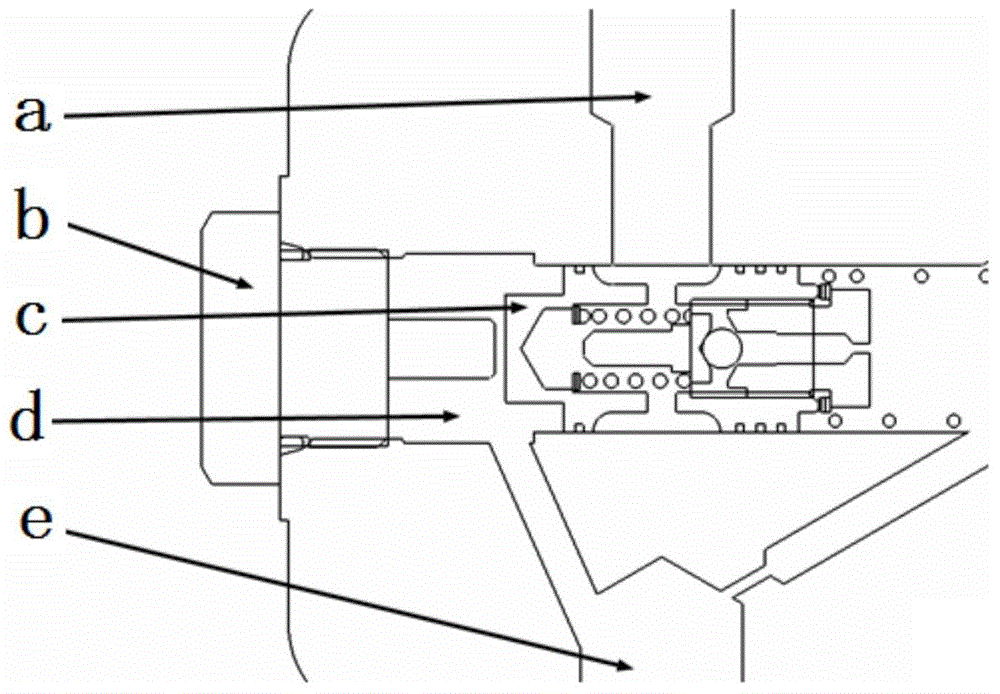

A flat disposable cigarette bomb

InactiveCN109156901AExtend the life cycleFlat surfaceTobacco devicesEngineeringMechanical engineering

The invention discloses a flat disposable cigarette bomb comprising a flat atomizer assembly (A) and a battery assembly (B), wherein the atomizer assembly is positioned above the battery assembly; wherein the atomizer of the atomizer assembly (A) is mounted in a battery rod (12) of the battery assembly and is connected together by a bump on an oil cup (5) body of the atomizer assembly and a recessin the battery rod (12). The flat disposable cigarette bomb has the advantages of flat shape, high durability and long service life.

Owner:刘团芳

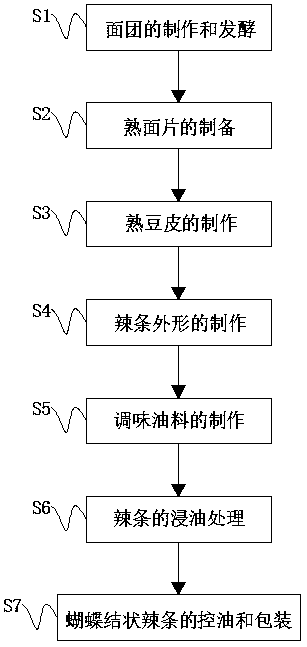

Making method of vegetarian special-shaped spicy gluten

The invention discloses a making method of vegetarian special-shaped spicy gluten, and relates to the technical field of food processing. The method particularly comprises the following steps of S1, dough making and fermentation; S2, making of cooked dough sheets; S3, making of cooked beancurd skins; S4, making of spicy gluten shapes; S5, making of seasoning oil; S6, oil immersion treatment for spicy gluten; S7, oil control over the bowknot-shaped spicy gluten and packaging of the bowknot-shaped spicy gluten. According to the making method of the vegetarian special-shaped spicy gluten, the spicy gluten shape can be improved, through the twining design of the cooked dough sheets and the cooked beancurd skins, the two ends of each cooked dough sheet still spread, the effect of oil immersionfor the spicy gluten is ensured, the requirements of an eater for the taste of the spicy gluten is met well, and the requirement of the eater for the ornamental value of the spicy gluten is also met;various kinds of seasoning are mixed with an oil material, the fermentation oil absorption performance of flour is added, then oil immersion treatment is conducted, and the purposes that the taste andflavor of the spicy gluten are ensured, and meanwhile, the content of a flavouring agent in the flour used for making the spicy gluten is reduced are achieved.

Owner:平江县新翔宇食品有限公司

Filled gluten food production device and gluten processing technology

PendingCN108041424AGreat tasteImprove chewinessFood preservationDough shaping and cutting apparatusImpellerGluten

The invention discloses a filled gluten food production device and a gluten processing technology. An extrusion pipe is arranged at one end of a first screw extruder, and a core pipe is arranged in the extrusion pipe; the core pipe is connected with a lifting pipe; multiple second screw extruders are connected onto the side wall of a material conveying cylinder; a material blending device is arranged at the upper end of the material conveying cylinder; a lifting mechanism is arranged at the upper end of a blended material extrusion pipe; a rotating shaft is arranged in the core pipe; a spiralblade is arranged on the rotating shaft; an impeller is arranged at the tail end of the rotating shaft and a material guide plate is arranged at the front end of the rotating shaft; a material conveying hole is formed in the material guide plate; a mounting head is connected with the front end of the core pipe in a threaded manner, and a spline hole seat connected with the rotating shaft is arranged in the center of the material guide plate; a hidden groove is formed in the inner wall of the upper end of the extrusion pipe; an adjusting plate is arranged at the front end of the extrusion pipe,and the side edge of the adjusting plate is inserted into the extrusion pipe; and gluten cutting holes are formed in the adjusting plate. Spiral core-filled gluten can be processed, the gluten is filled with different food materials, the size and the shape of the gluten can be adjusted, the type and length of filling cores can be adjusted, and the diversity of the taste of the gluten is greatly improved.

Owner:HUNAN YUFENG FOOD IND

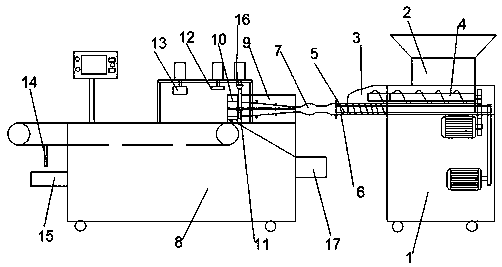

Automatic forming machine for walnut cakes and mung bean cakes

ActiveCN110771646AFull oil absorptionExtended shelf lifeDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusMolding machineAgricultural engineering

The invention discloses an automatic forming machine for walnut cakes and mung bean cakes. The forming machine comprises a feeding mechanism and a forming mechanism, and the feeding mechanism comprises a feeding rack. A hopper is arranged on the feeding rack; a flour compression cavity is formed in the lower end of the hopper; a feeding compression reel and a feeding reel are arranged on the two sides in the flour compression cavity; a connecting pipe is welded at the front end of the flour compression cavity; the front end of the connecting pipe is connected to a feeding nozzle; the feeding nozzle is connected to the forming mechanism; the forming mechanism comprises a forming rack, wherein a blank transition channel is arranged on the forming rack, a blank forming part is arranged at thefront end of the blank transition channel, a transverse cutting baffle is arranged on the forming rack, a bracket is arranged on the forming rack, a first forming cylinder and a second forming cylinder are arranged on the bracket, and a forming pressing plate and a forming die are respectively arranged at the lower ends of the first forming cylinder and the second forming cylinder. The forming machine is simple in structure and reasonable in design, walnut cakes and mung bean cakes can be produced at the same time, meanwhile, the crispness of the walnut cakes can be improved, and the producedmung bean cakes are not prone to breakage.

