Conveying Machine Device

A conveyor and conveying path technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of manufacturing cost, increased installation space, insufficient deceleration time, maintaining a certain speed, etc., and achieve space saving , Smooth and reliable conveying, the effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Next, embodiments of the present invention will be described in detail with reference to the drawings, but the present invention is not limited to the embodiments shown in the drawings, and includes all embodiments that satisfy the requirements described in the claims.

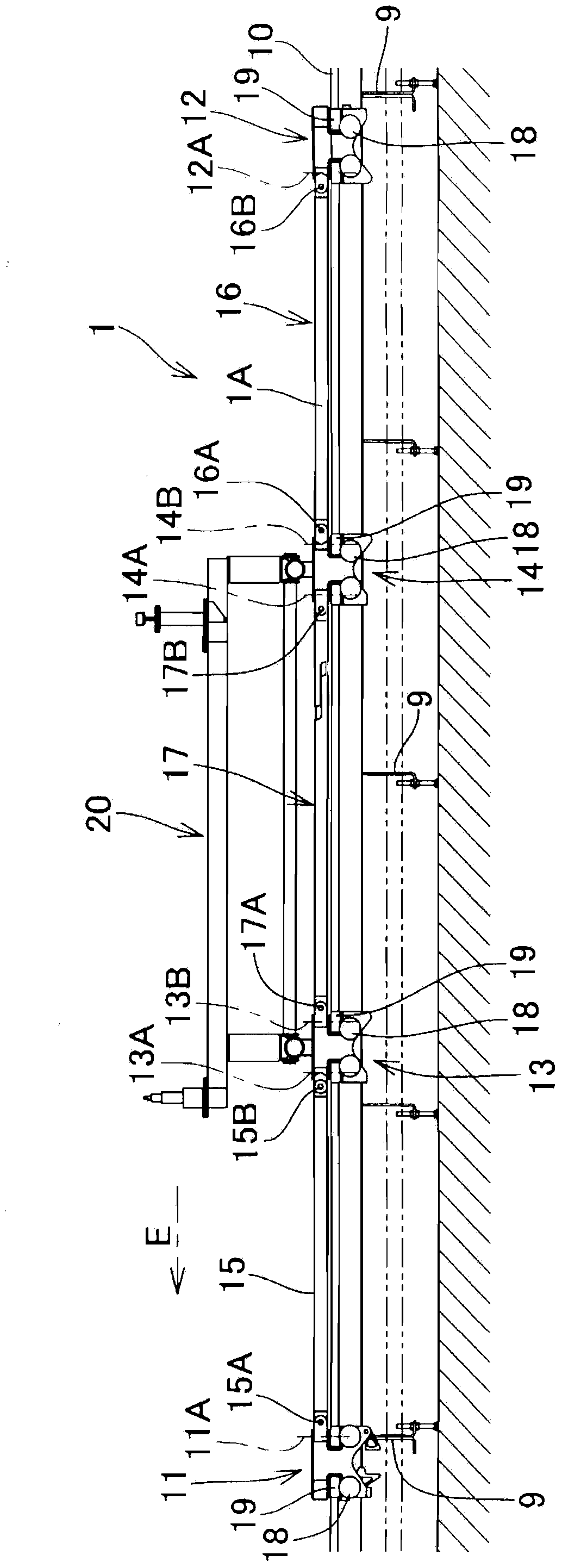

[0078] In this specification, along the transport direction E of the tray, the front side (downstream side) is referred to as front, the rear side (upstream side) is referred to as rear, and left and right are left and right in terms of facing forward. The figure viewed on the left serves as the main view.

