Oil distributing tray with pressure equilibrium chamber

A technology of oil distribution plate and balance cavity, which is applied in the field of automobile power steering mechanism manufacturing. It can solve the problems of large steering noise, affecting driving comfort, and large pressure pulsation of oil pump output oil, so as to reduce pulsation and fully absorb oil. , Prevent the effect of air suction and insufficient oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

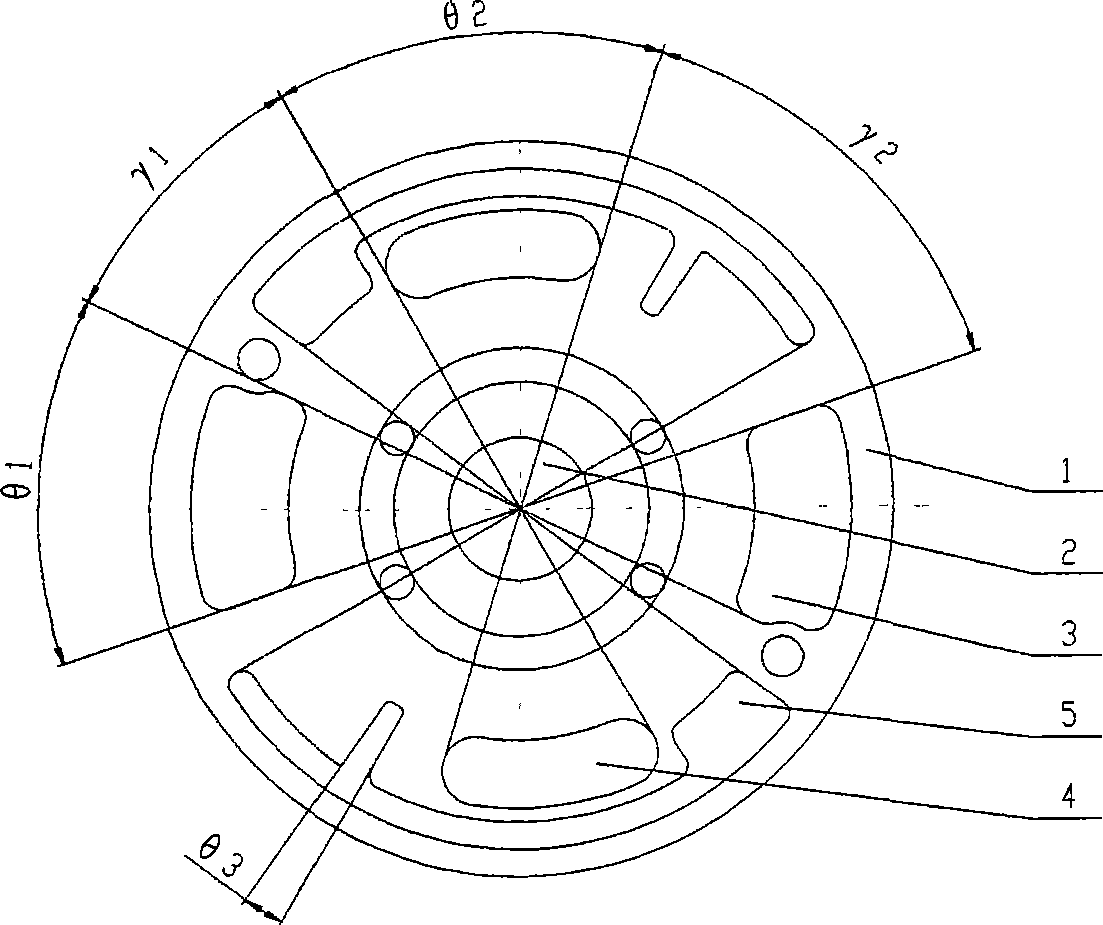

[0009] As shown in the figure, the present invention is mainly composed of an oil distribution plate body 1 and a central hole 2 . The oil distribution plate body 1 is provided with two oil suction windows 3 and two oil pressure windows 4 symmetrical to the central hole 2 , and two pressure balance chambers 5 symmetrical to the central hole 2 .

[0010] The pressure balance chamber 5 makes the oil in the sealed volume transition from the oil suction chamber to the oil pressure chamber when the oil pump is working, and first passes through the pressure balance chamber 5, so that the pressure of the oil in the chamber rises close to the pressure of the oil pressure chamber, and then with the pressure The oil chambers are connected to reduce the output oil pulsation.

[0011] The oil distribution plate body 1 is provided with an oil suction window angle θ symmetrical to the central hole 2 1 and oil pressure window angle θ 2 and pressure balance chamber angle θ 3 The proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com