Simulation test apparatus of tectonic stress field and method thereof

A technology for simulating experiments and tectonic stress, applied in geophysical measurement, instruments, etc., can solve problems such as the inability to realize simultaneous movement of multiple regions, imperfect experimental devices, and immature methods and theories, and achieve the solution of uneven force exerted by solids, Good toughness, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

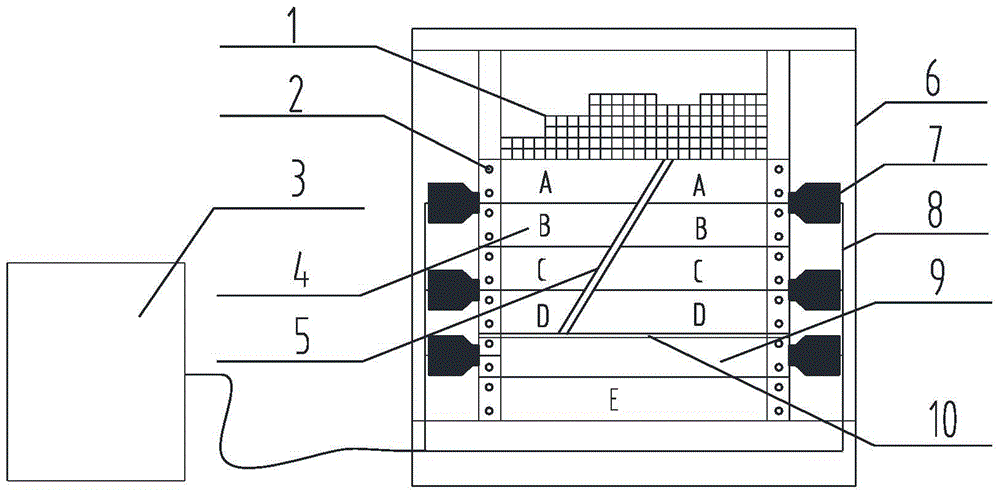

[0057] This embodiment simulates a normal fault, and the normal fault structural stress field simulation test device, on the basis of the above-mentioned device, is selected as two smooth plates located above the water bag, and the two smooth plates are independent, and the two smooth plates are spliced When together, they can completely cover the top surface of the water bladder, in the laying process of similar materials, such as figure 2 As shown, the bottom layer of similar material E is laid first, and after E is laid, a water bag is laid on top of E, the above two smooth boards are laid on top of the water bag, and similar materials D, C, B, and A are laid on top of the smooth board in sequence Layer, the similar material above the smooth plate needs to prefabricate the fault, that is, the partition 5 with a certain inclination angle is set on the D, C, B, A similar material layers to simulate fracture.

[0058] The specific test method is:

[0059] The first step is t...

Embodiment 2

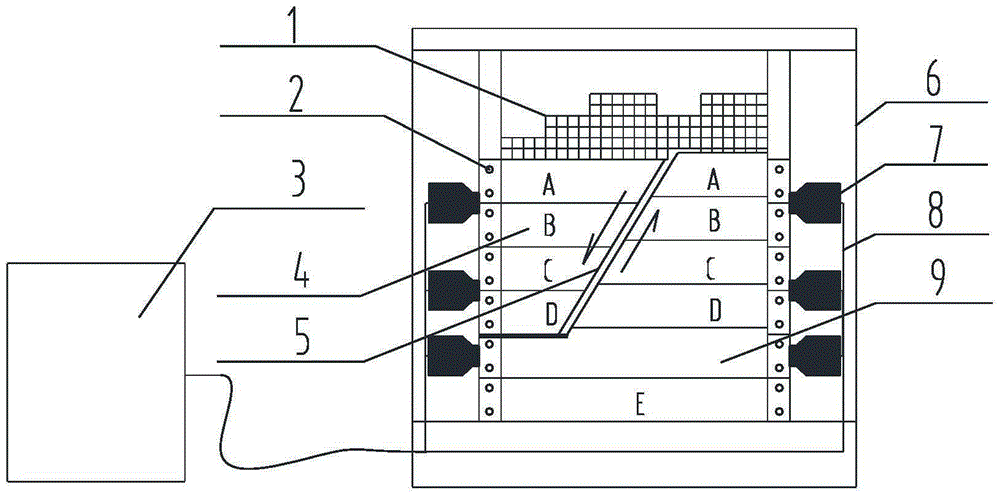

[0069] This embodiment simulates a reverse fault, and the device for simulating a reverse fault is as follows image 3 As shown, it is the same as in Example 1. Firstly, the bottom layer of similar material E is laid. After E is laid, a water bag is laid on top of E, the above two smooth boards are laid on the top of the water bag, and D and C are laid on top of the smooth board in turn. , B, and A are similar material layers, and the two are slightly different in the specific test method. The difference from Example 1 is that in the specific test method, in the fifth step, the present embodiment is to remove the partition and the lower end of the fault. Click the smooth plate on the left part to simulate the formation and evolution process of the reverse fault structure.

Embodiment 3

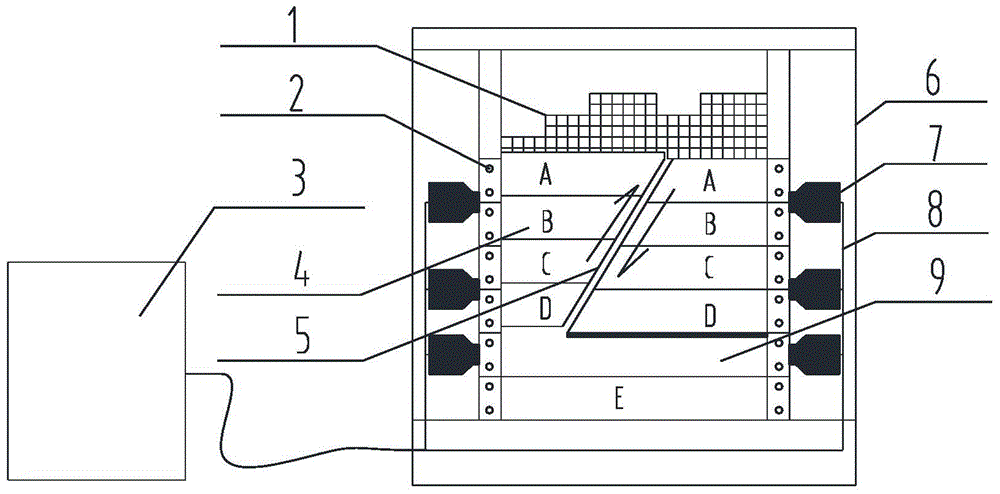

[0071] This embodiment simulates combined faults, such as Figure 4 As shown in the combined fault structural stress field simulation test device, after the loading module 1, the lateral loading system 7 and the control console 3 are all installed in place, the bottom layer E is laid first in the cuboid frame 6, and after E is laid, the bottom layer E A water bag is laid above the water bag, and three smooth boards are laid above the water bag. The lengths of the three smooth boards and the positions of their splices are divided according to the lower endpoint of the fault plane of the combined fault. The similar material layer above the smooth board In D, C, B, and A, there are prefabricated partitions to simulate faults. There are two partitions, and the inclination angles of the two partitions are obtained through calculation.

[0072] The specific simulation method for simulating combined faults in this embodiment includes the following steps:

[0073] The first step is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com