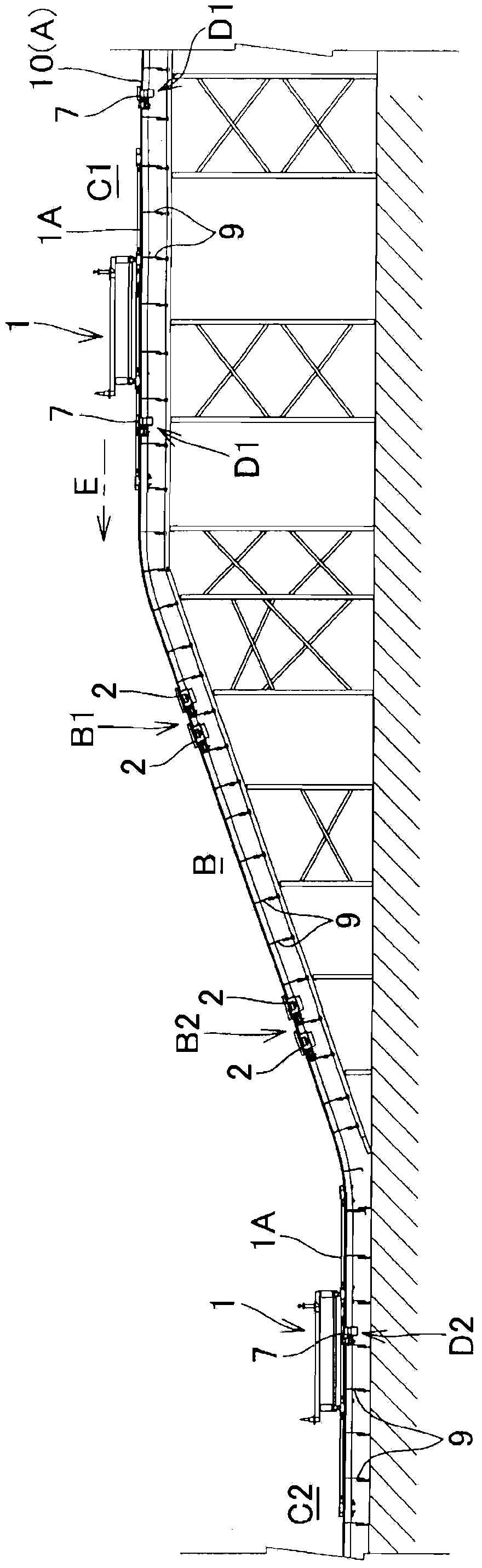

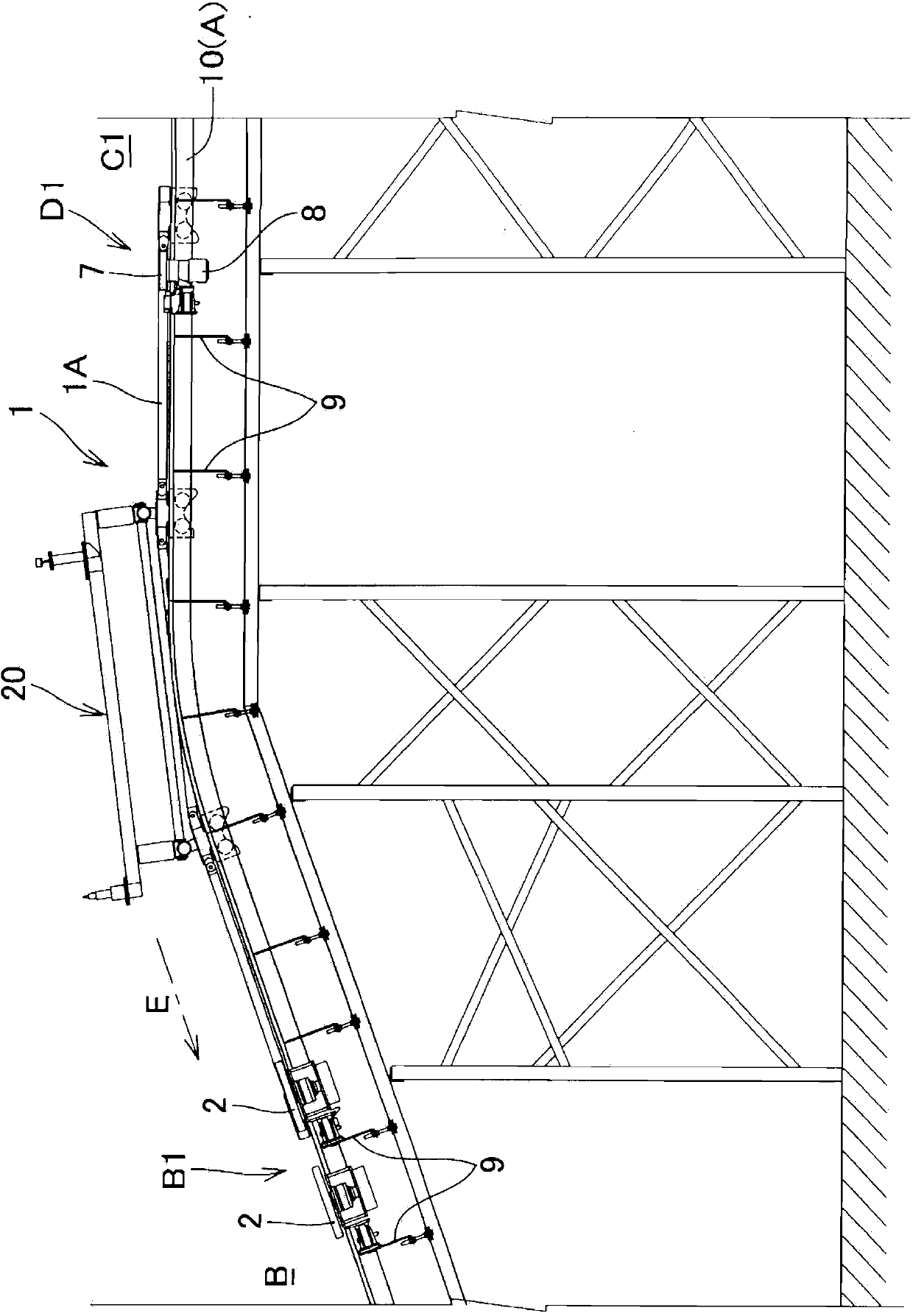

[0079] Such as figure 1 As shown in the front view of , the conveyor device according to the embodiment of the present invention is such that the carriages 1, 1, . . . , the carriages 1, 1, .

[0080] In the downward inclined path portion B, friction rollers 2 , which are friction members of non-powered braking members B1 and B2 , are in pressure contact with the friction-to-be-frictioned surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com