A rubber extruding compound head locking mechanism

A technology of extrusion compounding and locking mechanism, which is applied in the field of rubber processing machinery and equipment, can solve the problems of bending deformation of the locking block, complex structure and difficult adjustment, and achieve the effects of simplified structure, long service life and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

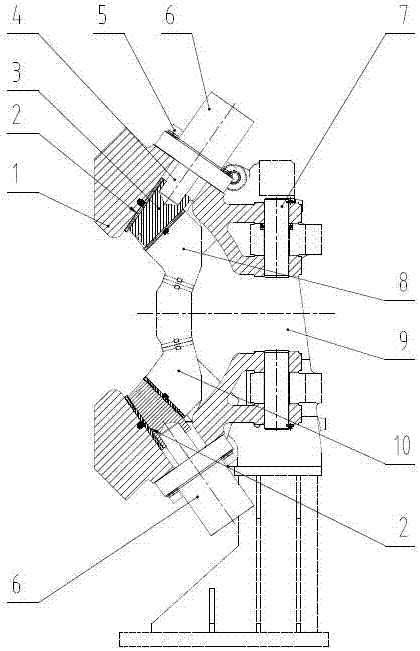

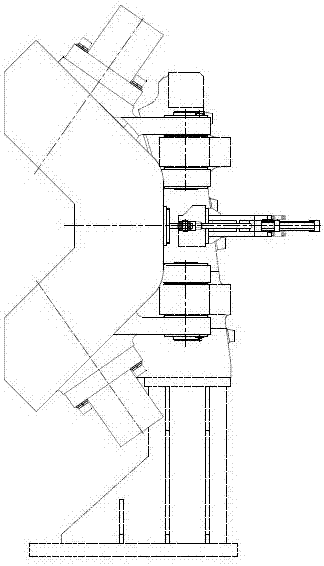

[0021] Such as figure 1 , 2 , 3, the present invention provides a rubber extrusion compound head locking mechanism, including a head base 9 and a top head 8 and a bottom head 10 hingedly connected to the top and bottom of the head base 9 , the upper and lower parts of the left and right sides of the machine head seat body 9 are respectively hinged to the lock doors 1 on the left and right sides through column pins 7, and the opening and closing hydraulic cylinders 11 on the left and right sides are hinged on the machine head seat respectively. The left and right middle parts of the body 9, the piston rods of the opening and closing hydraulic cylinders 11 are linked with the hinges of the corresponding lock door 1, and the lock door 1 is rotated around the column pin 7 by pulling and pushing the lock door 1, thereby realizing the opening and closing of the compound machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com