Owner:谭爱平

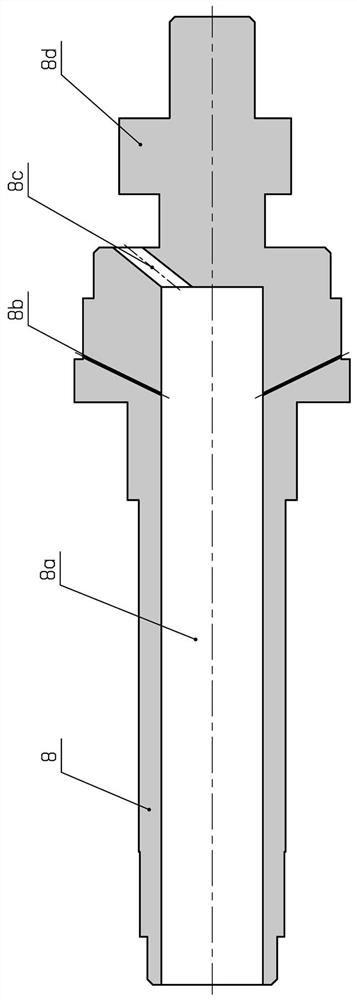

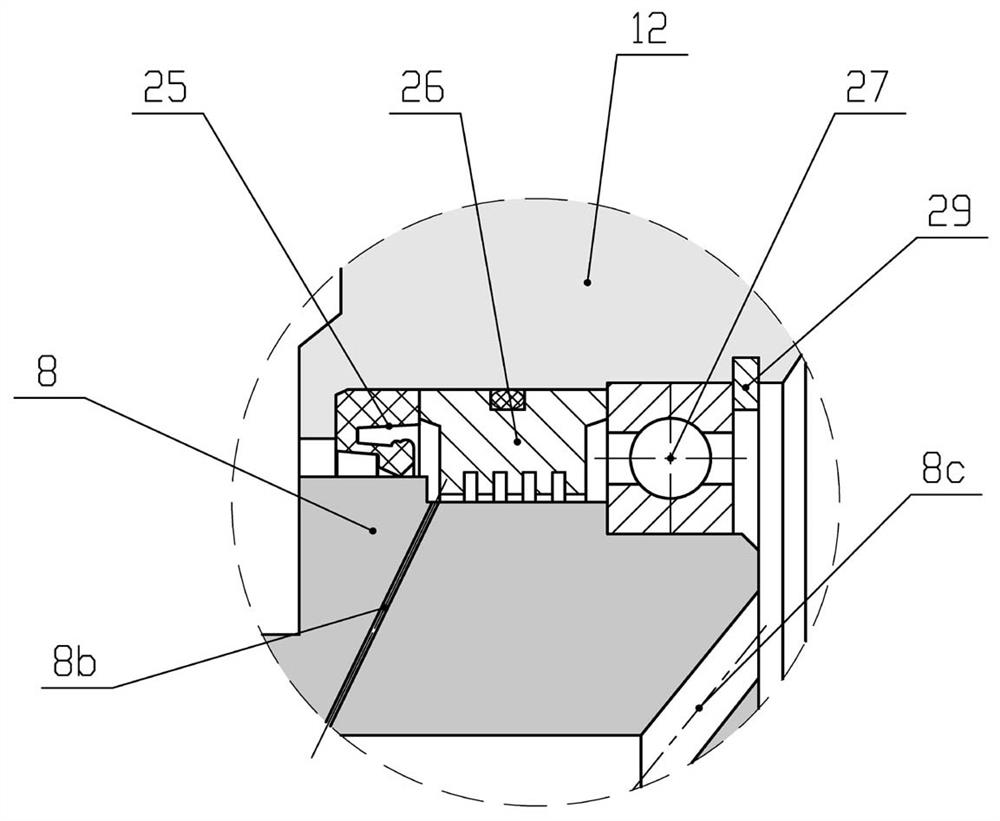

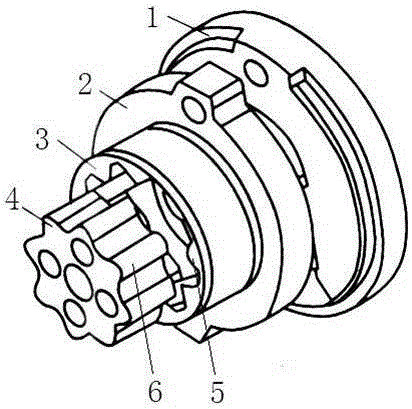

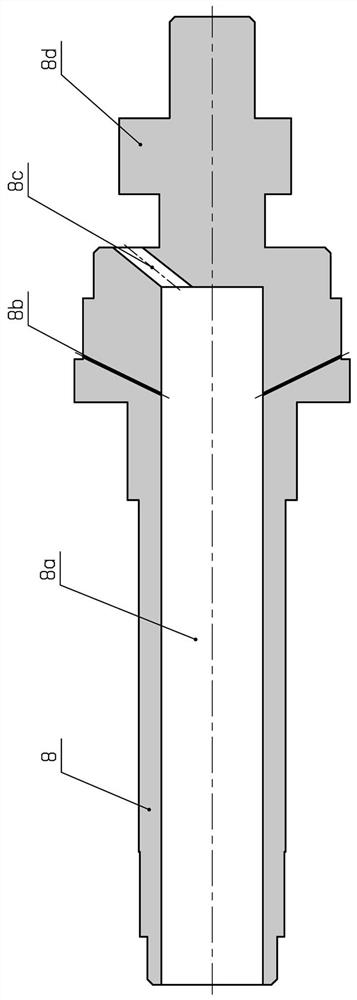

Digital variable hydraulic motor radial plunger pump

ActiveCN111946580ALarge adjustable range of displacementGood power adaptabilityPositive displacement pump componentsPump controlPhysicsElectric machinery

The invention discloses a digital variable hydraulic motor radial plunger pump. A motor rotor (15) is arranged on a hollow composite shaft (8) in a hot sleeving mode and supported in a shell (12) through bearings (19 and 27), and a sealing ring (20), a sealing ring (26) and a lip-shaped sealing ring (25) are arranged on the two sides of each bearing; a ball plunger (5) and a sliding shoe (6) are rolled into a whole and are in spherical hinge connection, the axis of the ball plunger (5) is perpendicular to the axis of the hollow composite shaft (8), the sliding shoe (6) is in contact fit with an eccentric disc (8c) on the hollow composite shaft (8), and when the eccentric disc (8c) rotates along with the hollow composite shaft (8), the ball plunger (5) and the sliding shoe (6) are driven tomove in corresponding plunger holes (10c) formed in a pump body (10) and reset under the action of a reset spring (4); and the axis of a digital switch oil suction one-way valve (1) coincides with the axes of the plunger holes (10c), and an oil discharge one-way valve (3) is arranged perpendicular to an electromagnetic switch oil suction one-way valve (1).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

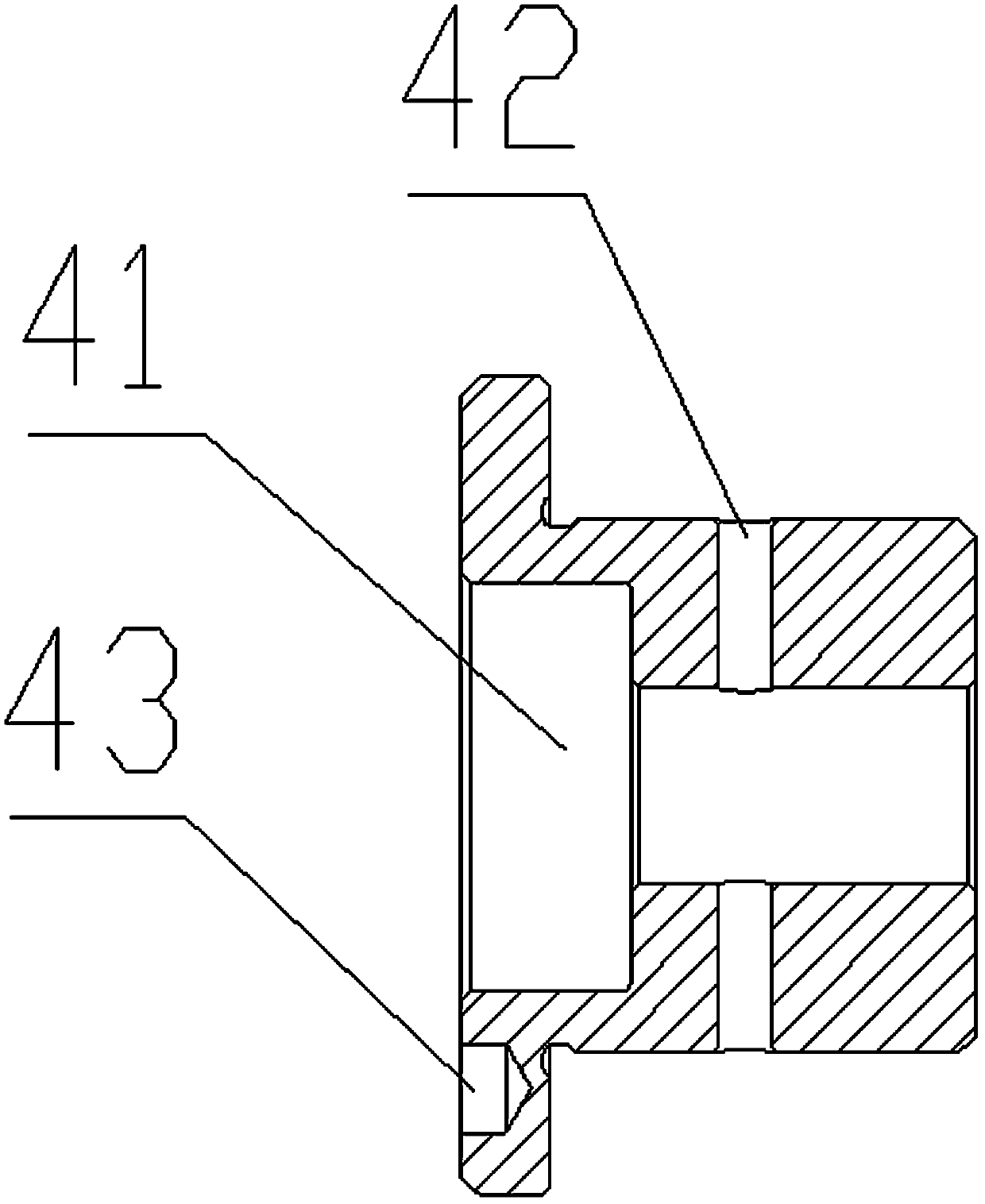

Electrically-driven gear transmission plunger pump

PendingCN109281813ALow costClever combinationPumpsMechanical energy handlingElectricityLinear motion

The invention discloses an electrically-driven gear transmission plunger pump. The electrically-driven gear transmission plunger pump comprises a motor, a small-tooth-difference speed reducing transmission mechanism and a plunger pump body, the input end of the small-tooth-difference speed reducing transmission mechanism is connected with an output shaft of the motor, and the output end of the small-tooth-difference speed reducing transmission mechanism eccentrically rotates and is connected with a plunger pump core in the plunger pump body to drive the plunger pump core to do vertical reciprocating linear motion in the plunger pump body. Therefore, the motor, the speed reducing mechanism and the plunger pump body are combined to complete mechanical-electrical-hydraulic integration, advantages and disadvantages are complementary, the structures are skillfully combined, parts are reduced, the cost is reduced, the functions are integrated, application is convenient, and the application range field is greatly widened; the structure is compact, the size is small, and the position precision is high; and the small-tooth-difference speed reducing transmission mechanism skillfully drives the plunger pump core to do reciprocating motion, a tedious output mechanism is omitted, the industry model selection and product development process is greatly and professionally shortened, and the electrically-driven gear transmission plunger pump is especially suitable for vehicles, air vehicles, small robot fixtures and the like.

Owner:温州市基安机械有限公司 +1

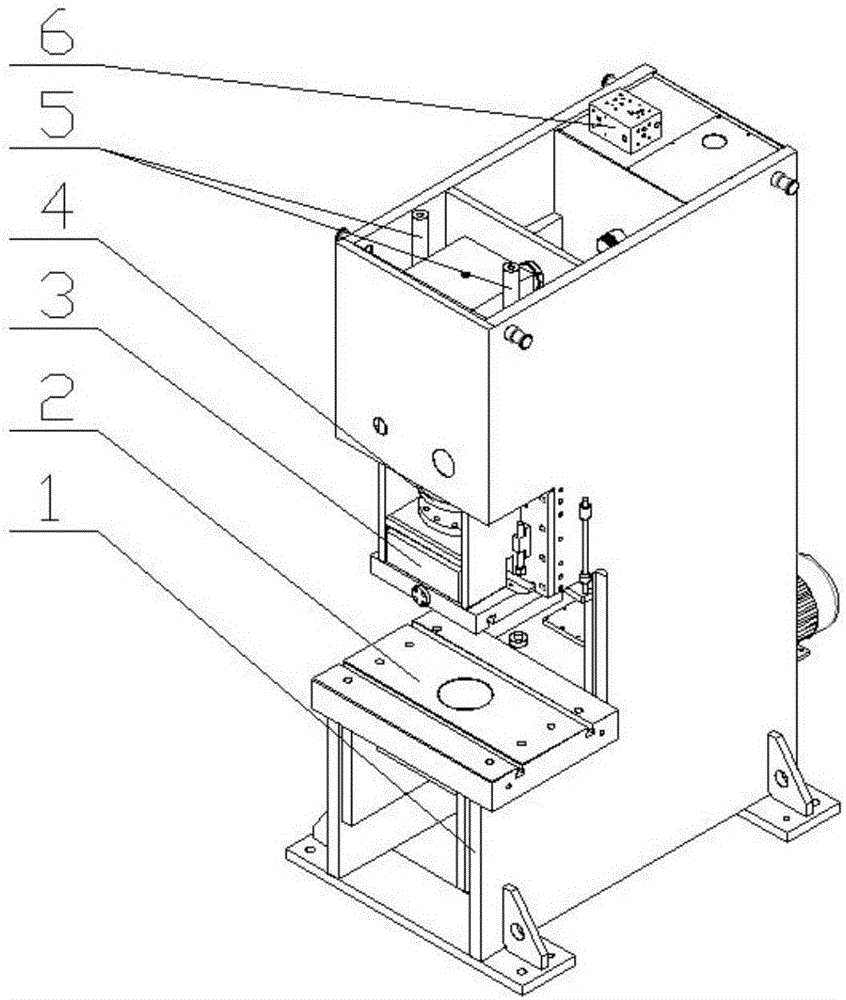

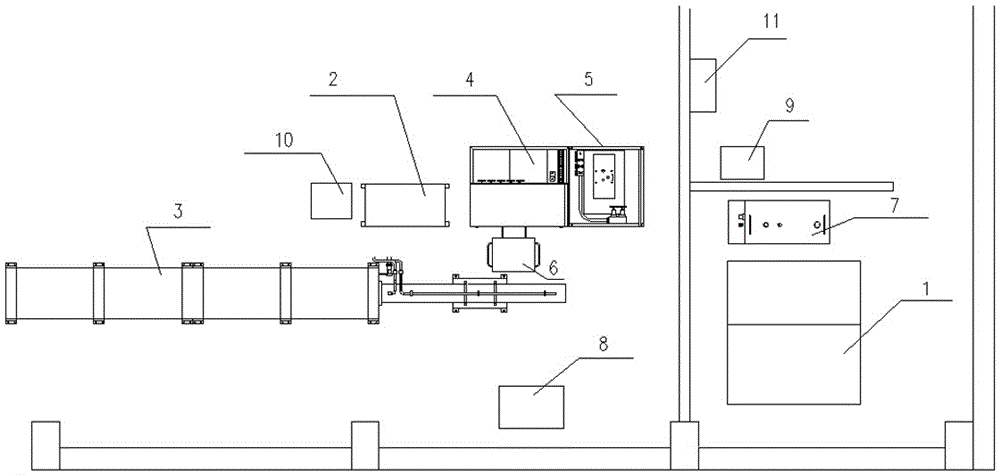

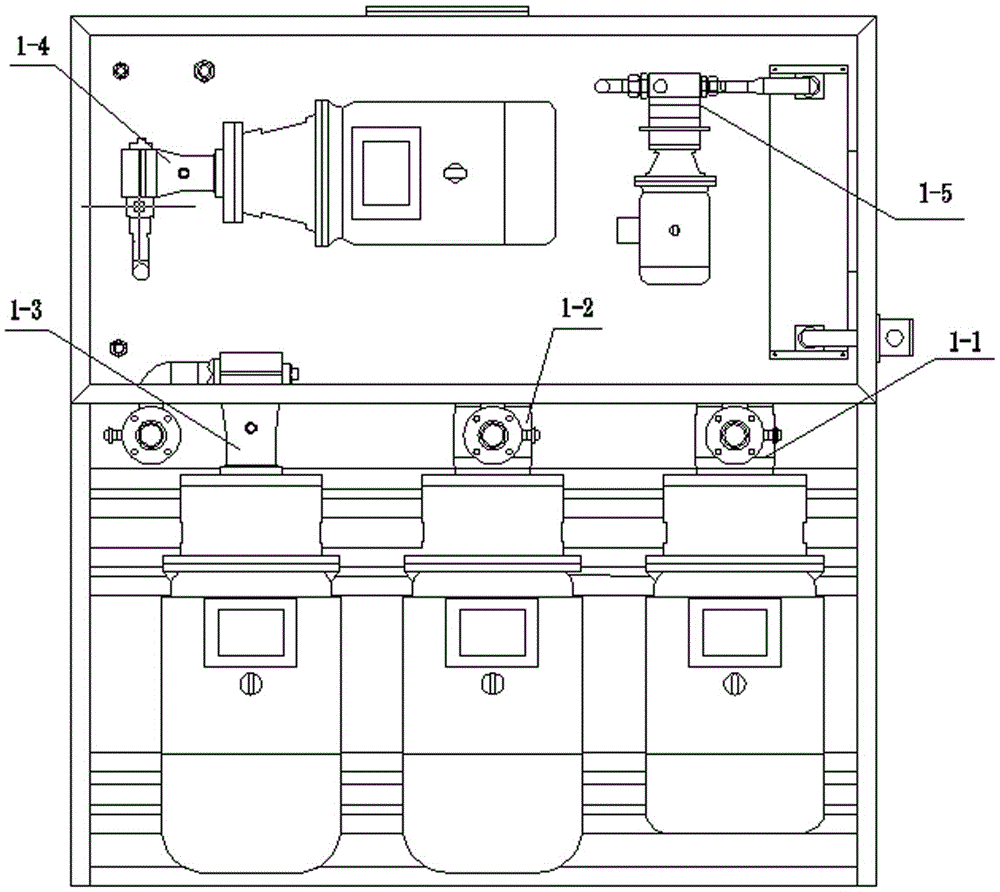

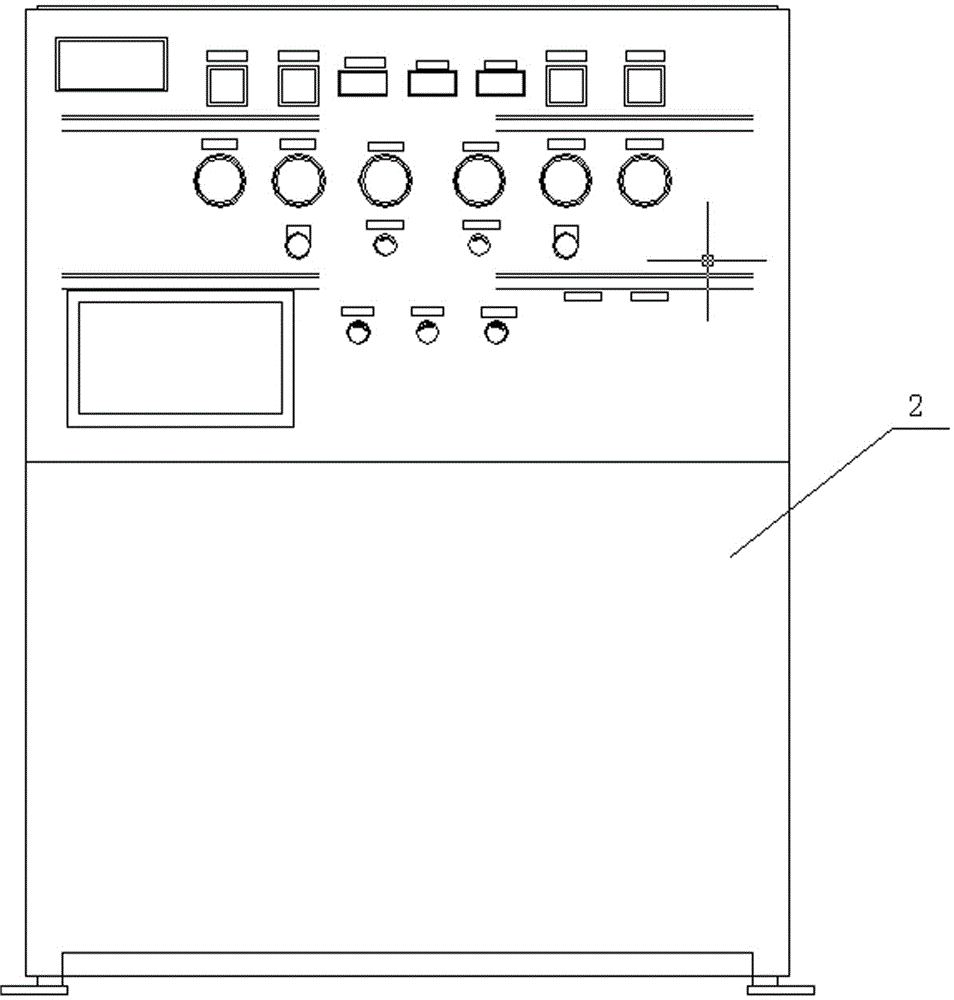

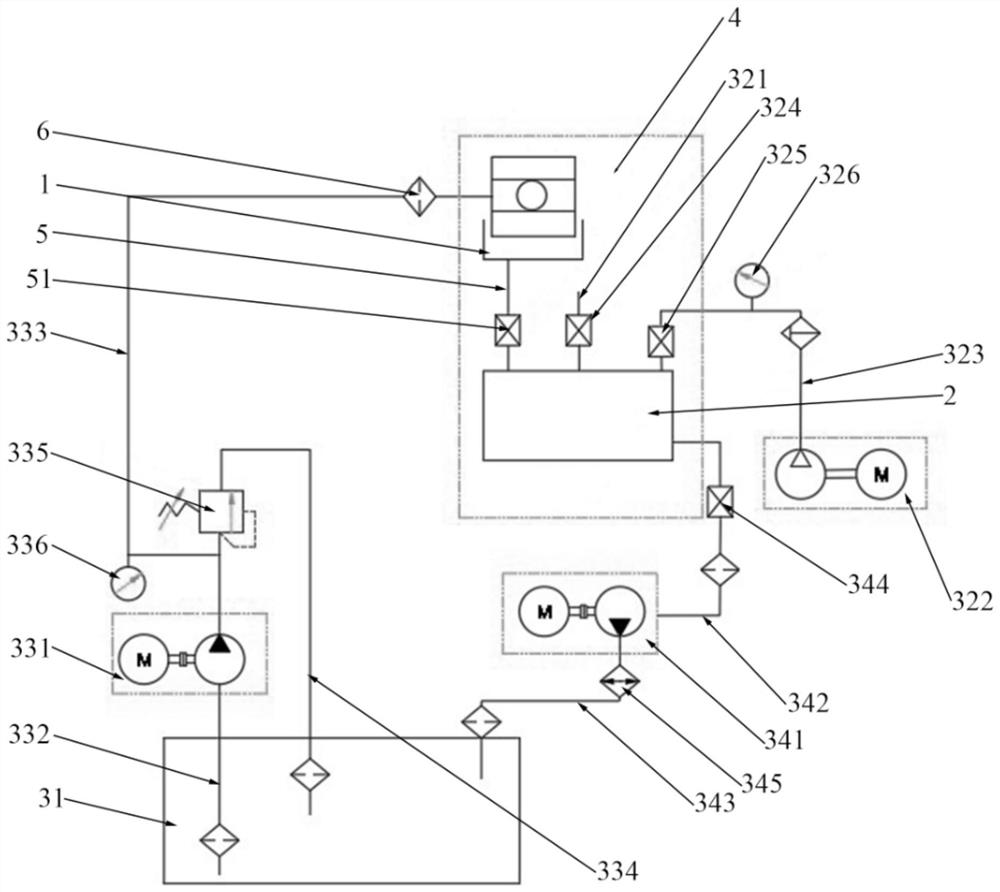

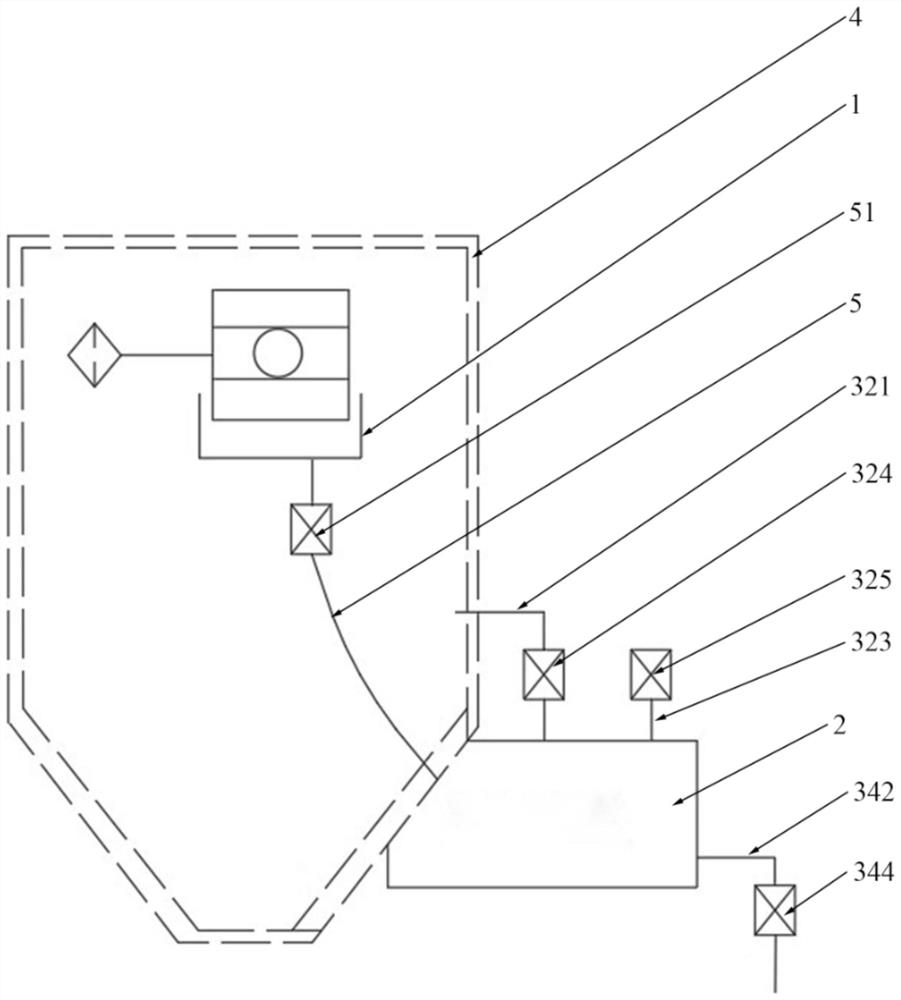

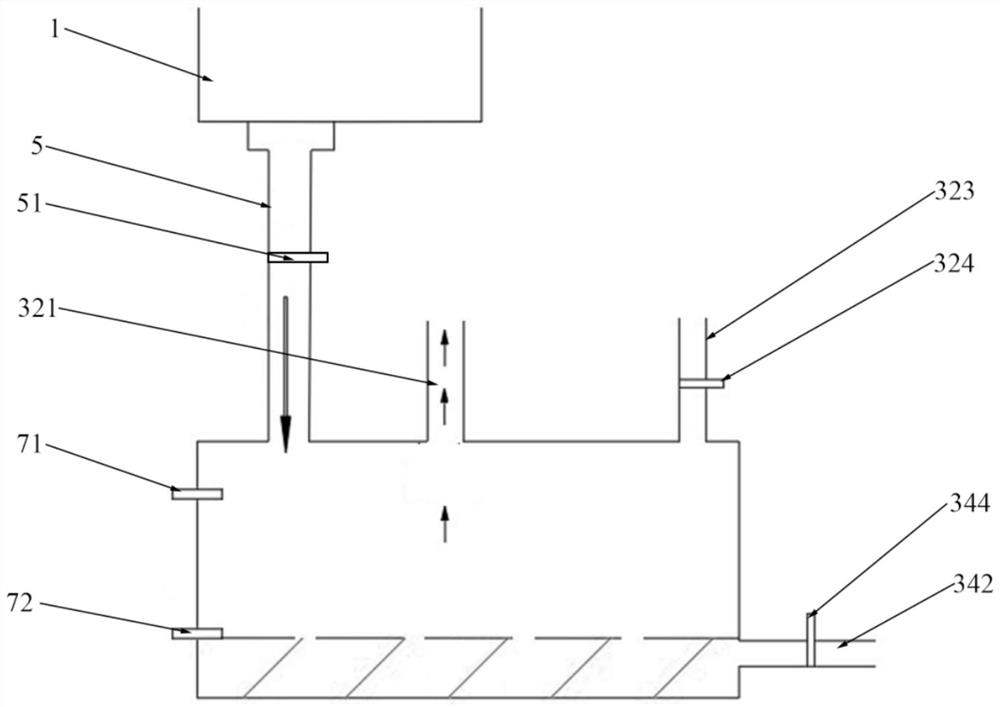

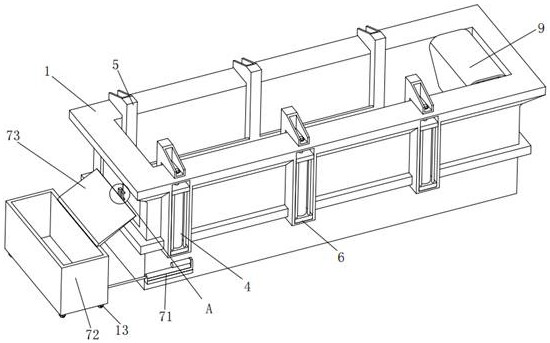

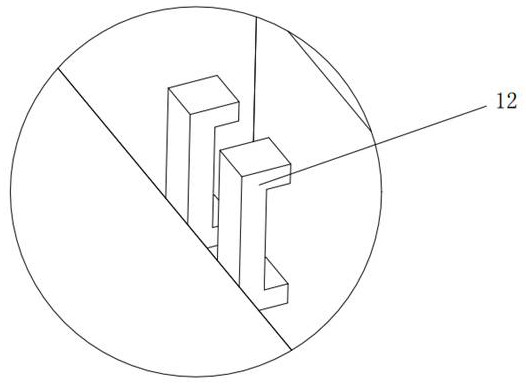

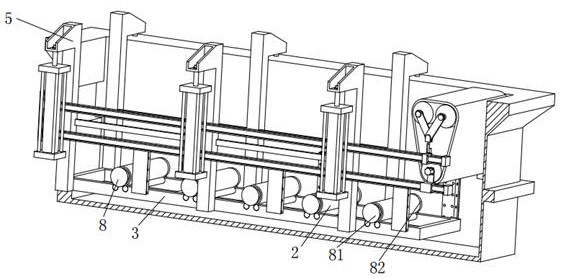

A heavy-duty mining dump truck hydraulic cylinder/hydraulic valve test bench

ActiveCN103352900BRealize stepless adjustmentEasy accessFluid-pressure actuator testingElectricityFuel tank

The invention relates to a heavy-duty mining dump vehicle hydraulic oil cylinder / hydraulic valve test table. The heavy-duty mining dump vehicle hydraulic valve test table comprises a power oil source portion, an oil cylinder test operation table, an oil cylinder supporting rack, a valve test operation table, a valve-to-be-tested installation rack, a flow measuring trolley, a waste oil collecting oil tank, a power cabinet, a PLC cabinet body, an electric control operation cabinet and an industrial personal computer. The power oil source portion is connected with the valve test operation table and the oil cylinder test operation table through different oil pipes respectively. The valve test operation table is arranged at one side of the valve-to-be-tested installation rack. The flow measuring trolley is connected with the valve test operation table or the oil cylinder test operation table. The oil cylinder supporting rack is connected with the waste oil collecting oil tank through an oil pipe. The oil cylinder test operation table and the valve test operation table are respectively and electrically connected with the electric control operation cabinet. The electric control operation cabinet is electrically connected with the industrial personal computer. The heavy-duty mining dump vehicle hydraulic oil cylinder / hydraulic valve test table are simple and compact in structure, beautiful, tidy, good in integration, convenient to control and reliable in testing.

