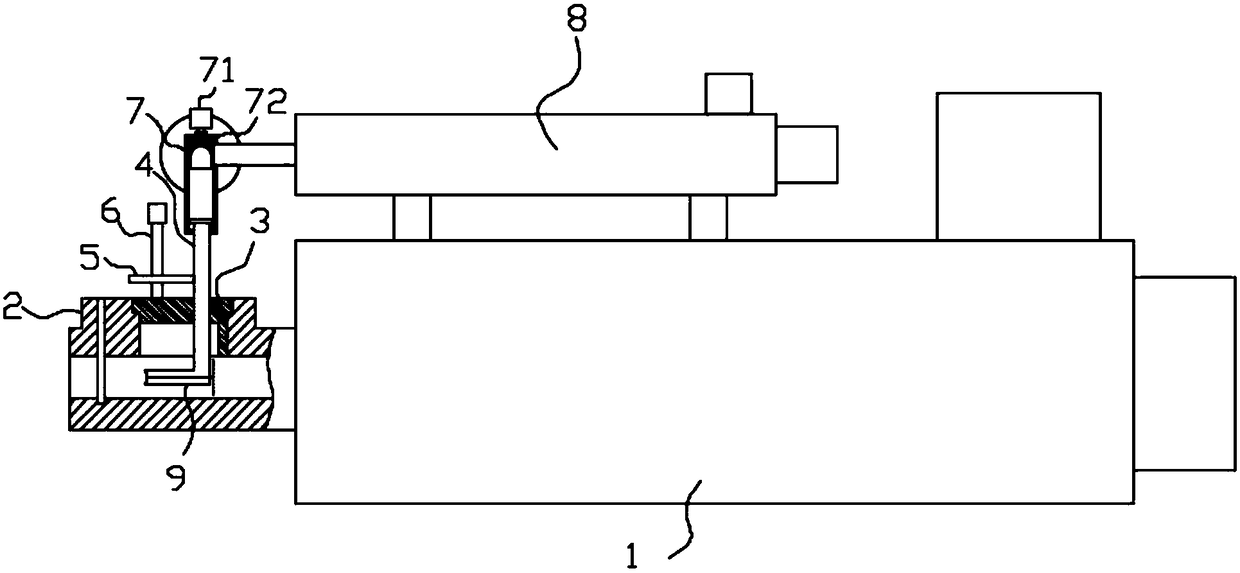

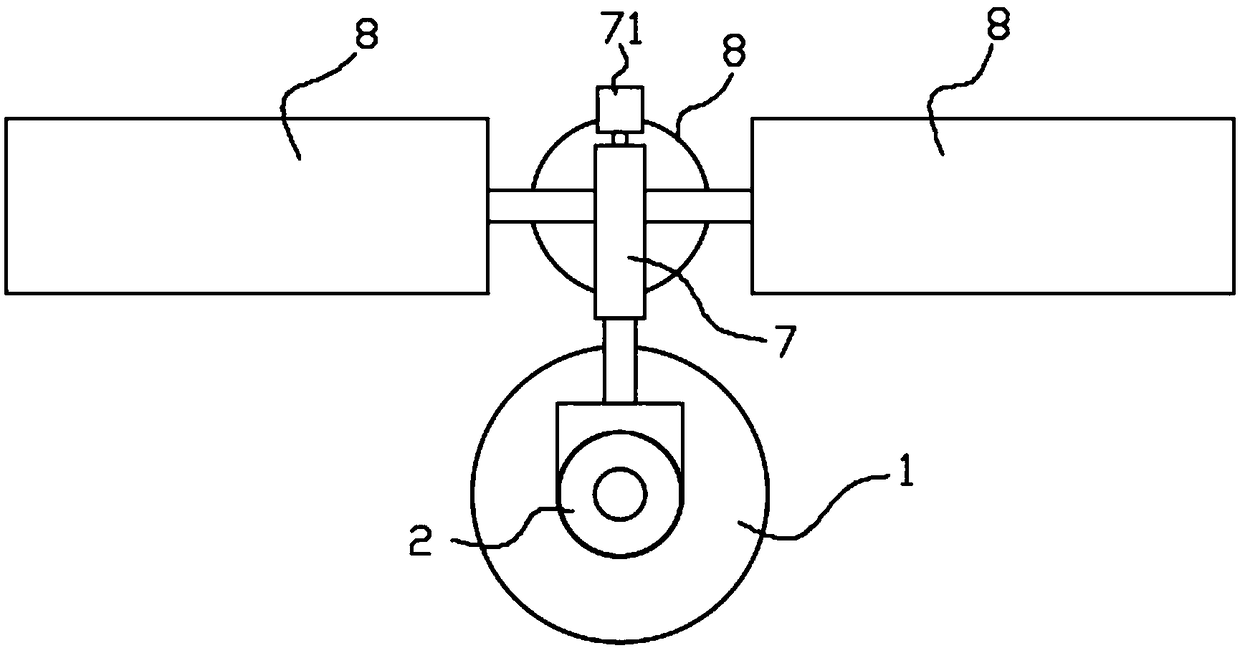

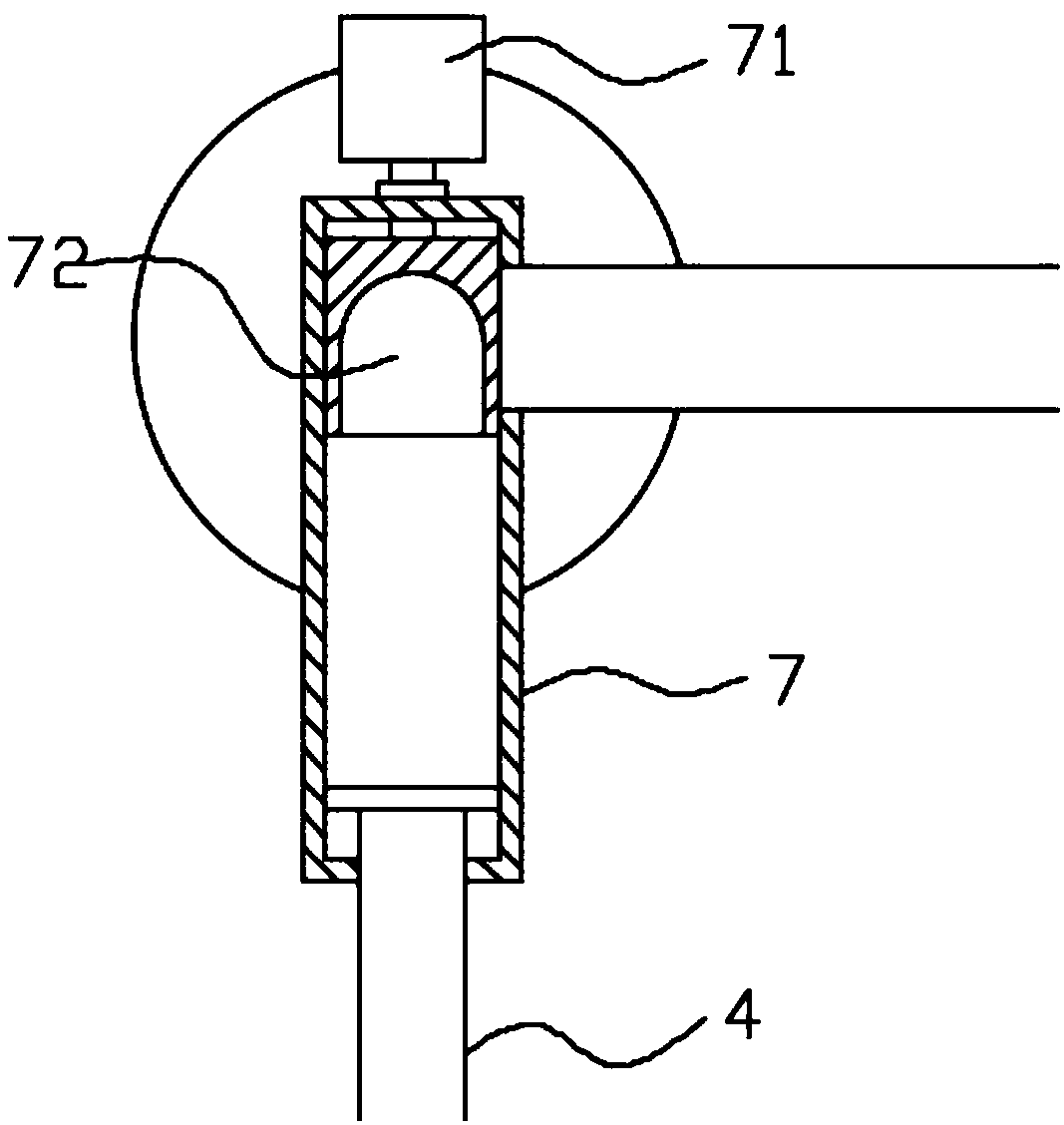

Core-casting gluten processing device capable of fast adjusting cores and process for processing gluten

A processing device and gluten technology, which are applied in the field of gluten processing, can solve the problems of taste solidification, gluten food losing interest in eating, etc., and achieve the effects of good chewiness, improvement of starch aging and rejuvenation, and improved taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A process for processing gluten with a core-injecting gluten fast core-adjustable processing device, which includes the following processing steps:

[0045] 1) Prepare a mixed aqueous solution: by weight percentage, distill 40% glyceryl monostearate, 25% mono- and di-fatty acid glycerides, 9% mono- and diglycerides of diacetyl tartaric acid, 9% sodium stearoyl lactylate, 6% of guar gum and 1% of xanthan gum are mixed to obtain a compound improver, and 0.23 parts of compound improver and 0.2 part of honey are added to 7.4 parts of warm water according to the ratio of parts by weight, and the water temperature is 65 ° C. Stir to disperse evenly, then add 1.2 parts of table salt, stir to make it evenly mixed, and make a mixed aqueous solution;

[0046] 2) Mixing of raw material powder: Add 24 parts of wheat flour into the mixer, cover the sealing cover of the mixer, start the stirring switch for 5 seconds, make the powder compact, and prevent water from seeping out from th...

Embodiment 2

[0053] A process for processing gluten with a core-injecting gluten fast core-adjustable processing device, which includes the following processing steps:

[0054] 1) Prepare a mixed aqueous solution: by weight percentage, distill 50% glyceryl monostearate, 30% mono- and di-fatty acid glycerides, 10% diacetyl tartaric acid mono- and diglycerides, 10% sodium stearoyl lactylate, 8% of guar gum and 2% of xanthan gum are mixed to obtain a compound improver, and 0.25 parts of compound improver and 0.4 part of honey are added to 7.6 parts of warm water according to the ratio of parts by weight, and the water temperature is 75 ° C. Stir to disperse evenly, then add 1.6 parts of table salt, stir to make it evenly mixed, and make a mixed aqueous solution;

[0055] 2) Mixing of raw material powder: Add 28 parts of wheat flour into the mixer, cover the sealing cover of the mixer, start the stirring switch for 5 seconds, make the powder compact, and prevent water from seeping out from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com