Digital Variable Hydraulic Motor Radial Piston Pump

A hydraulic motor, digital variable technology, applied in the direction of variable capacity pump components, liquid variable capacity machinery, liquid fuel engines, etc. problems, to achieve the effect of large adjustable range of displacement, small energy loss, and avoidance of energy transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

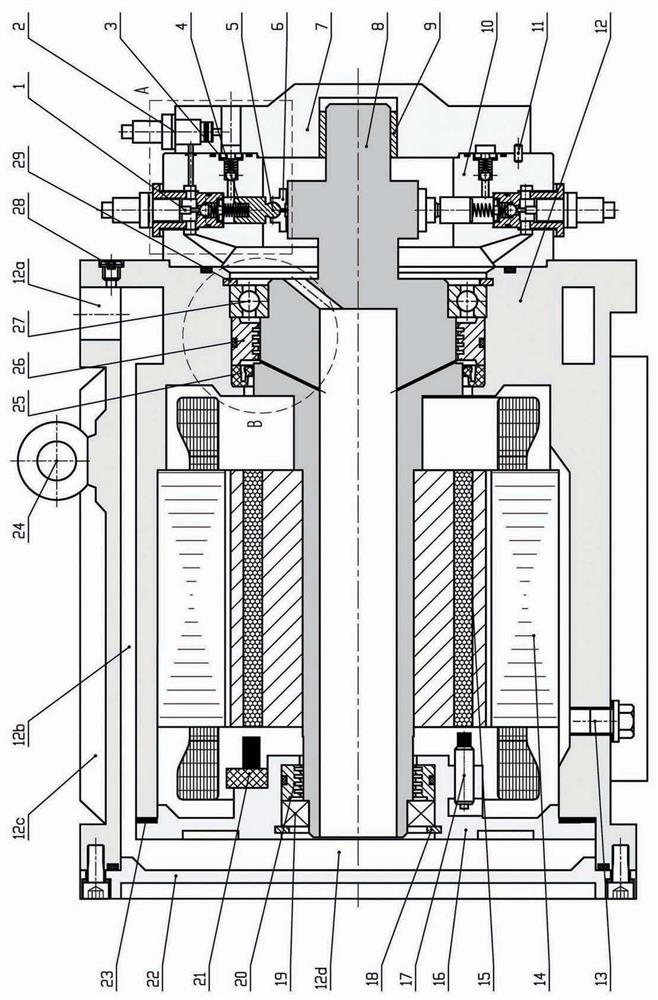

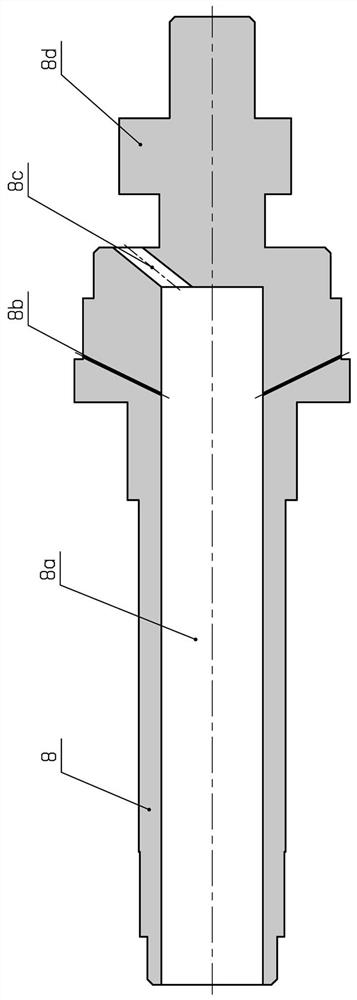

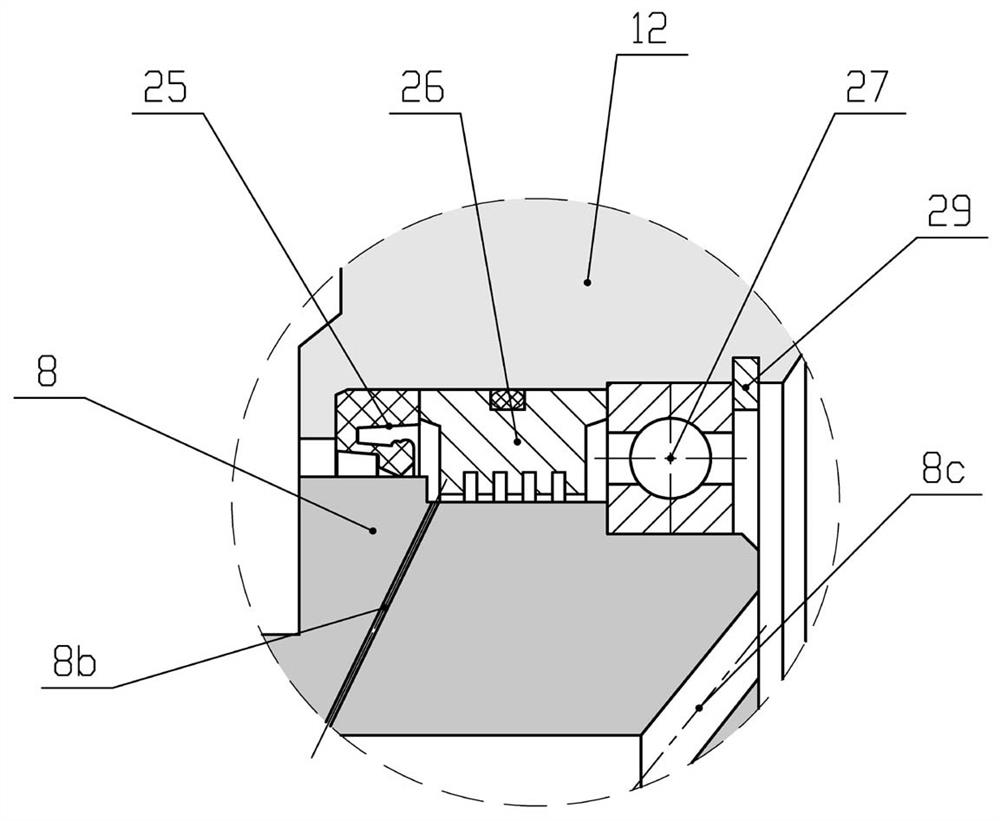

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] Such as Figure 1~Figure 7 As shown, the present invention is a digital variable hydraulic motor radial piston pump, which integrates a permanent magnet motor, a radial piston pump, a liquid-filled centrifugal pump, a digital switch valve and a safety valve, including a digital switch Oil suction check valve 1, safety valve 2, oil discharge check valve 3, return spring 4, ball plunger 5, sliding shoe 6, front end cover 7, hollow composite shaft 8, sliding bearing 9, pump body 10, positioning pin 11. Housing 12, oil drain plug 13, motor stator 14, motor rotor 15, inner end cover 16, speed sensor 17, first spring retaining ring 18, first bearing 19, first sealing ring 20, position sensor 21 , Rear end cover 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com