Electrically-driven gear transmission plunger pump

A gear transmission and plunger pump technology, applied in the field of plunger pumps, can solve the problems of long development and selection cycle, high process requirements, and many interconnected links, shortening the selection and product development process, and expanding the scope of application. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings.

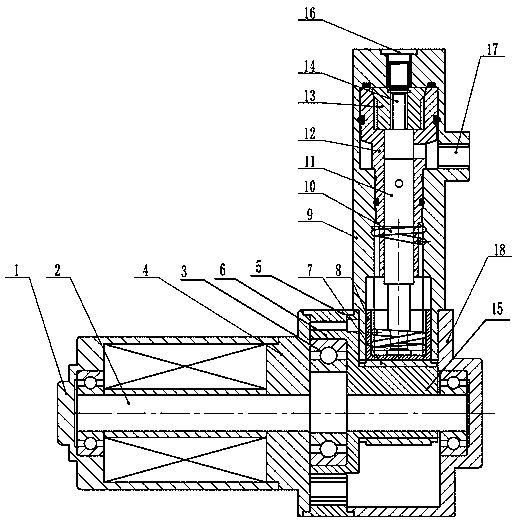

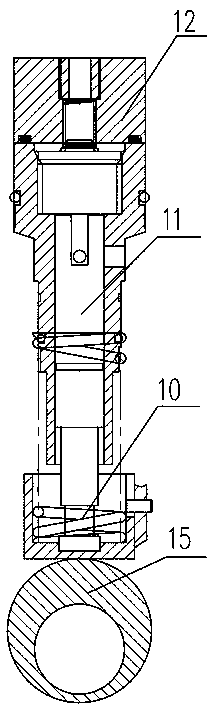

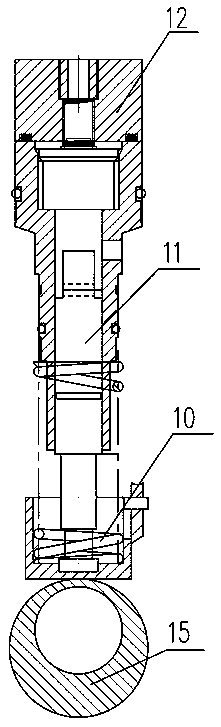

[0030] For specific implementation: see Figure 1 to Figure 4 , An electrically driven gear transmission plunger pump, comprising a motor 1, a reduction transmission mechanism with a small tooth difference and a plunger pump body. The input end of the reduction transmission mechanism with a small tooth difference is connected to the output shaft 2 of the motor 1, and The output end of the tooth difference reduction transmission mechanism rotates eccentrically and is connected with the plunger pump core 11 in the plunger pump body to drive the plunger pump core 11 to move up and down linearly in the plunger pump body.

[0031] In this way, the motor, the reduction mechanism and the plunger pump body are combined to complete the integration of electromechanical and hydraulic integration, complementary advantages and disadvantages, ingenious combination of structures, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com