Magnetic detection method of stress concentration region and microcrack on surface of magnetic metal component

A surface stress and magnetic metal technology, applied in the direction of material magnetic variables, etc., can solve the problems of missed judgment, difficulty in accurately determining the stress concentration area, leakage magnetic field is easy to dilute the magnetic memory characteristics, etc., and achieve huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

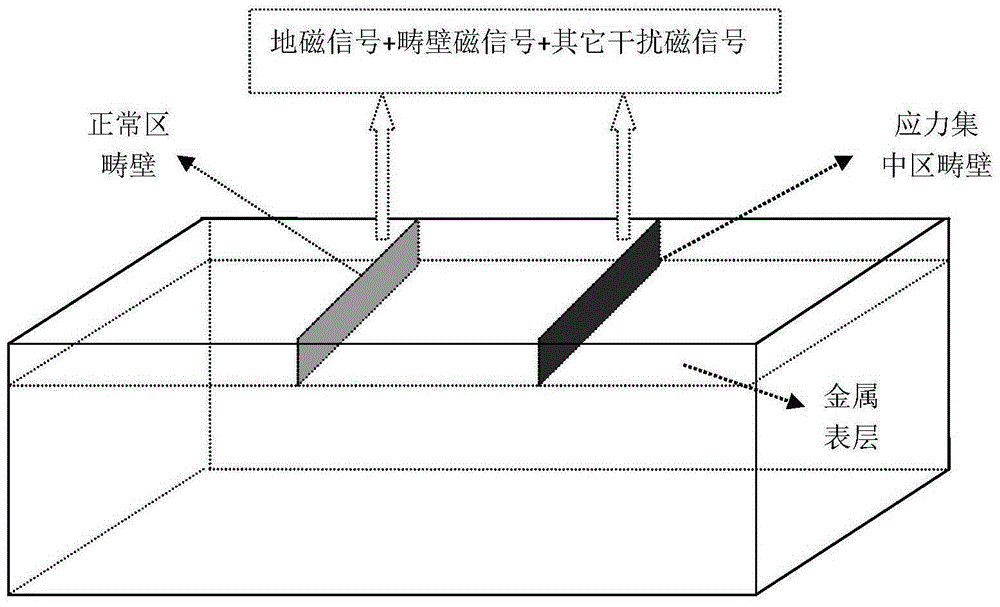

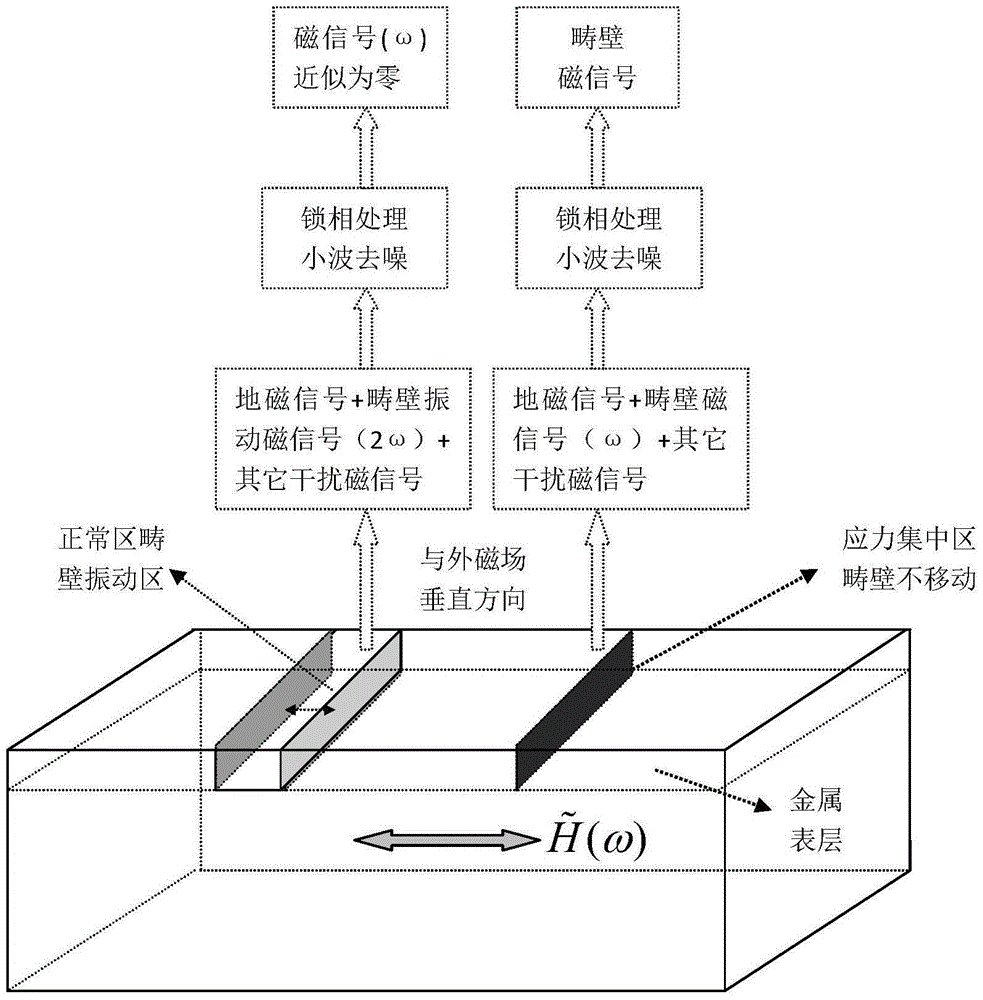

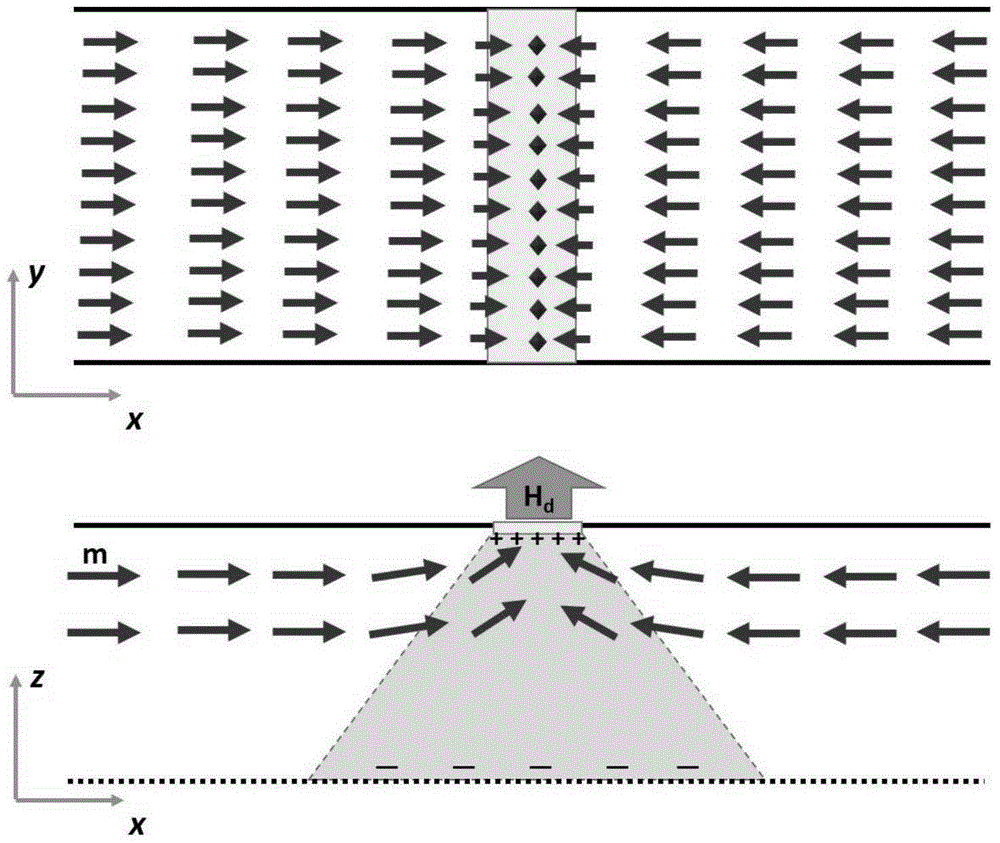

[0062] Specific implementation methods such as Figure 4 As shown, for the magnetic metal components to be detected, apply an alternating magnetic field of a certain strength in the direction of the metal surface, use high-precision magnetic sensors to detect weak magnetic signals near the metal surface, and use phase-locking technology to detect weak magnetic signals. The magnetic signal is processed, and the detected weak magnetic signal is processed by phase-locking technology, and the characteristic signal related to the stress concentration area is extracted according to the characteristics of the surface weak magnetic signal of the stress concentration area, and the corresponding stress concentration area or micro crack is obtained. Finally, the computer drawing is used to obtain the distribution map of the stress concentration area on the metal surface, and the quantitative relationship between the size, strength and shape of the stress concentration area is given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com