Diesel engine single pump with high oil suction capacity

A diesel engine and unit pump technology, which is applied in mechanical equipment, engine components, fuel injection pumps, etc., can solve problems such as unstable fuel injection, short valve stem movement distance, and high noise, so as to avoid unstable fuel injection and reduce product quality. Cost, effect of high oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

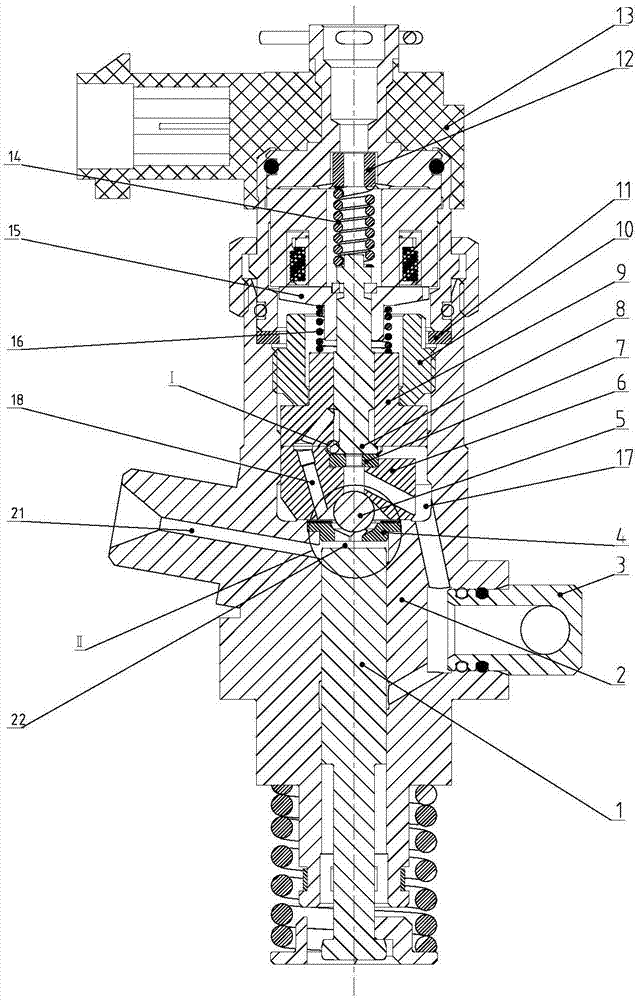

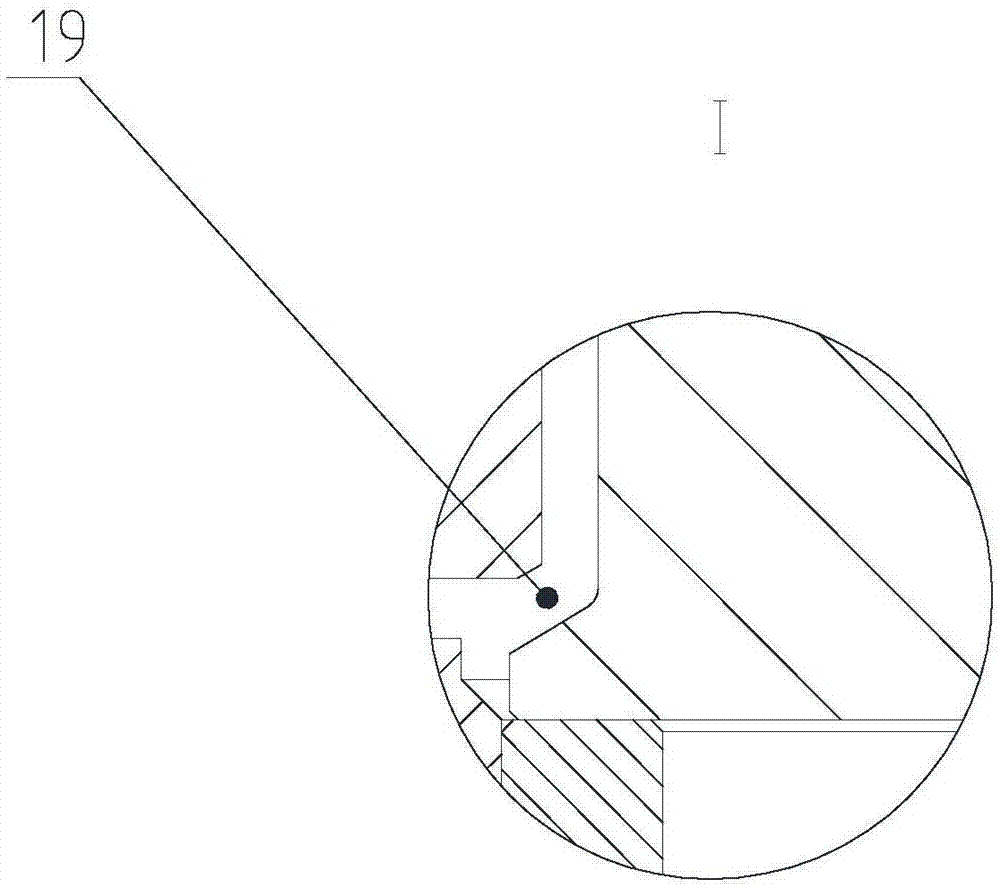

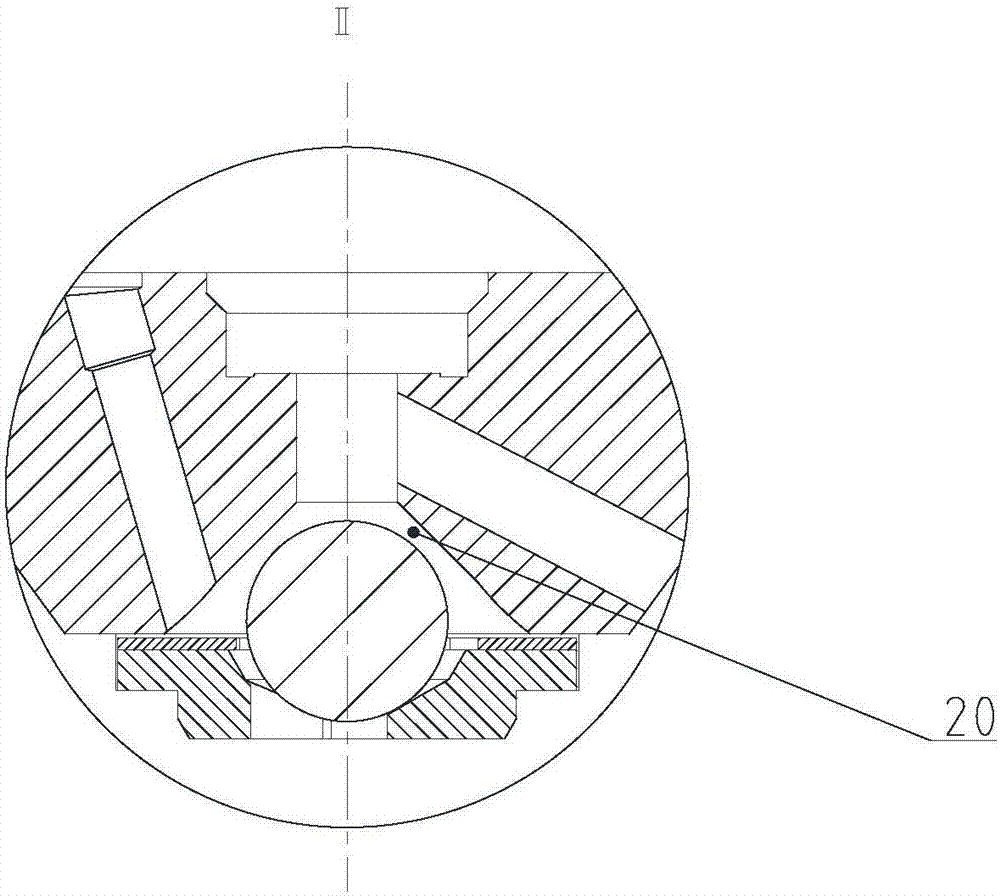

[0011] refer to figure 1 , figure 2 , image 3 . In the embodiment described below, a high oil-absorbing diesel engine unit pump has an electronically controlled unit pump body 2 and assembly of an electromagnet 13 that is powered under the control of the diesel engine ECU to attract the armature 15 to move upward. On the upper valve seat 9 on the pump body 2 , the valve stem 8 assembled in the upper valve seat 9 and the sealing ball 5 seated between the limit ball seat 4 and the lower valve seat 6 . The cylindrical surface of the valve stem 8 has the same diameter as the central hole of the upper valve seat 9 to form a sealing surface; the conical surface of the shaft end of the necking section of the valve stem 8 goes up and fits with the inner conical surface of the lower port of the upper valve seat 9 to form a sealing surface, and goes down to form a sealing surface. Stem necking oil channel 19; the lower valve seat 6 located below the conical surface of the shaft end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com