Oil source system of vibration test device suitable for vacuum environment

A technology of vibration test and vacuum environment, which is applied in the field of hydraulic control, can solve problems such as unbalanced oil supply and oil return, pumping back, difficulty in continuous and stable oil circulation, etc., to improve work efficiency and reliability, The effect of reducing the volume and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

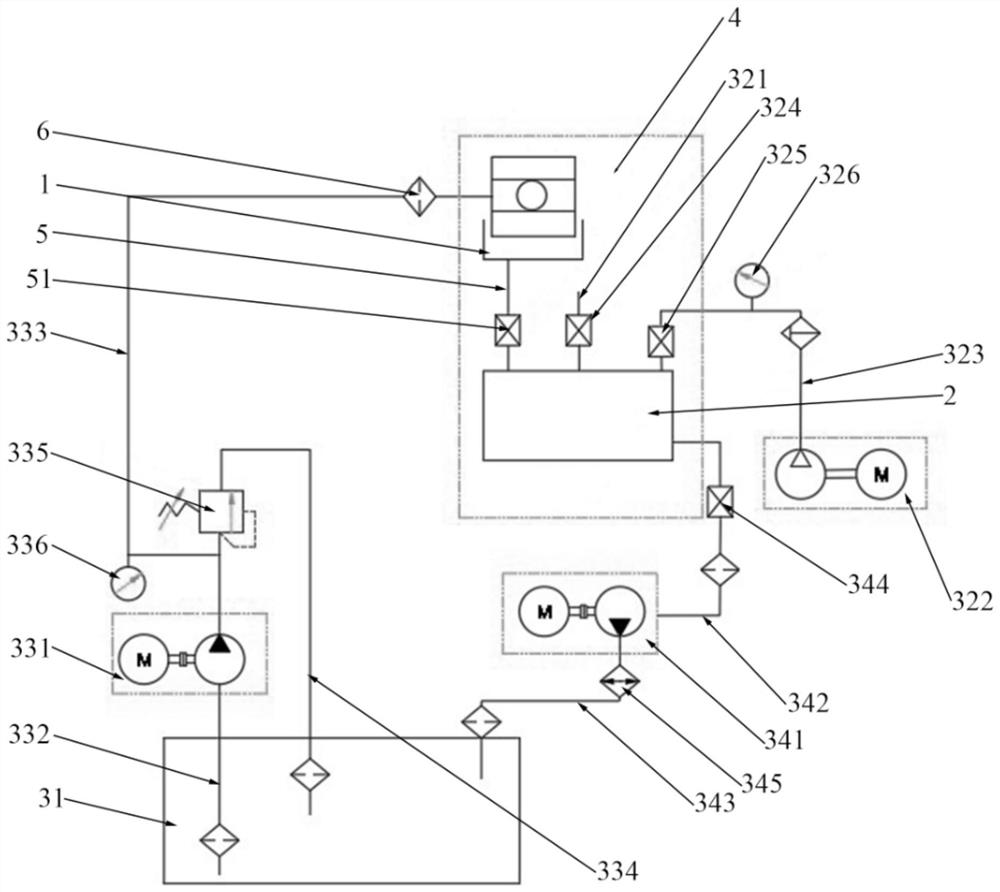

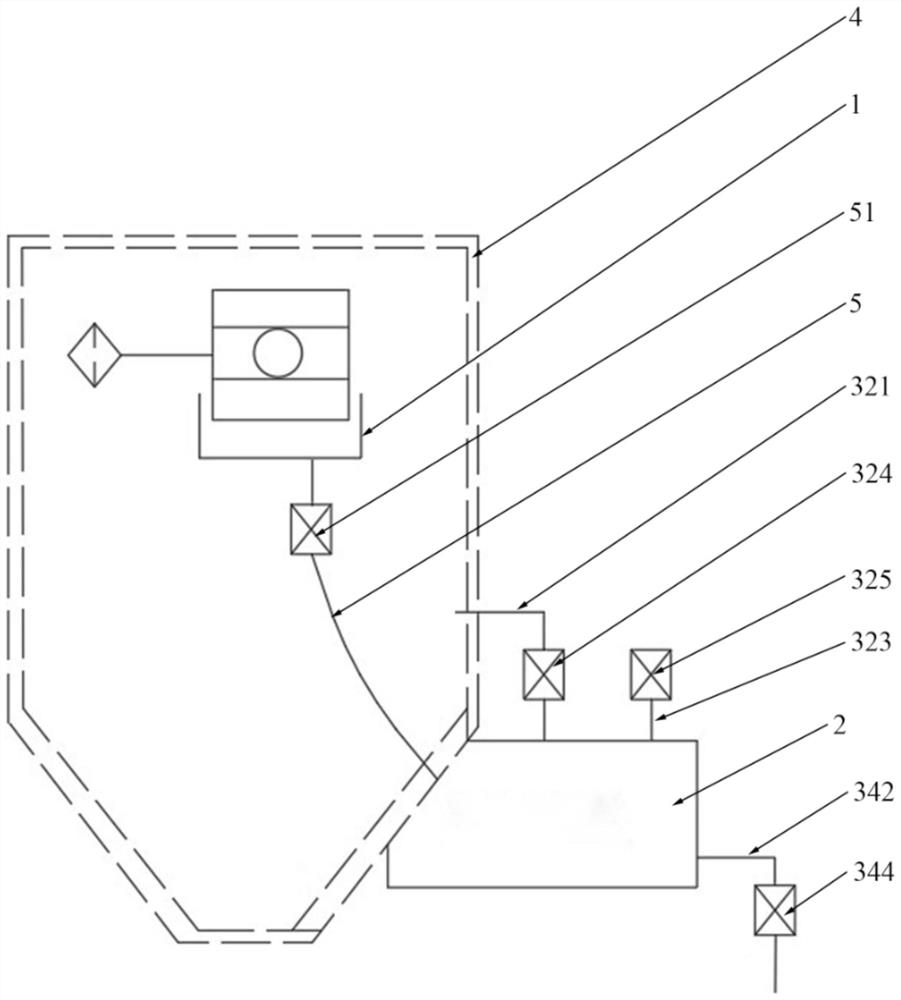

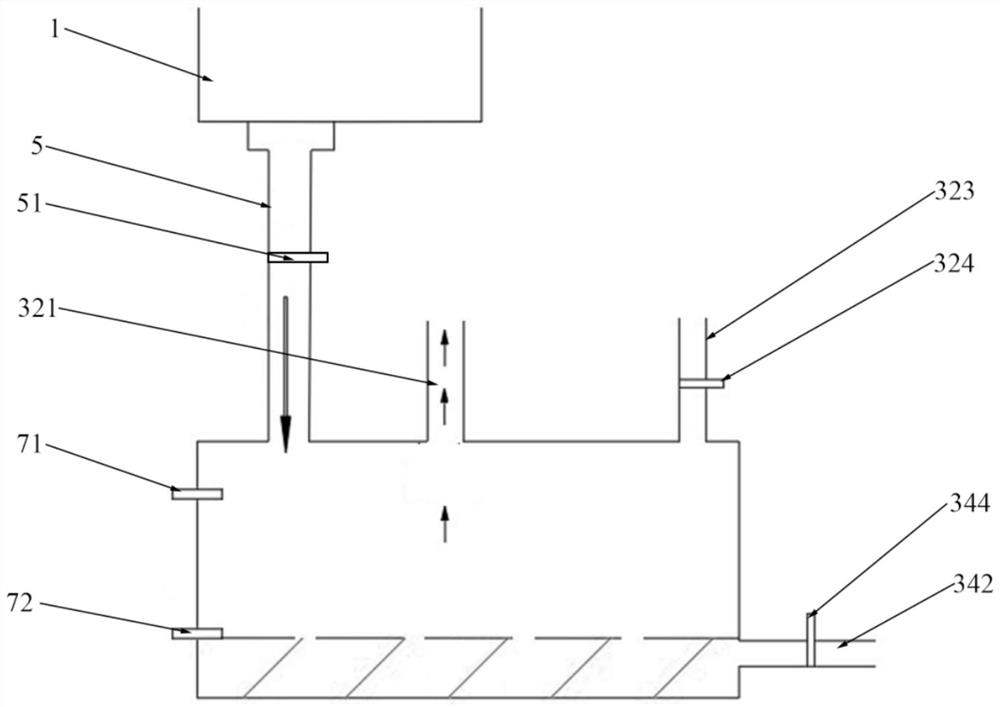

[0047] This embodiment provides an oil source system suitable for a vibration test device in a vacuum environment, such as figure 1 , Figure 3 to Figure 5 As shown, it includes: oil pool part 1, oil storage part 2 and circulation mechanism, oil pool part 1 is set in the sealed cavity of test box 4, the sealed cavity of test box 4 is a vacuum environment, and oil storage part 2 is set in the oil pool Under the part 1, the oil storage part 2 is also arranged in the sealed chamber of the test box 4. The oil pool part 1 has gravitational potential energy relative to the oil storage part 2, and the oil pool part 1 communicates with the oil storage part 2, and the oil pool part 1 The oil can be delivered to the oil storage part 2 under the action of gravity; the circulation mechanism includes an oil tank 31, an air circuit assembly, an oil supply assembly and an oil return assembly. The air circuit assembly is arranged on the oil storage part 2, and the air circuit assembly makes t...

Embodiment 2

