Self-deoiling adhesive and production process thereof

A production process and technology of adhesives, applied in the directions of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of troublesome use, unable to meet maintenance requirements, affecting the function of adhesives, etc., to improve oil absorption performance, save The effect of cleaning oil stains and improving the effect of oil guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

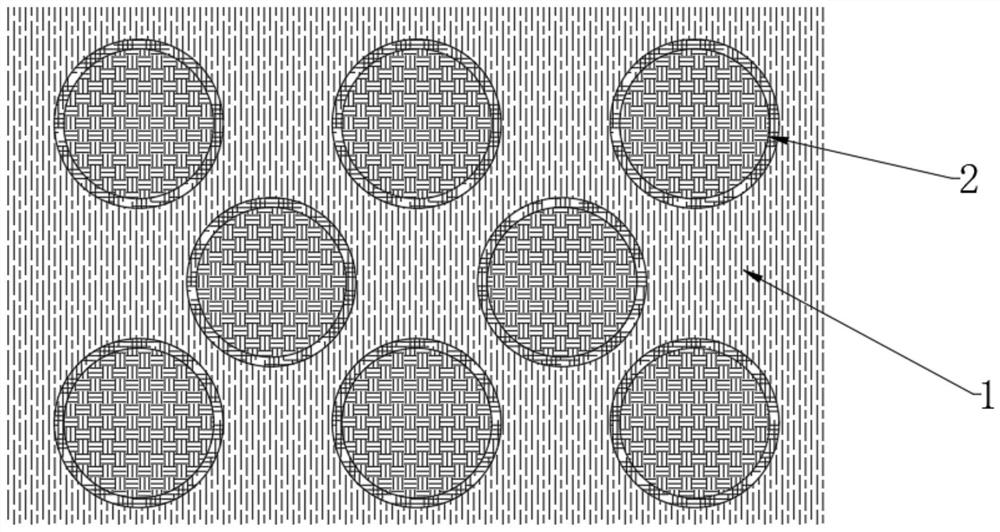

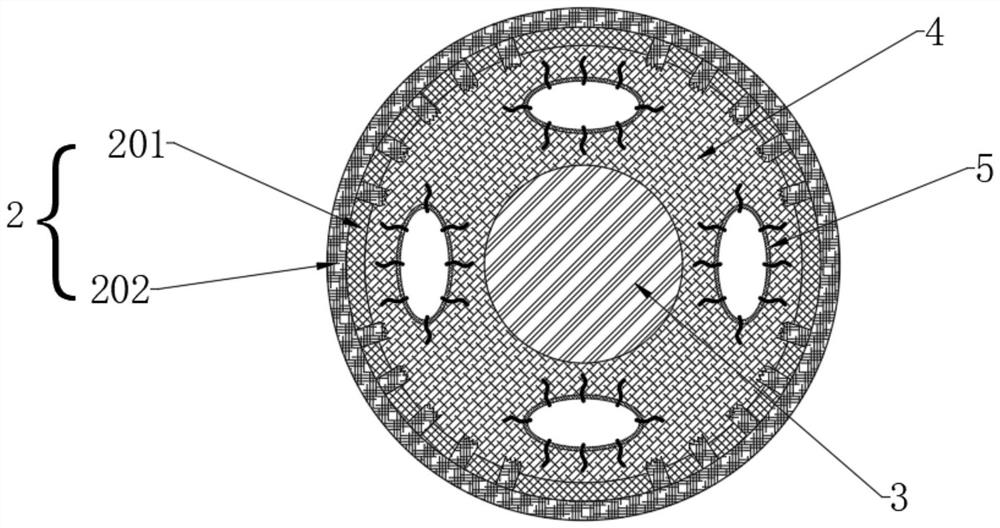

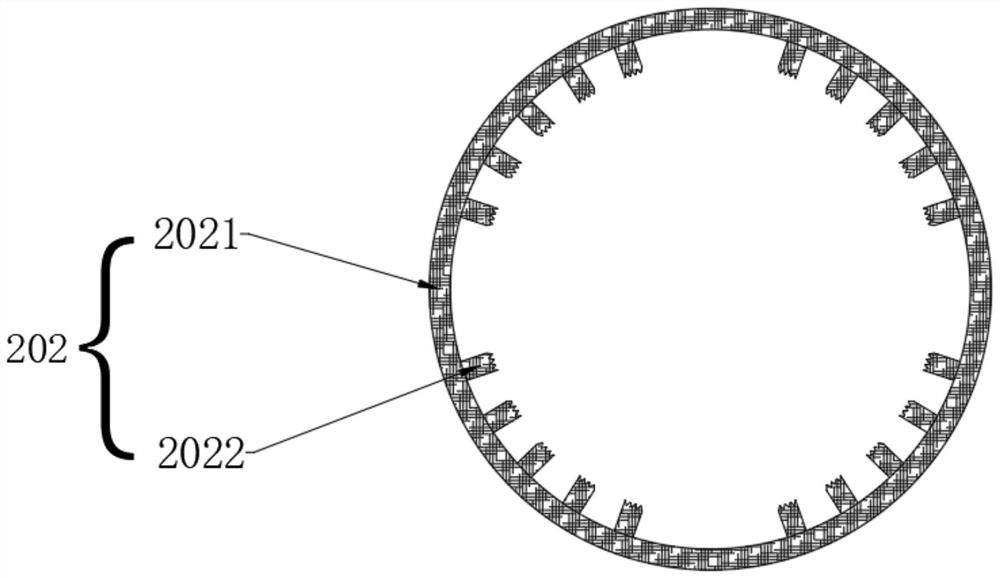

[0048] see Figure 1-6 , a self-removing oil adhesive and its production process, including the adhesive body 1, please refer to Figure 1-3 , the adhesive body 1 is mixed with a plurality of randomly distributed degreasing balls 2, and the mixing ratio of the adhesive body 1 and the degreasing balls 2 is 3:1, which is to ensure that the degreasing balls 2 can effectively remove oil while not Affects the bonding effect of the adhesive body 1. The degreasing ball 2 includes an inner shell 201 and an adsorption shell 202. The inner shell 201 is for absorbing oil, and the inner shell 201 is a hollow spherical shell to allow as much oil as possible to enter the interior. Absorbed by the oil-absorbing filler 4, the adsorption shell 202 includes a spherical adsorption body 2021. The inner wall of the adsorption body 2021 is fixedly connected with a plurality of evenly distributed guides 2022, and the guides 2022 penetrate into the inner shell 201. When the adsorption body 2021 absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com