Star-shaped hydraulic pump

A technology of hydraulic pump and pump body, applied in the field of hydraulic system, can solve the problems of low volume efficiency of gear pump, low working pressure, large flow pulsation, etc., and achieve the effect of improving heat dissipation effect, balanced force and stable total pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

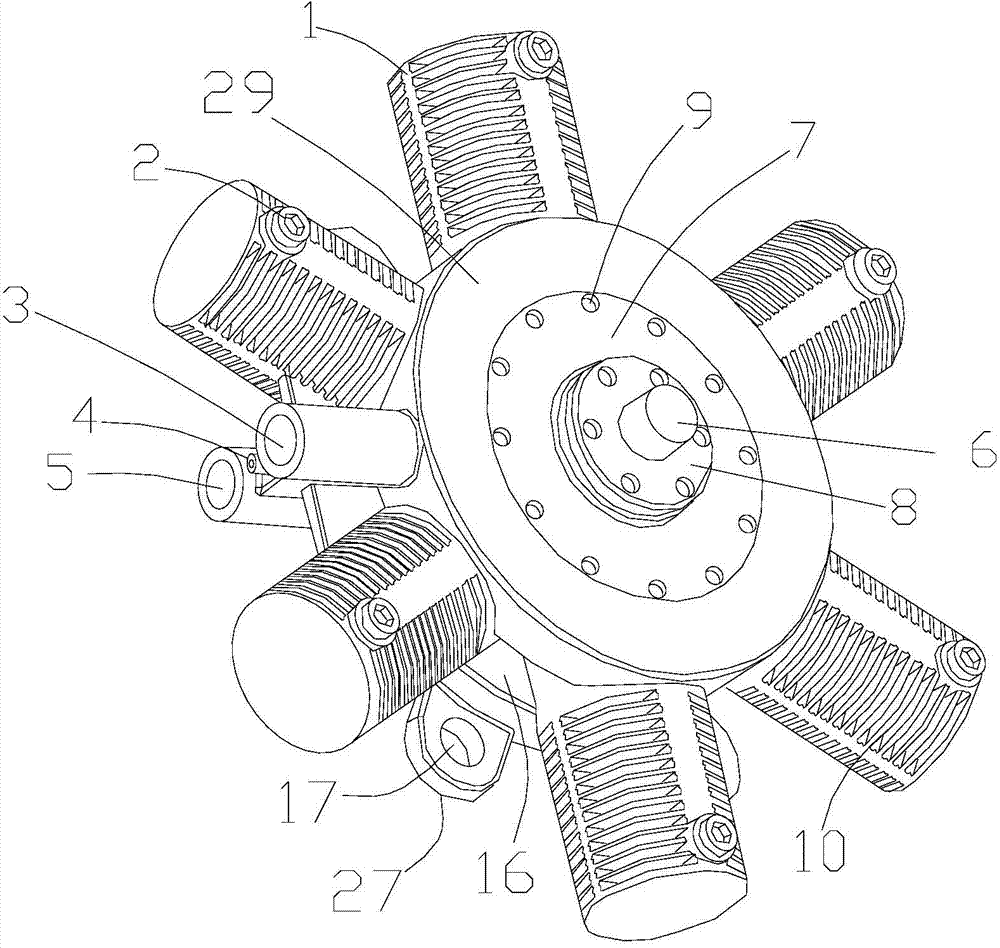

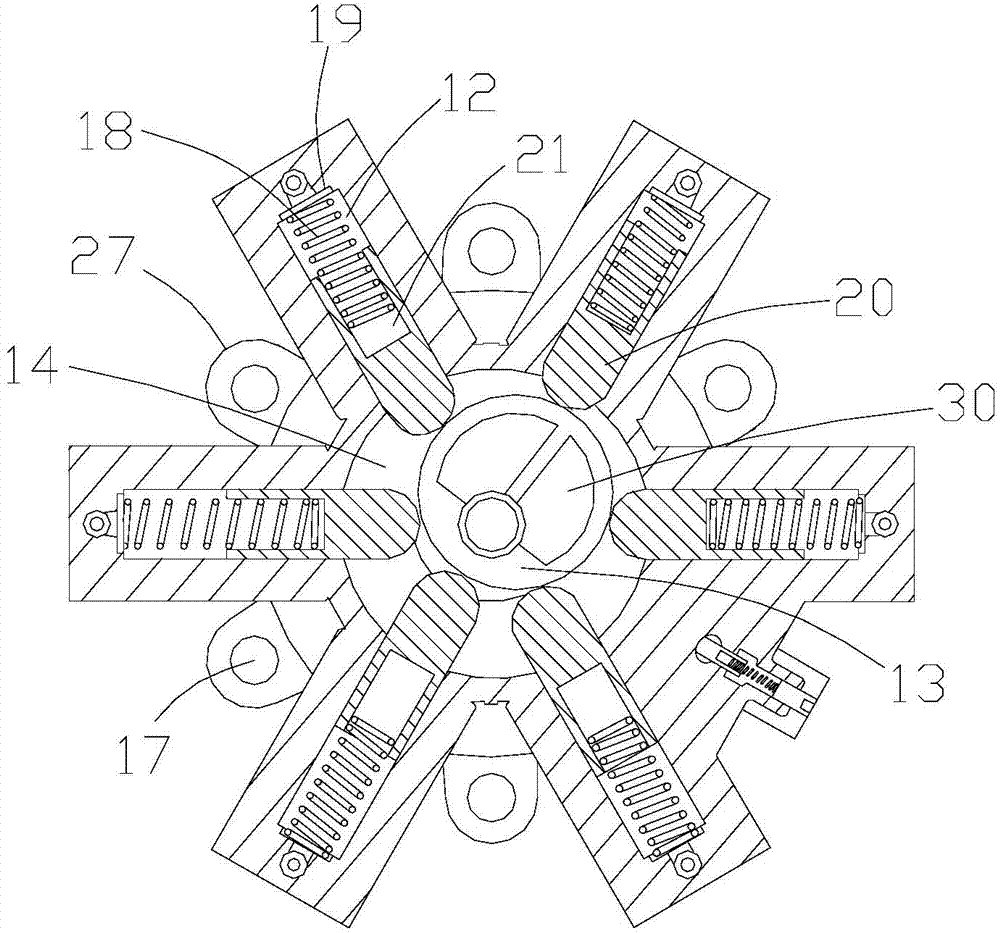

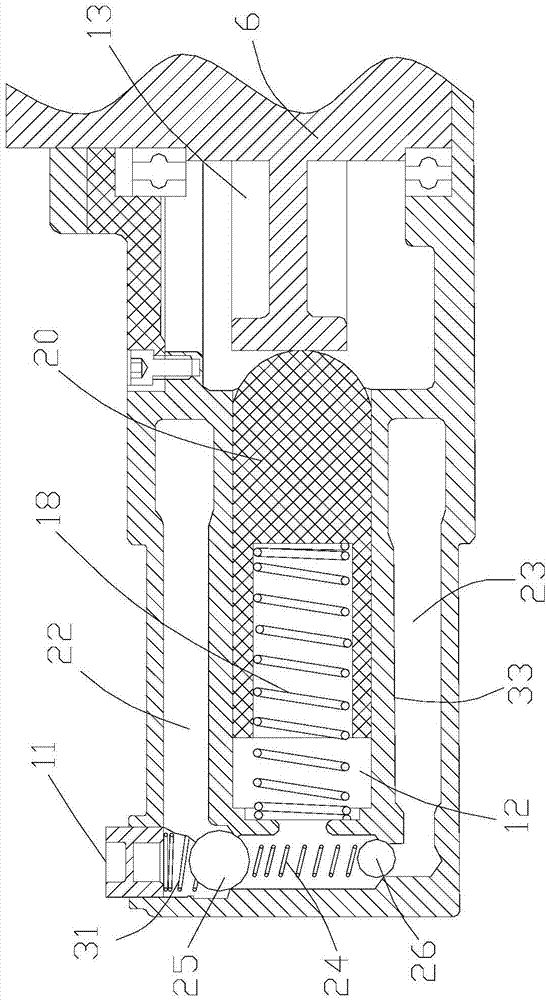

[0024] Such as Figure 1 to Figure 4As shown, it is a star hydraulic pump of the present invention, the hydraulic pump includes a pump body 29 and at least six cylinders 1, the cylinders 1 are evenly distributed around the pump body 29, and the top surface of the pump body 29 is provided with end Cover 7, the end cover 7 is provided with a limit chuck 8, the limit chuck 8 and the end cover 7 are all provided with fixing holes 9, and the screws pass through the fixing holes 9 to realize the limit chuck 8 and the end cover 7, end The fixed connection between the cover 7 and the pump body 29, the interior of the pump body 29 is provided with an inner cavity 14, and the inner cavity 14 is provided with an eccentric wheel 13, so that when the hydraulic pump is working, the six cylinders 1 can ensure the total flow Stable, and make the plunger 20 avoid oil pressure shock when changing from oil suction to oil discharge state. The eccentric wheel 13 is provided with a fan-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com