Permanent magnet sub-suspension type tubular belt conveyor supporting device

A tubular belt type, supporting device technology, applied in conveyors, transportation and packaging, etc., can solve the problems of large energy consumption, vibration, unstable suspension structure, etc., and achieve the effect of reducing deviation and long-distance transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

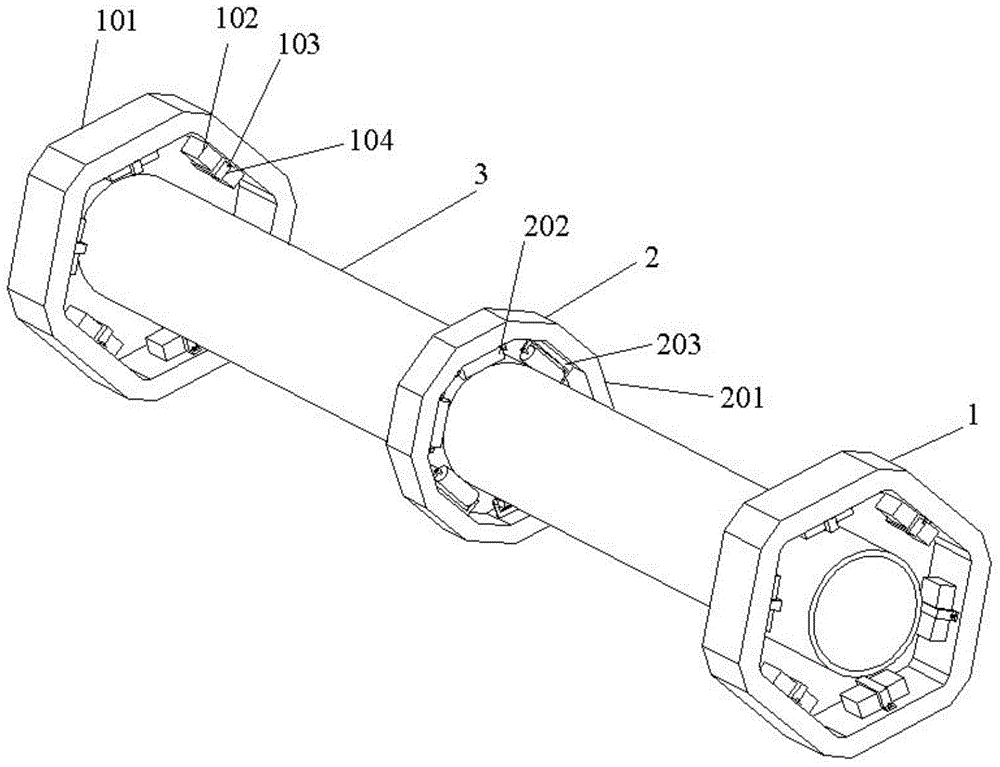

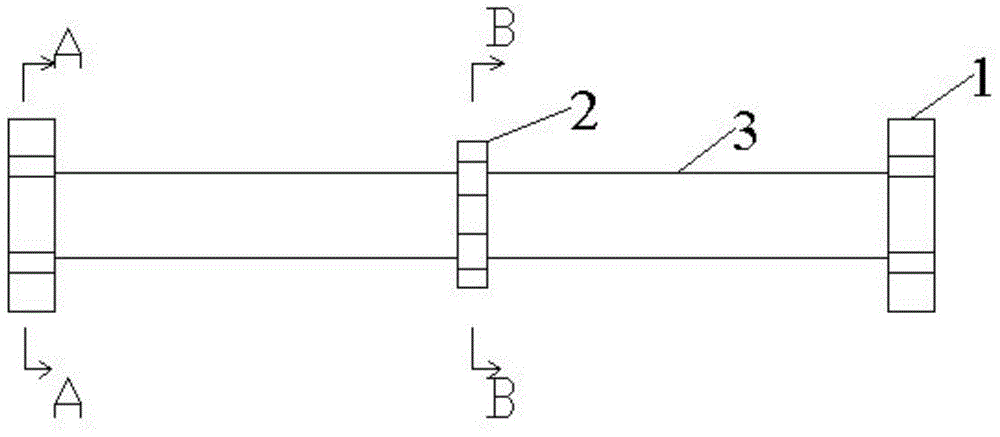

[0021] A permanent magnet sub-levitation type tubular belt conveyor support device, including a hexagonal magnetic support frame 1, an idler group support frame 2 and a tubular magnetic conveyor belt 3, one is arranged between every two hexagonal magnetic support frames 1 The support frame 2 of the idler group supports the tubular magnetic conveyor belt 3 by means of physical contact to prevent it from running off.