[0061] Compared with the oil source system provided in the embodiment 1, the oil source system suitable for the vibration test device provided in this embodiment is that the oil storage part 2 is arranged outside the test box 4, and the air circuit assembly Set on the oil storage part 2, one end of the first air pipe 321 communicates with the sealed chamber of the test box 4, the other end of the first air pipe 321 communicates with the oil storage part 2, one end of the second air pipe 323 communicates with the oil storage part 2, and the second air pipe 323 communicates with the oil storage part 2. The other end of the air pipe 323 communicates with the outside air. As an alternative embodiment, the second connecting pipe 332 can communicate with the air supply part 322. The air supply part 322 is an air pump. One end of the air supply part 322 communicates with the second air pipe 323. The other end of the gas element 322 communicates with a nitrogen source.

[0062] In the...

Embodiment 3

[0064]This embodiment provides an oil source system suitable for a vibration test device in a vacuum environment. Compared with the one provided in Embodiment 1 or Embodiment 2, the difference exists in that the oil pool part 1 directly passes through the oil return assembly. It communicates with the fuel tank 31, and the gas circuit assembly is arranged outside the fuel tank 31.

[0065] The present embodiment provides an oil source system suitable for a vibration test device in a vacuum environment, which reduces the use of oil storage parts 2, correspondingly reduces costs, and saves materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com