Synchronous conveying balancer between devices, product conveying line and product production line

A technology of equipment room and balancer, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as production asynchrony, achieve continuous transportation, stable and reliable product transportation process, and increase the transmission speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

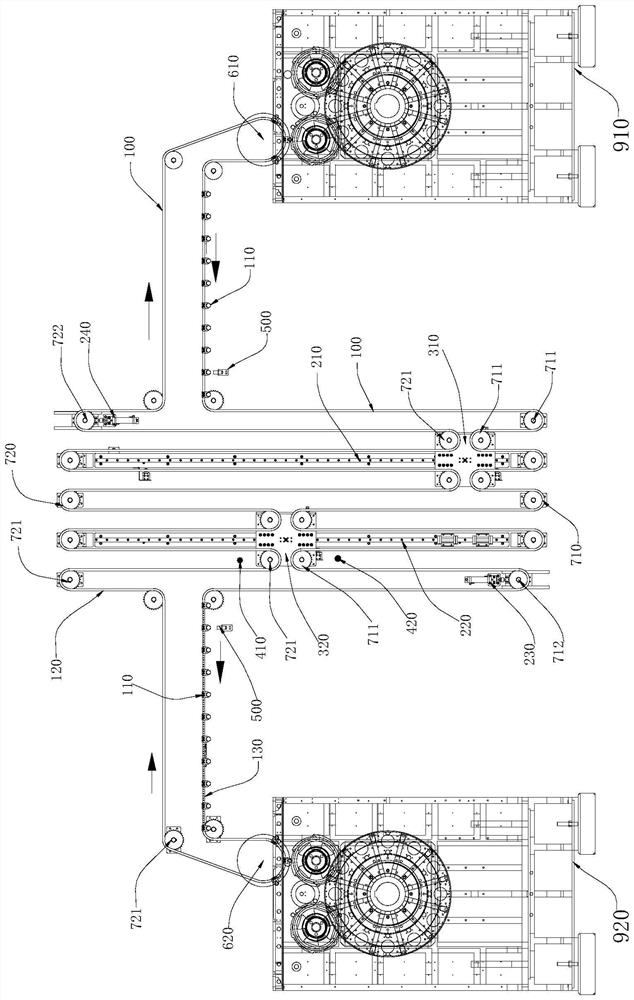

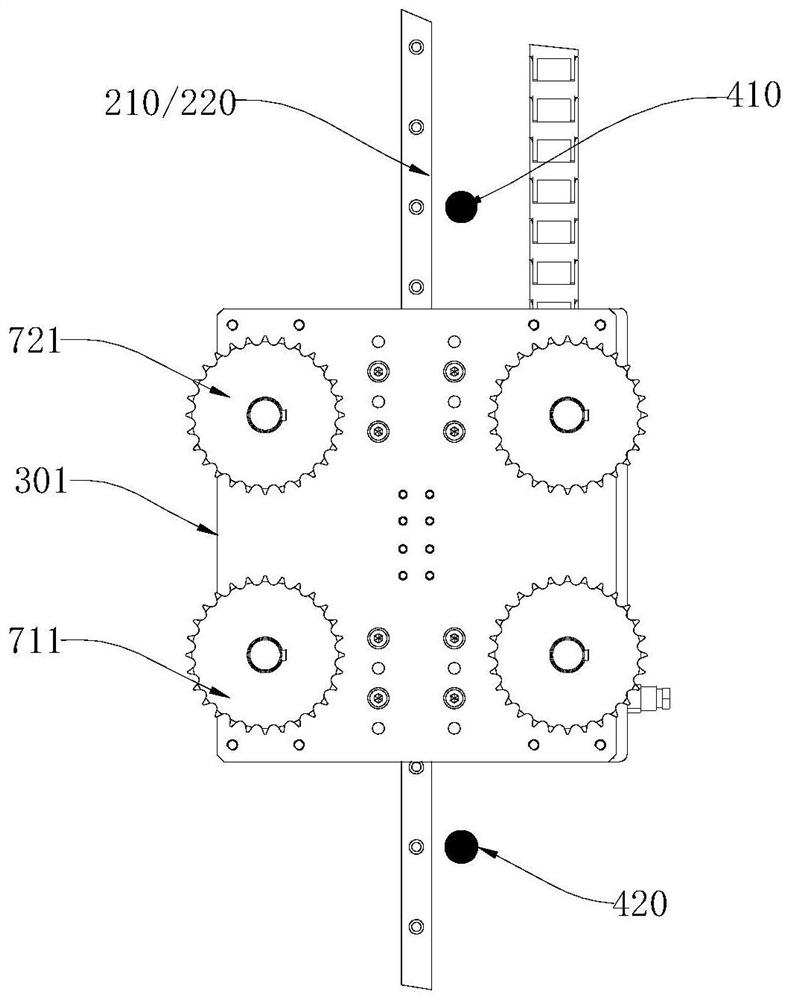

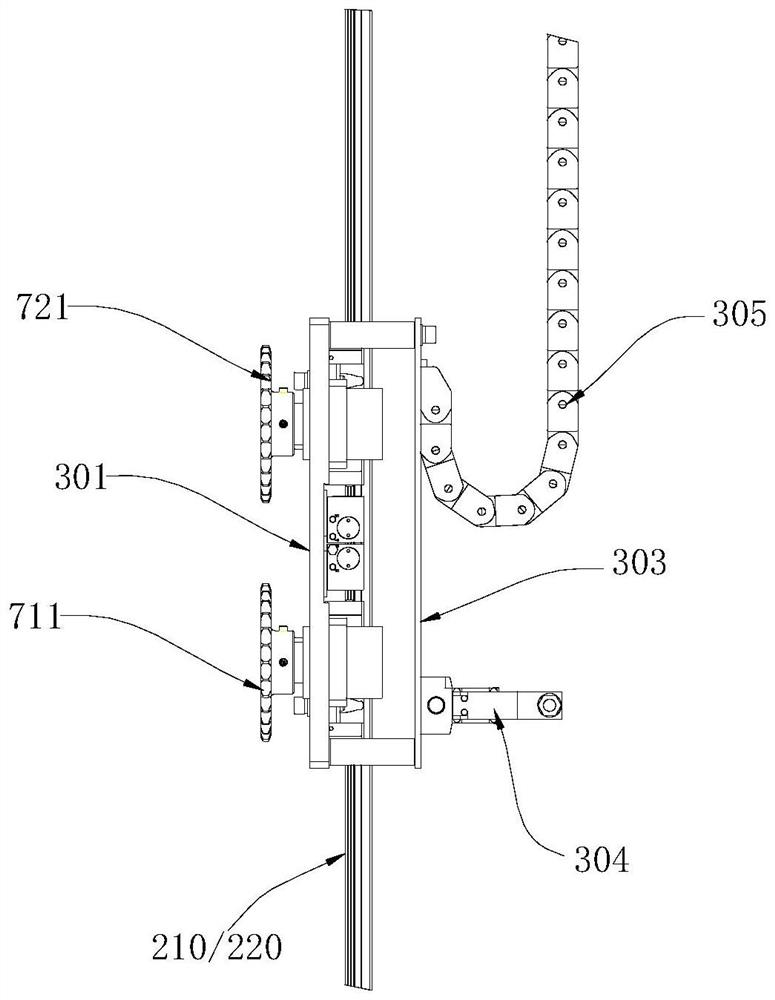

[0051] see figure 1 , a product conveying line with an inter-equipment synchronous conveying balancer, comprising a first rotary machine 910, a second rotary machine 920 and an inter-equipment synchronous transport balancer, the inter-equipment synchronous transport balancer is set on the first round between the rotary machine 910 and the second rotary machine 920 , and is used to transport the products output from the first rotary machine 910 to the second rotary machine 920 .

[0052] In this embodiment, the conveyor chain 100 of the inter-equipment synchronous conveying balancer is respectively connected to the first drive mechanism and the second drive mechanism of the first rotary machine 910 and the second rotary machine 920, that is, the equipment The power for the movement of the conveyor chain 100 of the inter-synchronous conveyor balancer is provided by the first rotary machine 910 and the second rotary machine 920, and the products output from the first rotary machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com