Method for measuring monomer conversion rate in additive synthetic process

A technology of monomer conversion rate and synthesis process, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of long measurement time, inability to achieve rapid measurement, etc., and achieve the effect of short detection time, fewer samples, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

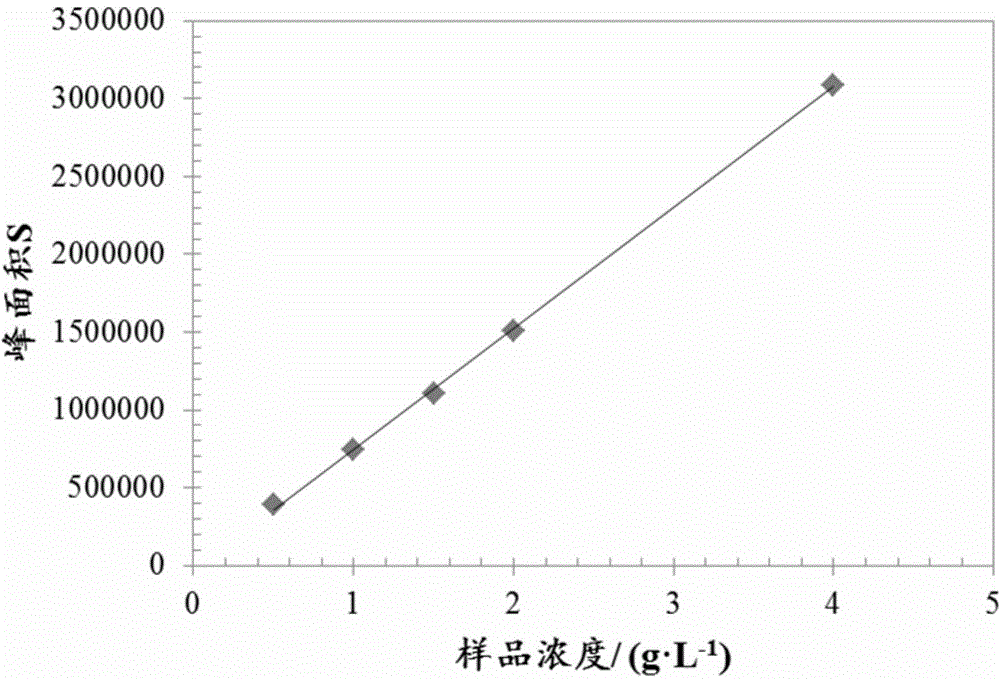

[0034] Embodiment 1: establish the standard concentration of polybutylmethacrylate and the linear function relational expression of peak area

[0035] (1) Establish a linear function relational expression:

[0036] Dissolve 5 g of polybutyl methacrylate (produced by Polymer Standers Service GmbH, with a number-average molecular mass of 105,000) in 200 mL of tetrahydrofuran, transfer the resulting solution to a 500 mL volumetric flask, dilute to volume with tetrahydrofuran, shake well, and prepare a polymer Butyl methacrylate mass concentration is the standard solution of 10g / L. Then this solution is diluted to the polybutylmethacrylate standard solution of 0.5g / L, 1.0g / L, 1.5g / L, 2.0g / L and 4.0g / L respectively, and carries out gel permeation chromatography analysis respectively, A unique peak appears on the gel chromatogram, and the time interval from appearance to disappearance of the peak is 15.90-16.10 min, and the peak area integrated by the chromatographic workstation is...