Owner:HUNAN XD HEAVY EQUIP

Self-deoiling adhesive and production process thereof

InactiveCN113025232AGood adhesionFull oil absorptionMacromolecular adhesive additivesAlkali metal oxides/hydroxidesAdhesive cementPolymer science

The invention discloses a self-deoiling adhesive and a production process thereof, and belongs to the field of adhesive processing and production. The self-deoiling adhesive comprises an adhesive body, a plurality of deoiling balls distributed randomly are mixed in the adhesive body, built-in balls are placed in the deoiling balls, and oil-absorbing fillers are packed between the deoiling balls and the built-in balls. According to the scheme, the oil removal balls capable of automatically absorbing oil are added into an existing adhesive, so that oil on the surface of a metal structural part is absorbed, the trouble that oil stains are cleaned before the adhesive is smeared is omitted, when the adhesive is smeared, the oil removal balls moves towards the bonding surface under the adsorption effect of magnet on a magnetic fluid, the oil removal balls fully absorbs oil, the oil removal balls after oil absorption sinks into the adhesive through the weight change, the adhesive can be better bonded with the metal structural part, and the bonding effect of the adhesive is effectively improved. Compared with existing adhesives, the adhesive disclosed by the invention saves the trouble of cleaning greasy dirt, and the bonding strength is effectively improved.

Owner:贾童童

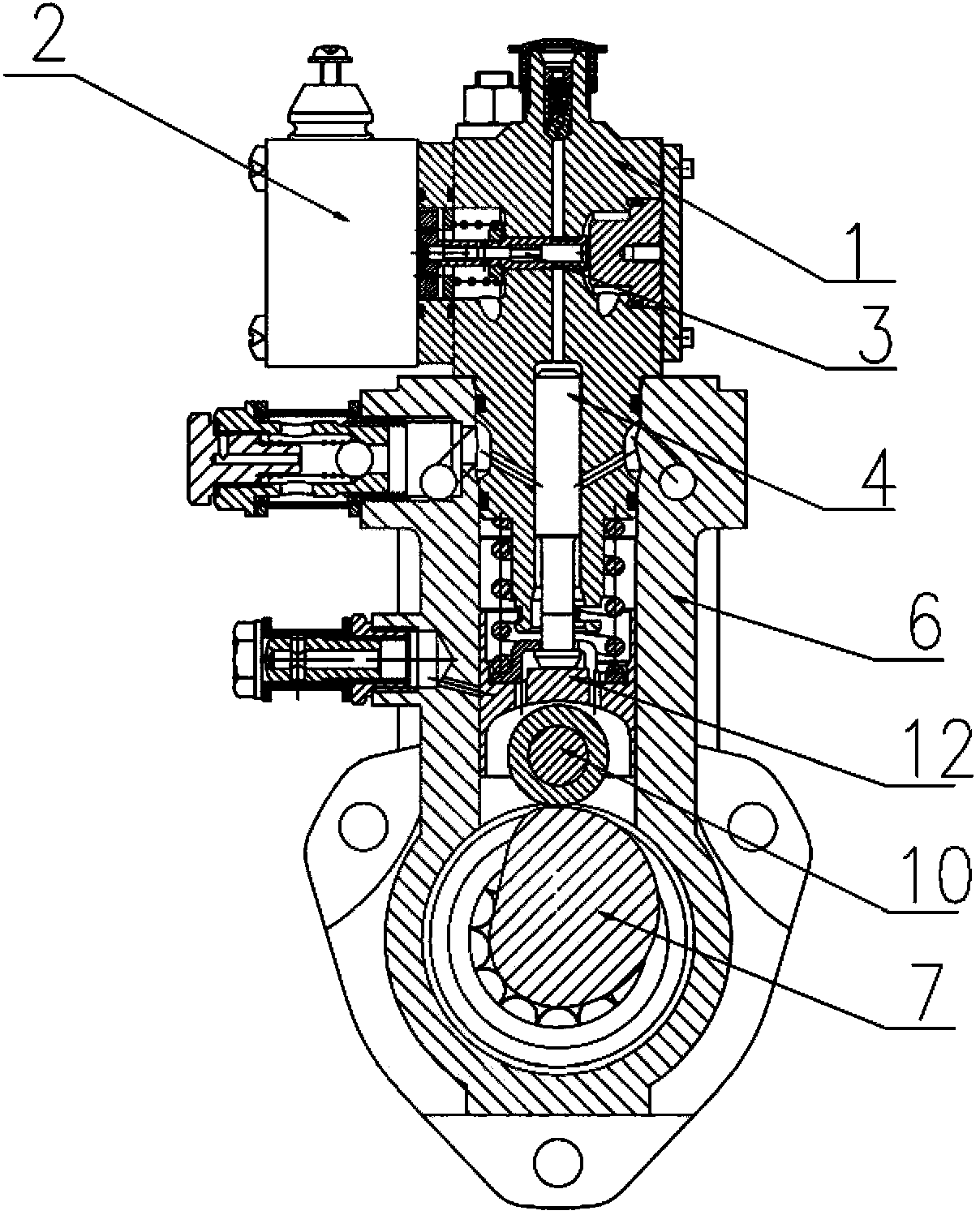

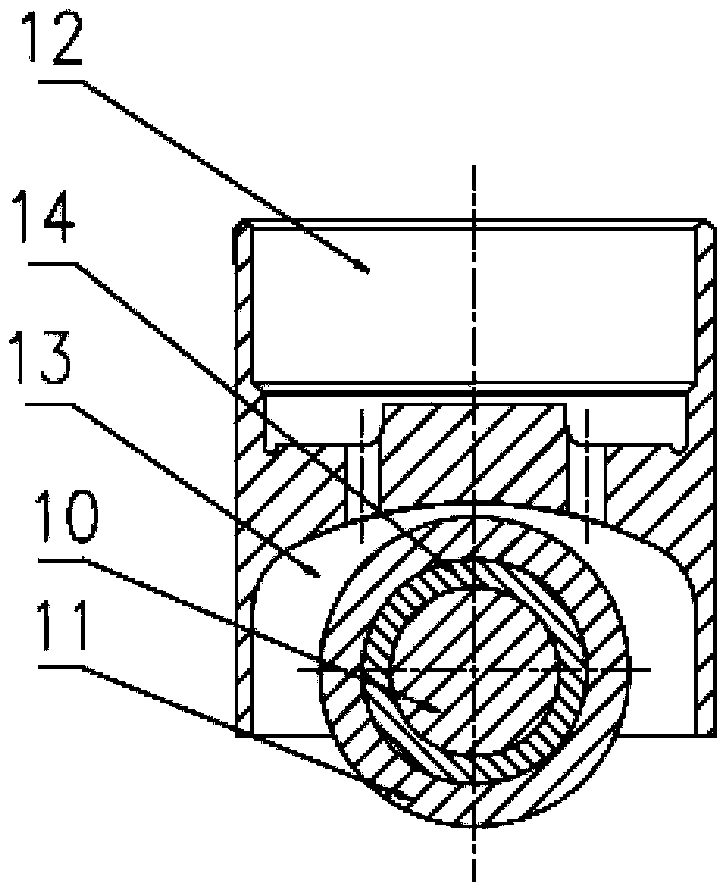

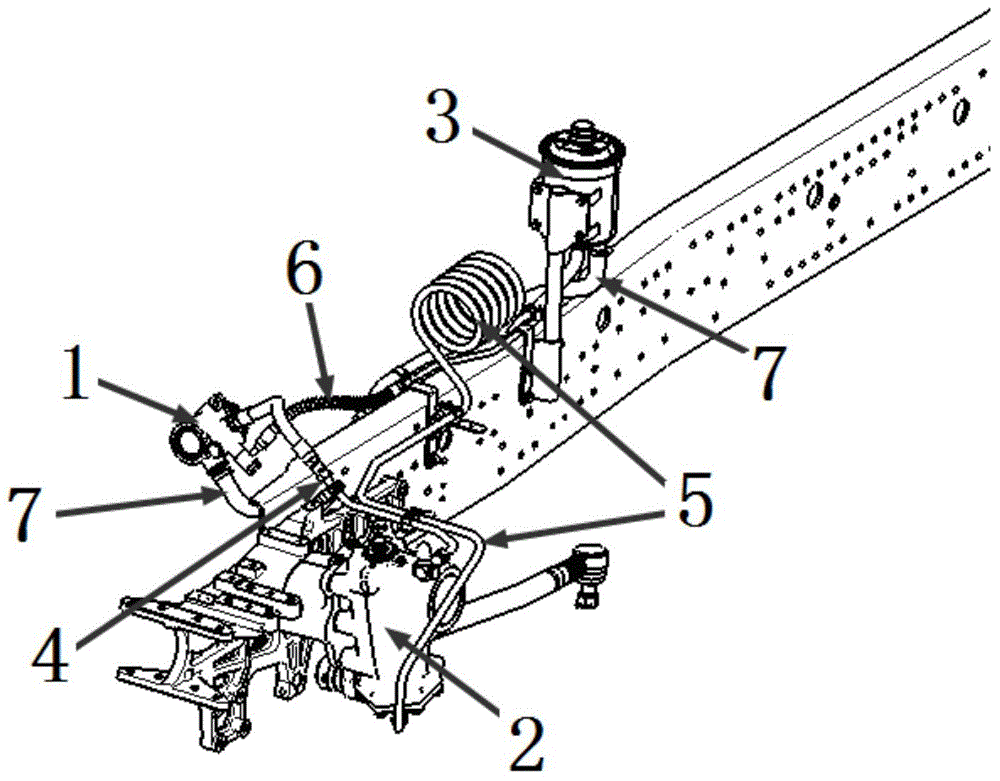

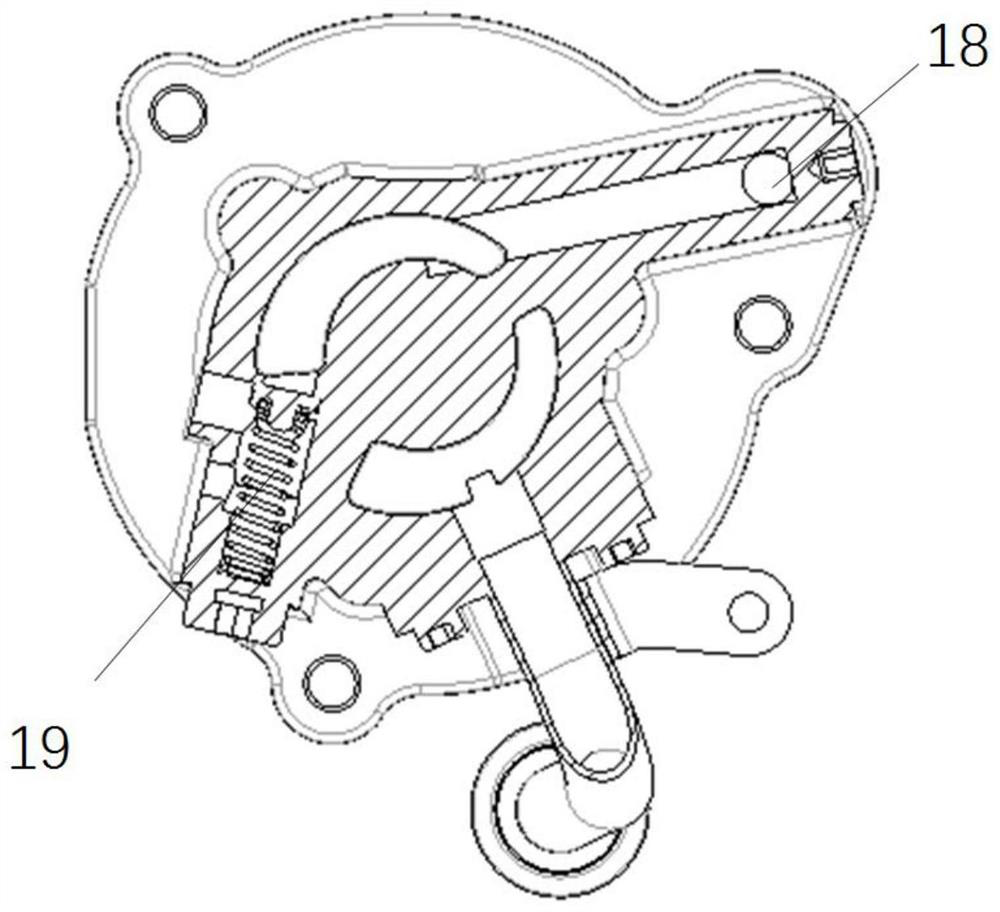

Hydraulic power steering pump and steering system thereof

InactiveCN104129427AFull oil absorptionReduce temperature riseFluid steeringHigh pressurePower steering

The invention discloses a hydraulic power steering pump and a steering system thereof. An overflow valve is arranged in the steering pump, an overflow opening is formed in the wall of a cavity body of the steering pump at the position corresponding to the overflow valve, the overflow opening is communicated with an oil suction chamber in the steering pump through an oil passage in the steering pump, and the end opening of the overflow opening is connected with an overflow pipe which is used for being communicated with a steering oil tank. The steering system comprises a steering gear and the steering oil tank, wherein an oil return opening of the steering gear is connected with the steering oil tank through an oil return pipe. The steering system also comprises the hydraulic power steering pump, the steering oil tank is connected with an oil inlet of the steering pump through an oil suction pipe, an oil outlet of the steering pump is connected with the steering gear through a high-pressure oil pipe, and the overflow opening of the steering pump is connected with the steering oil tank through the overflow pipe. On the condition of high rotating speed, a part of overflowing hydraulic oil flows through the inner part of the steering pump to be directly applied to the next circulation, and the other part of the overflowing hydraulic oil flows back to the steering oil tank through an outer oil pipe to be again applied to the circulation, so that sufficient oil suction on the condition of high rotating speed is ensured, and the temperature rise is relatively small.

Owner:WUHU KAIKING TECH

An automatic forming machine for peach crisp mung bean cake

ActiveCN110771646BFull oil absorptionExtended shelf lifeDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusMolding machineAgricultural engineering

The invention discloses an automatic forming machine for peach crisp and mung bean cake, which comprises a feeding mechanism and a forming mechanism. Both sides of the inside are provided with feeding compression winches and feeding winches. A connecting pipe is welded at the front end of the fabric compression chamber. The front end of the connecting pipe is connected to the feeding nozzle, and the feeding nozzle is connected to the forming mechanism. There is a blank transition channel on the frame, a blank forming part is provided at the front end of the blank transition channel, a transverse cutting material stopper is provided on the forming frame, a bracket is provided on the forming frame, and a bracket is provided on the support. There are first and second forming cylinders, and forming pressing plates and forming molds are arranged at the lower end of the first and second forming cylinders. The invention has simple structure and reasonable design, can satisfy the production of peach cakes and mung bean cakes at the same time, can also improve the crispness of peach cakes, and the produced mung bean cakes are not easy to break.

Owner:谭爱平

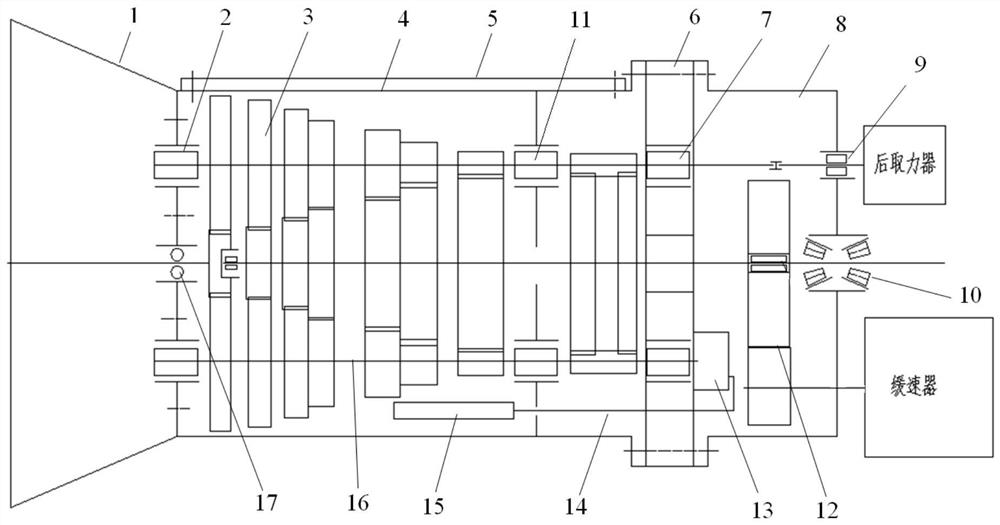

A transmission lubricating cooling system

ActiveCN113007332BExtended service lifeMeet the lubrication temperature requirementsGearboxesGear lubrication/coolingEngineeringLubrication

The invention provides a transmission lubricating and cooling system, aiming at solving the problem of insufficient lubrication, reduced service life of the transmission, high risk of oil leakage, inconvenient installation, large loss of oil passage and high efficiency of the oil pump in the transmission lubrication of the existing single box three countershaft structure. lower question. The system adopts oil pump pressure lubrication, and realizes the lubrication of the upper lubrication points of the three-countershaft transmission through the combination of the casing oil passage and the oil pipe. At the same time, a strong cooling interface is reserved at the beginning of the oil passage, and a forced cooling system can be connected externally to control the transmission oil. Temperature within a reasonable range, prolong the service life of oil and transmission.

Owner:SHAANXI FAST GEAR CO

A buoyancy drive device based on the adjustment of marine environment parameters

ActiveCN109591988BEasy to adjustQuantitative adjustmentBuoysUnderwater vesselsMathematical modelMarine engineering

The invention provides a buoyancy driving device for adjusting marine environment parameters, which belongs to the field of marine engineering. The device can realize precise and quantitative adjustment of buoyancy. Including: hydraulic-pneumatic combination drive module, marine environment perception module and computing control module; among them, each sensor in the marine environment perception module can measure the parameters such as temperature, salinity and depth of seawater in real time, and the computing control module can collect the above measurement data , combined with the mathematical model of system motion preset in the built-in program of the calculation control module and the mathematical model of seawater density, the buoyancy to be adjusted is calculated, and then the calculation control module controls the action of the electrical equipment in the hydraulic-pneumatic combination drive module to realize buoyancy adjustment . The invention has a high degree of integration, can realize accurate and quantitative buoyancy control according to changes in environmental parameters, and has a reliable system.

Owner:CSIC NO 710 RES & DEV INST

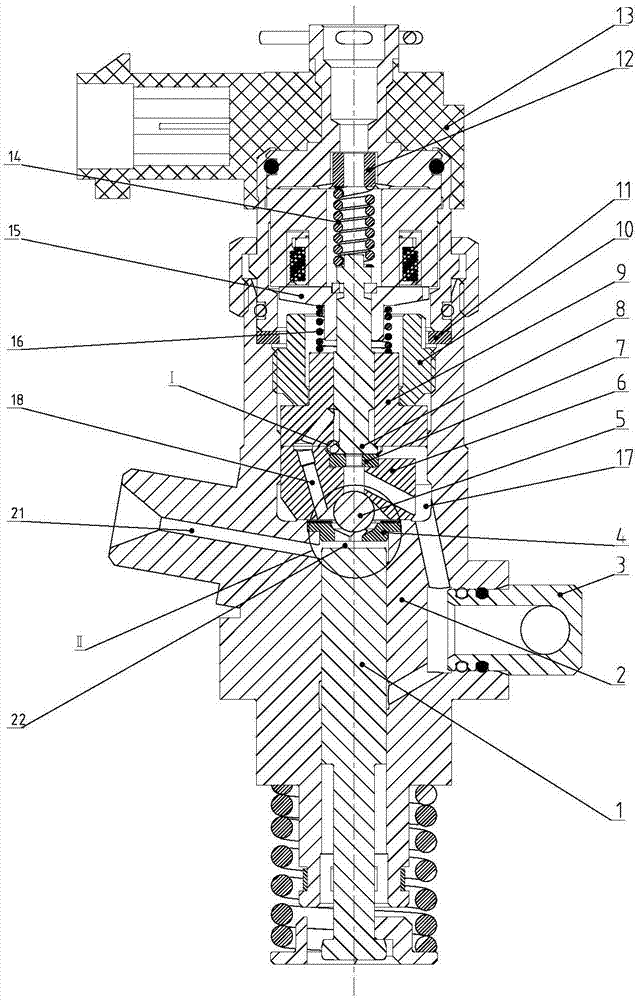

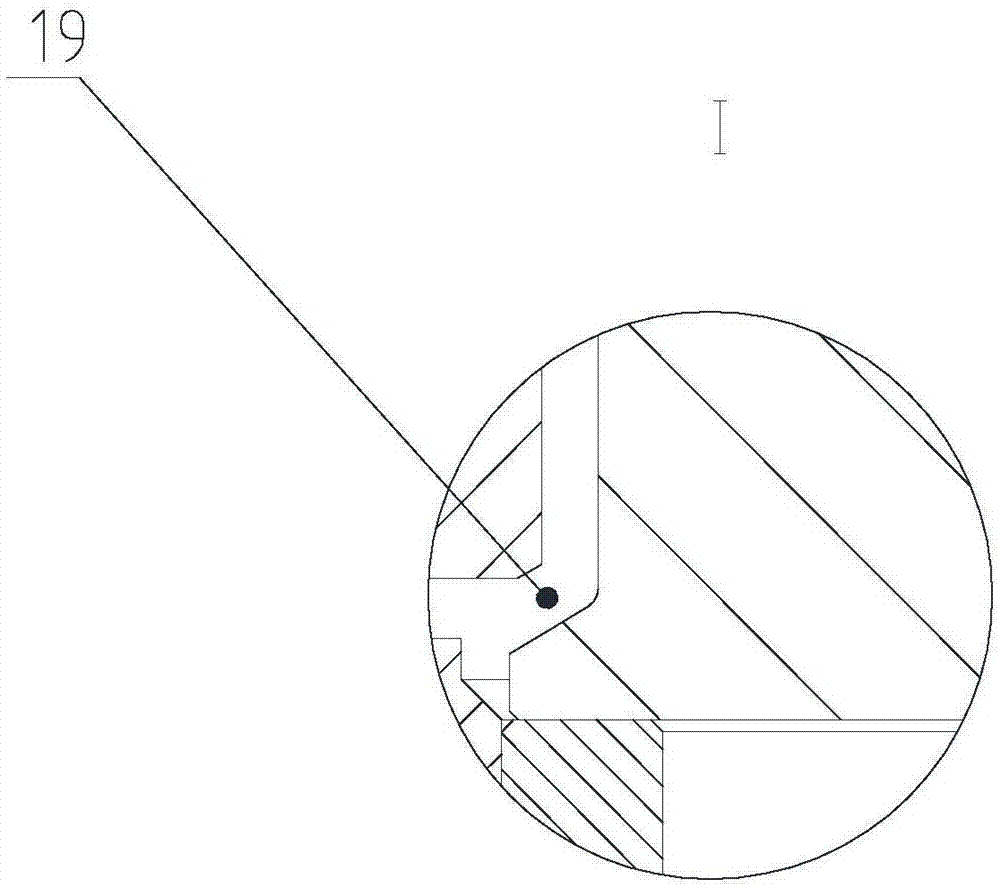

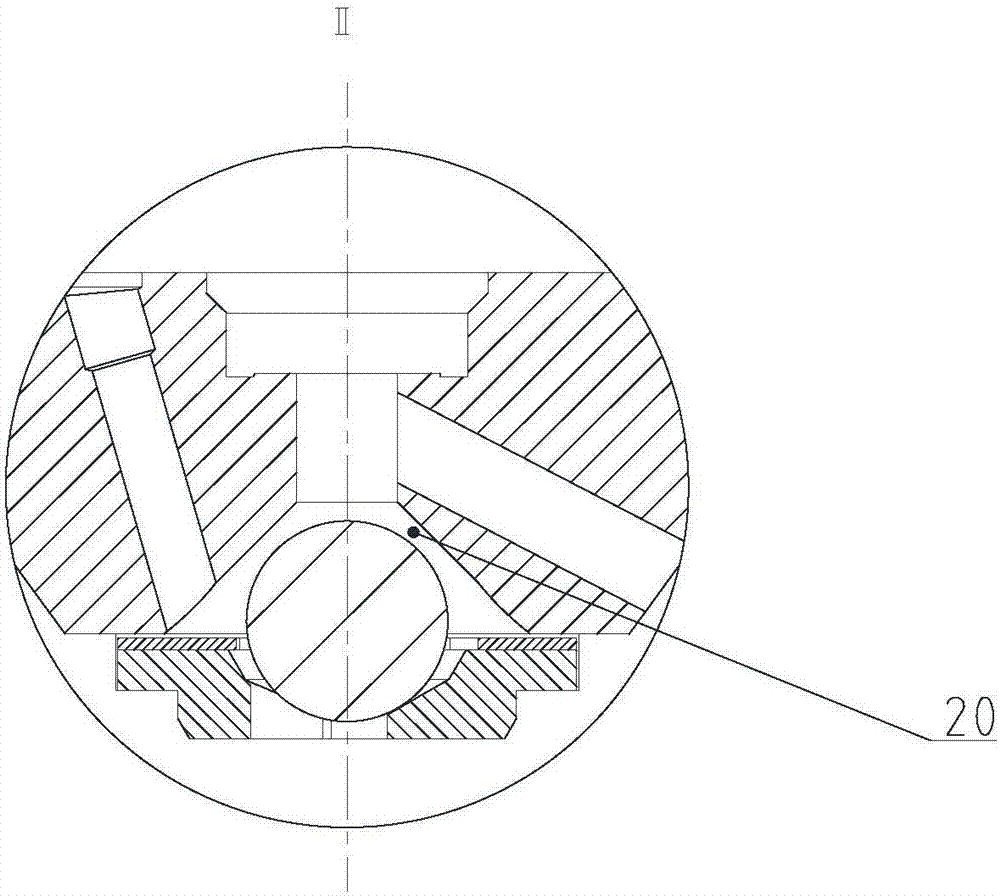

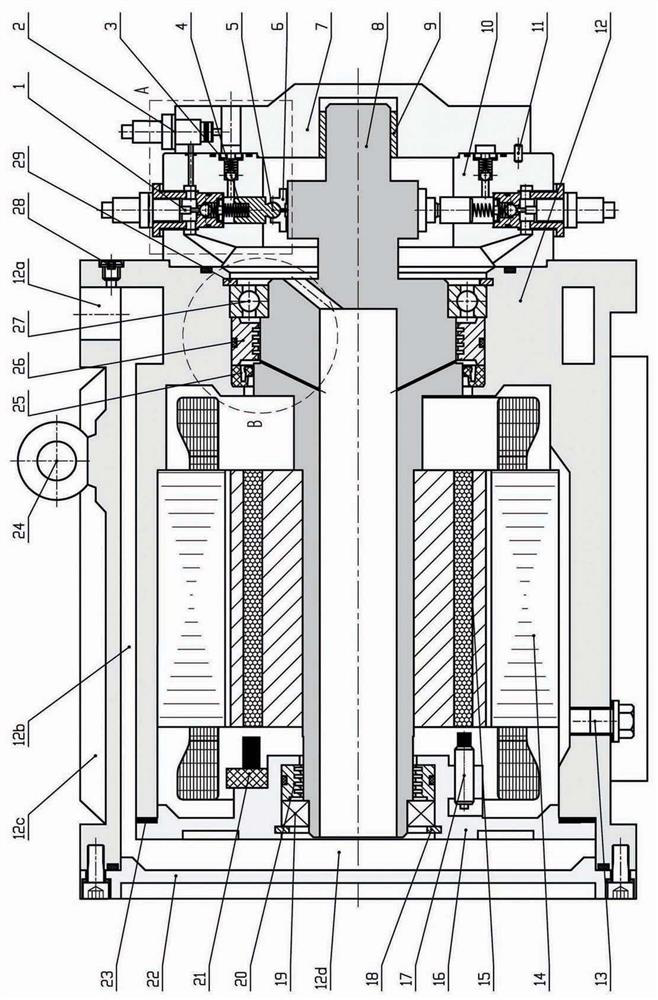

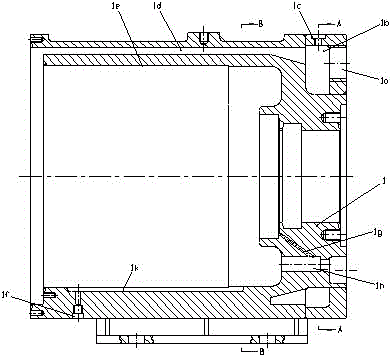

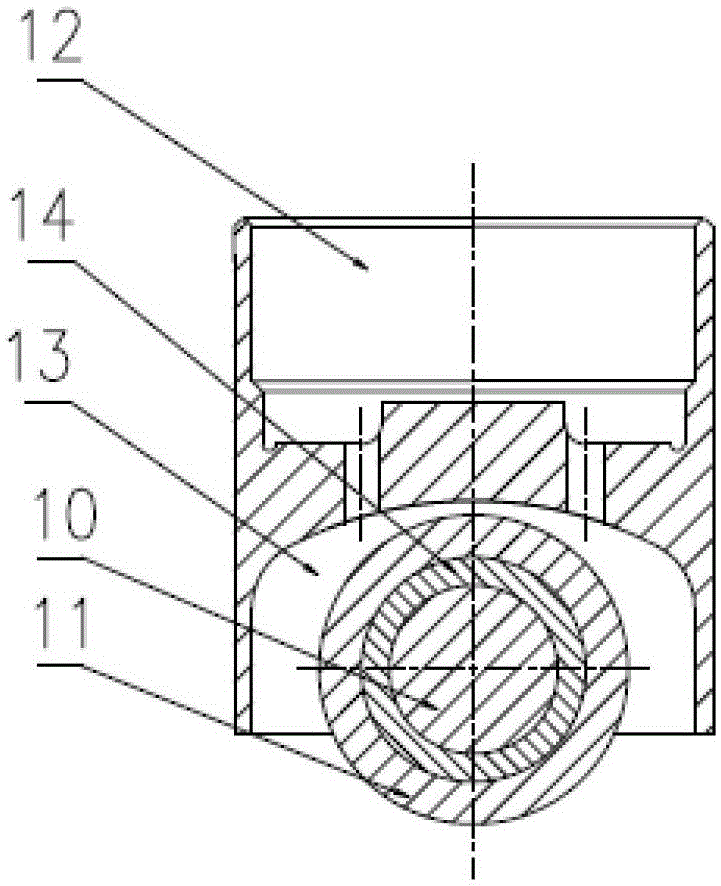

An air gap non-immersed hydraulic motor vane pump

ActiveCN103047134BImprove efficiencyImprove sealingMachines/enginesRotary/oscillating piston pump componentsHydraulic motorCavitation

