Making method of vegetarian special-shaped spicy gluten

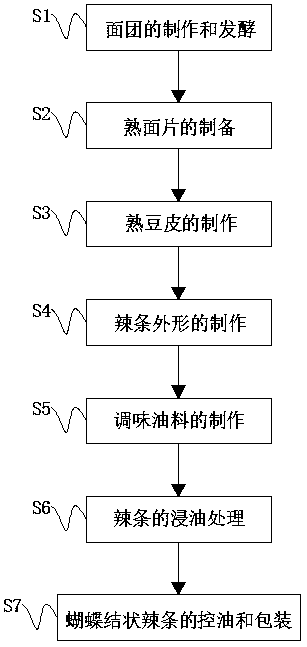

A production method and a technology for spicy strips, which are applied in the field of special-shaped vegetarian spicy strips, can solve problems such as harm to the health of consumers, poor taste of spicy strips, reduction of shape specificity of spicy strips, etc., meet taste requirements, ensure taste and taste, Satisfy the viewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] S1. Dough making and fermentation: first select 65 parts of flour in the corresponding ratio and pour it into the dough mixer, and add yeast and water in the corresponding ratio to the dough mixer, then start the dough mixer and stir the flour for 35 minutes until The flour turns into dough, and the surface of the dough is dusty, and has good toughness, then take the reconciled dough out of the dough mixer, put it in a fermentation tank and keep it sealed for 23 minutes, until the dough fermentation is completed;

[0031] S2, preparation of cooked noodles: the dough fermented in step S1 is cut into a plurality of small doughs by a cutting machine, and then the cut small doughs are extruded into dough sheets by a flattener, and the extruded dough sheet The thickness is 0.7cm, the length is 7cm, and the width is 4cm. After that, the dough is put into the boiler and steamed in boiling water for 22 minutes to get the cooked dough;

[0032] S3. Production of cooked bean curd...

Embodiment 2

[0038] S1. Dough making and fermentation: first select 60 parts of flour in the corresponding ratio and pour it into the dough mixer, and add yeast and water in the corresponding ratio to the dough mixer, then start the dough mixer and stir the flour for 30 minutes until The flour turns into dough, and the surface of the dough is dusty, and has good toughness, then take out the reconciled dough from the dough mixer, put it in a fermentation tank and keep it sealed for 20 minutes, until the fermentation of the dough is completed;

[0039] S2, preparation of cooked noodles: the dough fermented in step S1 is cut into a plurality of small doughs by a cutting machine, and then the cut small doughs are extruded into dough sheets by a flattener, and the extruded dough sheet The thickness is 0.5cm, the length is 5cm, and the width is 3cm. After that, the dough is put into the boiler and steamed in boiling water for 15 minutes to get the cooked dough;

[0040] S3. Production of cooked ...

Embodiment 3

[0046] S1. Dough production and fermentation: first select 70 parts of flour in the corresponding ratio and pour it into the dough mixer, and add yeast and water in the corresponding ratio to the dough mixer, then start the dough mixer and stir the flour for 40 minutes until The flour turns into dough, and the surface of the dough is dusty, and has good toughness, then take out the reconciled dough from the dough mixer, put it in a fermentation tank and keep it sealed for 25 minutes, until the fermentation of the dough is completed;

[0047] S2, preparation of cooked noodles: the dough fermented in step S1 is cut into a plurality of small doughs by a cutting machine, and then the cut small doughs are extruded into dough sheets by a flattener, and the extruded dough sheet The thickness is 1cm, the length is 8cm, and the width is 5cm. After that, put the noodles into the boiler and steam them in boiling water for 30 minutes to get cooked noodles;

[0048] S3. Production of cooke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com