Embodiment 2

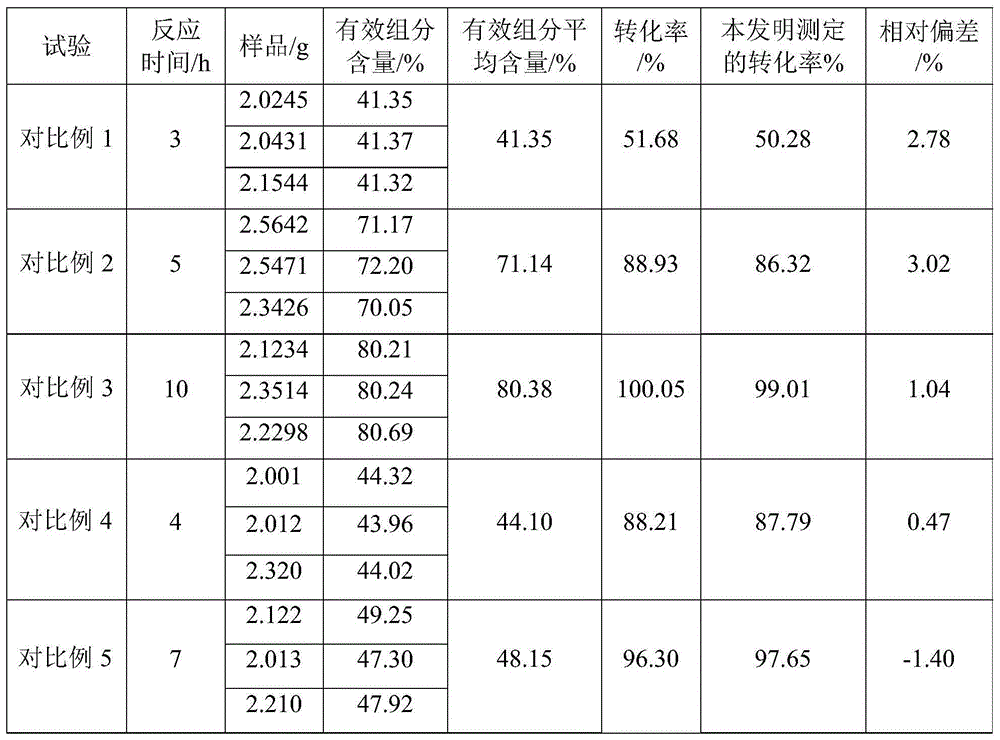

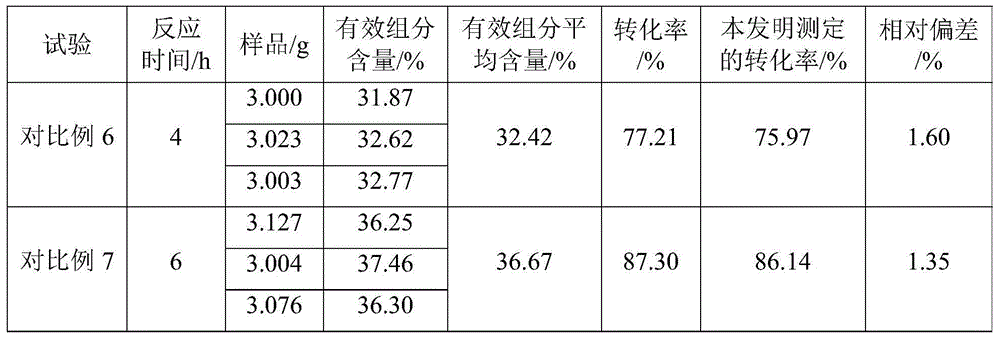

[0041] Example 2: Determination of monomer conversion rate when polymethacrylate type pour point depressant A is synthesized for 3 hours

[0042] Under the protection of nitrogen, add 20g base oil (purchased from Ssangyong Company, the brand is 100N, the same below) in the reactor equipped with mechanical stirring, then add 80g methacrylate (decyl methacrylate, methacrylic acid Lauryl ester and stearyl methacrylate are a mixture of 1:1:1 by weight, the same below), an appropriate amount of benzoyl peroxide and dodecyl mercaptan are mixed into the above-mentioned reaction kettle, and then The reaction kettle was heated to 91-103°C, stirred rapidly and the reaction temperature was maintained at 91-103°C. After reacting for 3 hours, weigh 0.6 g of the reaction material and dissolve it in 200 mL of tetrahydrofuran, and transfer the obtained solution to a 500 mL volumetric flask, dilute to volume with tetrahydrofuran, shake well, and prepare a concentration of 1.2 g / L (polymethacry...

Embodiment 3

[0043] Example 3: Measurement of monomer conversion rate when polymethacrylate type pour point depressant A was synthesized for 5 hours

[0044] The synthesis process of polymethacrylate type pour point depressant A is the same as in Example 2.

[0045] After reacting for 5 hours, weigh 0.7 g of the reaction material and dissolve it in 200 mL of tetrahydrofuran, and transfer the resulting solution to a 500 mL volumetric flask, dilute to volume with tetrahydrofuran, shake well, and prepare a concentration of 1.4 g / L (polymethacrylate The theoretical concentration is 1.12g / L) standard solution. Then this solution is carried out gel permeation chromatography analysis under the chromatographic operating condition identical with embodiment 1, two spectral peaks appear on the gel chromatogram, the spectral peak of polymethacrylate is from the time interval of appearance to disappearance For 13.90-18.70min, record the peak area integrated by the chromatographic workstation. The sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com