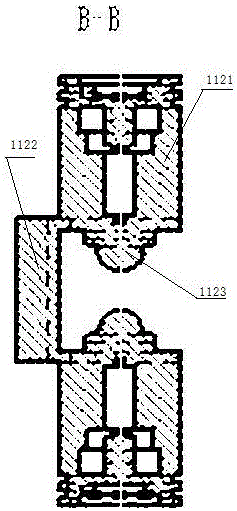

The invention relates to a non-oil-immersed air gap type hydraulic motor vane pump. A motor rotor (3) and a main shaft (4) are compressed together, and are supported on a shell (1) and an inner end cover (23) by a first bearing (5) and a second bearing (25), a pump core (12) of the vane pump is connected with the main shaft (4) by a spline (4c), the pump core (12) of the vane pump is arranged in a pump core holder (13), a motor stator (2) is pressed in an inner hole (1e) of a shell (1), the shell (1) is provided with an oil inlet (1a), an annular flow channel (1b) and a cooling flow channel (1d), and the main shaft (4) is provided with a central hole (4a) of the main shaft and a pore plate centrifugal pump (4c). The heat generated by a motor and the like is taken away by oil flowing in a motor pump, the fan in the motor is saved, and meanwhile, the hydraulic motor vane pump can absorb oil and enhance the pressure by the central hole of the main shaft and the pore plate centrifugal pump. The aerodynamic noise and the cavitation noise are eliminated, so that the entire hydraulic motor vane pump has a favorable silencing performance.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Cycloid rotor pump of sewing machine

InactiveCN105201818AReduce in quantitySlow down the sliding speedRotary piston pumpsLubricating pumpsEngineeringLubrication

The invention discloses a cycloid rotor pump of a sewing machine. The cycloid rotor pump comprises a base and is characterized by further comprising a pump body, an inner rotor and an outer rotor, wherein the base is round and is hinged to the pump body through screws, the outer rotor is arranged on the pump body and can move in the pump body freely, inner teeth are arranged on the inner side of the outer rotor, outer teeth are arranged on the outer side of the inner rotor, the inner teeth and the outer teeth can be partially meshed, and the inner teeth is one less than the outer teeth. The cycloid rotor pump of the sewing machine solves problems that quick and effective lubrication cannot be realized, usage of sewing machines is affected, parts of the sewing machines are abraded quickly and service lives of the sewing machines are greatly shortened due to the fact that the sewing machines suck and discharge lubrication oil in a very troublesome manner in the prior art, is simple in structure, convenient to use and lower in noise and can suck and discharge the oil relatively fully, and oil flows stably.

Owner:SUZHOU KERUN WEAVING

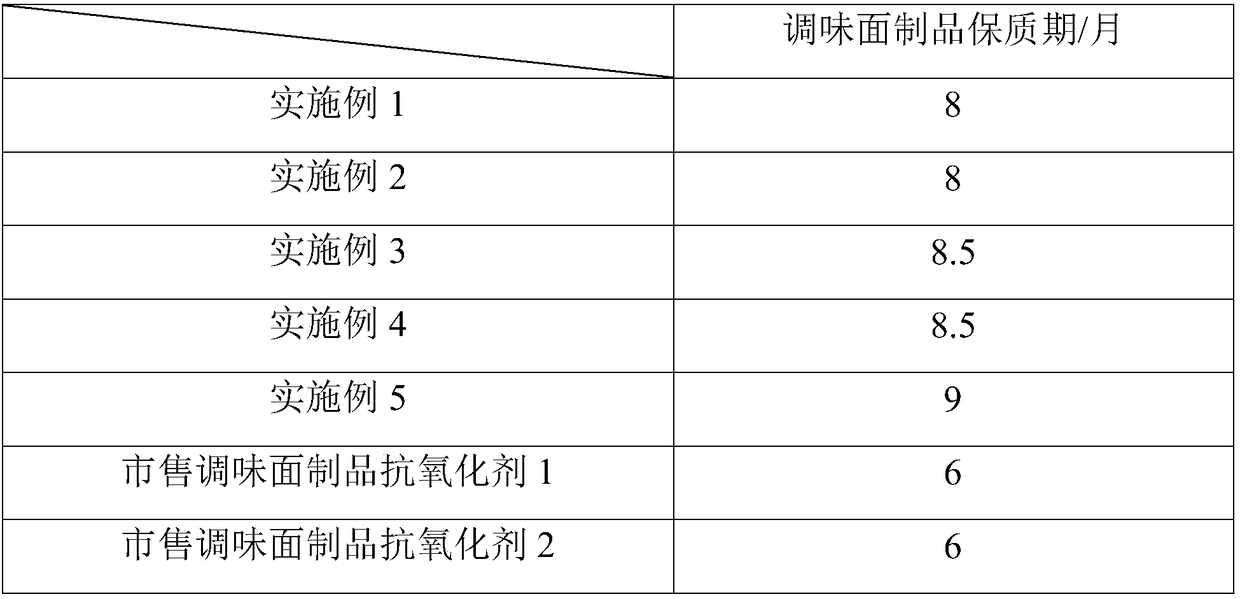

Seasoned flour product antioxidant and preparation method thereof

InactiveCN108464429AImprove antioxidant capacityEnhanced inhibitory effectFood ingredient as antioxidantClimate change adaptationBetacyaninsAdditive ingredient

The invention provides a seasoned flour product antioxidant and a preparation method thereof. The seasoned flour product antioxidant comprises the following ingredients in parts by weight: 10-15 partsof dahurian rose seed procyanidin, 10-15 parts of tea polyphenols, 10-20 parts of tea polysaccharides, 50-80 parts of porous starch, 5-10 parts of sodium isoascorbate, and 20-40 parts of citric acid.Compared with conventional flour product antioxidants, the antioxidant disclosed by the invention is capable of greatly prolonging shelf lives of seasoned flour products that the shelf life can be prolonged from 6 months to 9 months.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Oil source system of vibration test device suitable for vacuum environment

PendingCN114659741AReduce the impactLarge test areaVibration testingFluid-pressure actuator componentsThermodynamicsTest chamber

The invention discloses an oil source system of a vibration test device suitable for a vacuum environment, the interior of a test box is a vacuum environment, an oil pool piece is located in the test box, the pressure in the oil pool piece is smaller than the external atmospheric pressure, and oil in an oil tank enters the oil pool piece under the action of an oil supply assembly; the gas circuit assembly has a state that the test box is communicated with the oil storage part, that is, when the test box is communicated with the oil storage part, the gas pressure in the oil storage part and the gas pressure in the test box slowly tend to be consistent, and oil in the oil pool part enters the oil storage part under the action of gravity; when the gas path assembly conveys gas into the oil storage piece, the gas pressure in the oil storage piece is increased until the oil return assembly can work normally, oil in the oil storage piece returns to the oil tank through the oil return assembly, and circulation is completed.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR +1

Industrial wastewater surface oil stain removal pool

ActiveCN114477371AComprehensive degreasingStrong integrityFatty/oily/floating substances removal devicesEnergy based wastewater treatmentProcess engineeringEnvironmental geology

The invention discloses an industrial wastewater surface oil stain removal pool, and relates to the technical field of wastewater treatment. Comprising a deoiling pool and a workpiece, and further comprises a lifting frame, an air cylinder, a jacking frame, a plurality of storage grooves, a pollution discharge assembly, a fixing assembly, an oil suction assembly, a heating pipe and a pipe cover, the lifting frame is arranged at the bottom of the deoiling pool, and the storage grooves are formed; the distance between two first winding drums is adjusted through cooperation of a hinge block, a first electric push rod, an oil absorption felt and two hinge plates, and a first lead screw sliding table and a second lead screw sliding table are matched, so that the oil absorption felt can absorb oil for dead corners of the side walls of the two ends of the deoiling pool, deoiling is more comprehensive, the situation that the dead corners cannot be deoiled for a long time is avoided, and the service life of the deoiling pool is prolonged. And through cooperation of a first electric push rod, a hinge block and two hinge plates, cleaning of an oil absorption felt by a pollution discharge assembly in the next step can be facilitated, and the integrity of the device is higher.

Owner:温州宪江防腐设备有限公司

An electronically controlled unit combination pump for light vehicle diesel engine

ActiveCN103410643BGuaranteed working lengthReduce weightFuel injection apparatusMachines/enginesEngineeringCam

The invention relates to the technical field of vehicle engine manufacturing, in particular to an electronic unit composite pump for light-vehicle diesels. The electronic unit composite pump for light-vehicle diesels comprises a composite pump body, an oil conveying pump, a camshaft, a plurality of electronic unit pumps, tappet body assemblies corresponding to the electronic unit pumps and a cam, and is characterized in that the electronic unit pumps are installed on the composite pump body and comprise unit pump bodies, a plunger, control valve elements and electromagnets installed on one sides of the unit pump bodies, the oil conveying pump is installed on one side of the composite pump body, the tappet body assemblies are arranged between the cam and the plunger and comprise tappets, rolling wheels and rolling wheel pins, and U-shaped cavities are formed in the ends where the tappets make contact with the rolling wheels, wherein the plunger and the control valve elements are arranged in the unit pump bodies. The electronic unit composite pump for light-vehicle diesels has the advantages of being more compact in structure and capable of acquiring higher working speed so as to be matched with the high-speed diesels.

Owner:龙口龙泵柴油喷射高科有限公司

Digital Variable Hydraulic Motor Radial Piston Pump

ActiveCN111946580BImprove efficiencyFull oil absorptionPositive displacement pump componentsPump controlCircular discHydraulic motor

Digital variable hydraulic motor radial piston pump, the motor rotor (15) is shrunk on the hollow composite shaft (8), supported by bearings (19, 27) inside the casing (12), and sealing rings ( 20), sealing ring (26) and lip-shaped sealing ring (25); the ball plunger (5) and the sliding shoe (6) are rolled into one and connected by a ball joint, the axis of the ball plunger (5) and the hollow The axis of the compound shaft (8) is vertical, and the sliding shoe (6) is in contact with the eccentric disc (8c) on the hollow compound shaft (8). When the eccentric disc (8c) rotates with the hollow compound shaft (8), the drive ball The head plunger (5) and the sliding shoe (6) move in the corresponding plunger hole (10c) opened on the pump body (10), and reset under the action of the return spring (4); the digital switch oil suction check valve ( 1) Its axis coincides with the axis of the plunger hole (10c), and the oil discharge check valve (3) is arranged vertically to the electromagnetic switch oil suction check valve (1).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com