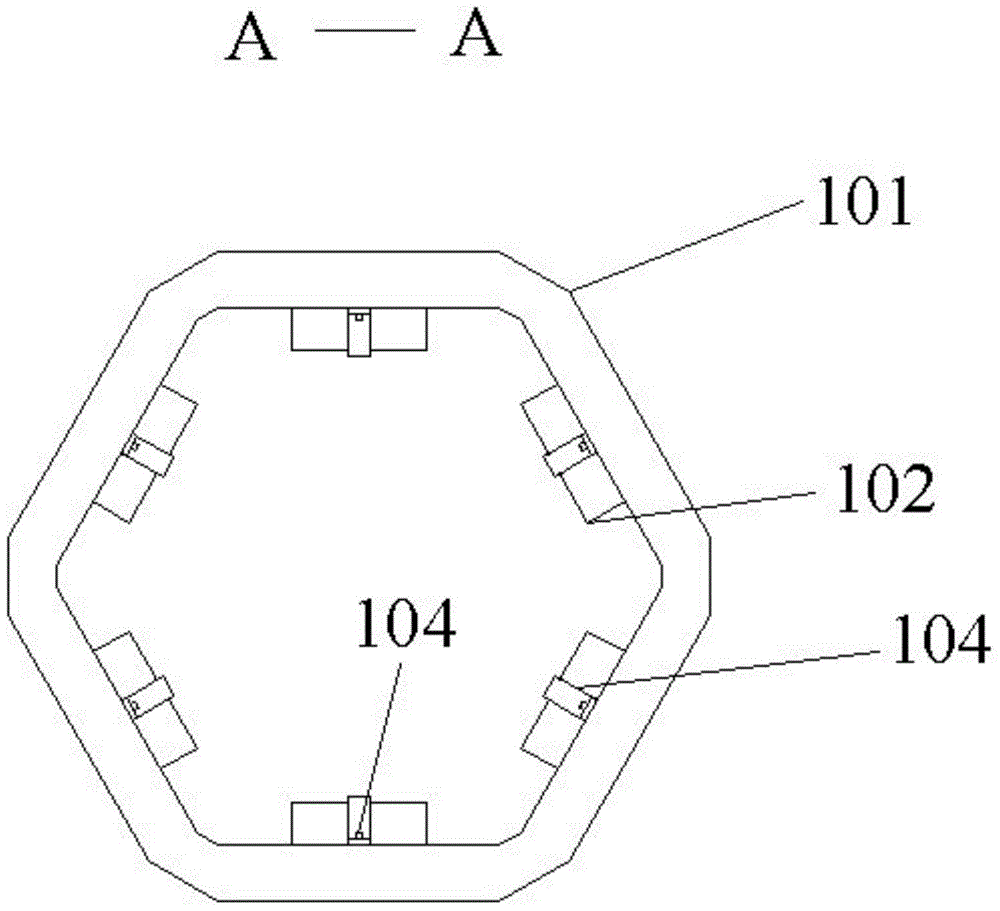

[0022] Described hexagonal magnetic support frame 1 comprises hexagonal antimagnetic frame 101, six cuboid permanent magnets 102, twelve antimagnetic screws 103 and six antimagnetic fixing parts 104; Described hexagonal antimagnetic frame 101 is six Hexagonal ring; each of the cuboid permanent magnets 102 is fixed on the hexagonal antimagnetic frame 101 by an antimagnetic fixing part 104 and two antimagnetic screws 103, and the described antimagnetic fixing part 104 is buckled on the cuboid permanent magnet 102 In the middle, a threaded hole is respectively opened...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap