Automobile spring collision bead assembly service life testing machine with coating and eccentric wheel mechanism

A technology for automotive spring and life testing, which is applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc. It can solve the problems of accelerating the optimization cycle of automotive spring bumper components, increasing capital, etc., and improving testing efficiency. , improve the service life, and facilitate the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

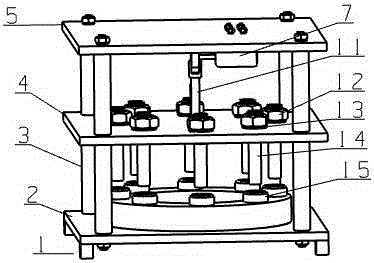

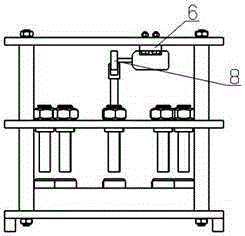

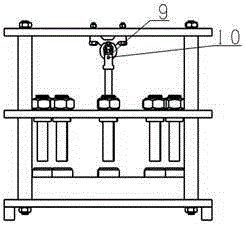

[0015] Such as Figure 1 to Figure 5 As shown, a coating eccentric wheel mechanism automobile spring component life testing machine, including the bottom plate pad 1, fixed bottom plate 2, guide post 3, middle fixed plate 4, upper fixed plate 5, motor fixing seat 6, stepless speed regulation Motor 7, eccentric wheel 8, rolling bearing 9, mandrel 10, pull rod 11, lock nut 12, washer 13, pressure measuring head 14, spring bead holder 15.

[0016] Base plate pads 1 are installed on the four corners of the fixed base plate 2 to play the role of fixed support. The guide post 3 with steps is installed on the fixed base plate and locked by nuts. The fixed base plate 2 is equipped with a spring bumper. Beads and evenly distributed cage 15.

[0017] The upper fixed plate 5 is also connected with the guide column 3 with st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com