Low-speed axial plunger hydraulic pump

A technology of hydraulic pump and plunger, applied in the field of axial plunger hydraulic pump, can solve the problems of small transmission resistance and friction loss, pulsation of output flow, poor self-priming characteristics, etc., to reduce friction, reduce radial friction and absorb oil. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

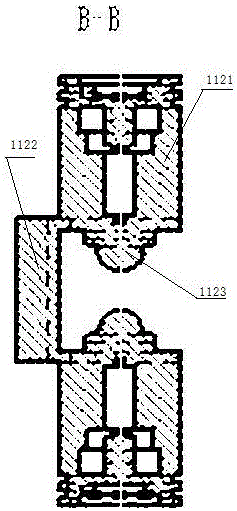

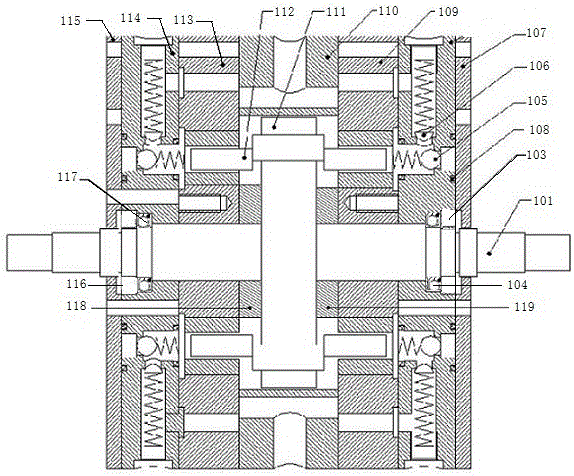

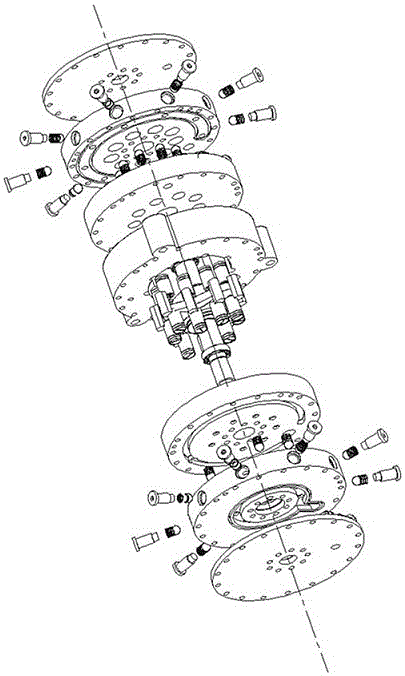

[0060] Such as figure 1 , figure 2 The low-speed axial plunger hydraulic pump shown is mainly composed of a cam drive shaft 101, a cam box 110, left and right plunger cylinders 113 and 112, a two-way conjoined plunger 111, left and right oil distribution plates 114 and 108, and left and right side covers 115 and 107;

[0061] Cam transmission shaft is made up of the integral structure and one-way bearing that drive shaft 101 and double-sided space cam 111 form one-way transmission mechanism, and double-sided space cam 111 has two left-hand helical surfaces and two right-hand helical surfaces (i.e. lift, drop stroke, lift, and drop four-section curved surface), when the cam drive shaft rotates one revolution, the two-way conjoined plunger 112 realizes two working cycles in the plunger cylinder of the plunger cylinder body 113.

[0062] The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com