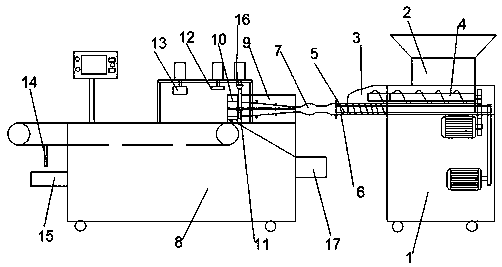

Automatic forming machine for walnut cakes and mung bean cakes

An automatic forming machine and forming machine technology, applied in dough forming and cutting equipment, dough embossing machine, dough sheeting machine/rolling machine/rolling pin, etc. The problems such as the decrease of crispness are solved, and the effect of simple structure, reasonable design and improved crispness is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to strengthen the understanding of the present invention, the present invention will be described in further detail below in conjunction with examples, which are only used to explain the present invention, and do not limit the protection scope of the present invention.

[0018] like figure 1 Shown, the present invention is a kind of automatic forming machine of peach crisp mung bean cake, comprises feeding mechanism and and forming mechanism, and feeding mechanism comprises feeding frame 1, is provided with hopper 2 on feeding frame 1, is provided with fabric compression at the lower end of hopper 2 Cavity 3, feeding compression winches 4 are arranged on both sides of the fabric compression chamber 3, the ends of the feed compression winches 4 outside the fabric compression chamber 3 are provided with gears, the motor meshes with the intermediate gear through the driving gear, and drives the intermediate gear Rotate, and then drive the gear at the end of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com